Amazingly small nanoscale buildings (Designed with DNA) are emerging from the research laboratories of Duke University and Arizona State University, and it is easy to imagine that you are browsing through the catalog of the smallest pots in the world.

A new book reveals some of the group’s creations: small pots, bowls and hollow bowls, hidden inside one another, as a home accessory for Russian nesting dolls.

But instead of using wood or clay to carve these things, the researchers used thread-like DNA molecules to carve these things, bend them and fit them into complex three-dimensional objects that are precisely on the nanoscale.

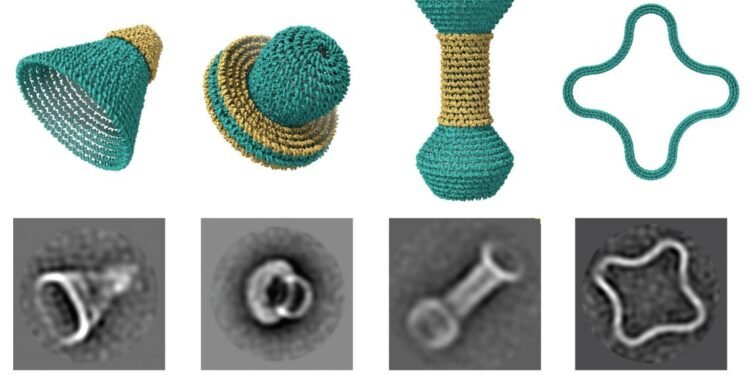

These creations demonstrate the possibilities of new open source software developed by a Duke Ph.D. student. Created by Dan Fu and his mentor John Reif. Declared Dec. 23 in the journal Science Advances, the software allows users to draw diagrams or digital models of circular shapes and turn them into 3D structures made of DNA.

The DNA nanostructures were assembled and mapped by co-authors Raghu Pradeep Narayanan and Abhay Prasad in Professor Hao Yan’s laboratory at Arizona State. Any small object with a hole is no more than two millionths of an inch in diameter. More than 50,000 of them can fit on a pinhead.

But the researchers say they are more than just nano-sculptures. The technology could allow researchers to create tiny containers for drug delivery or scaffolds for casting metal nanoparticles with different shapes for solar cells, medical imaging and other applications.

For many people, DNA is the blueprint for life; a genetic guide to all living things, from penguins to poplars. But for groups like Reif and Yan, DNA is more than a carrier of genetic information: it’s the source code and building material.

There are four “letters,” or bases, in the DNA genetic code, which come together in a predictable way in our cells to form the rungs of the DNA ladder. It is these strong elements that bind DNA – A and T and C and G – as the researchers confirmed. By engineering strands of DNA with specific sequences, they can “engineer” those strands to reassemble into different shapes.

This process involves converting one or a few single-stranded DNA strands, several thousand bases long, to a few hundred DNA strands that bind to complementary sequences in the long strand and “n” their” position.

Researchers have been experimenting with DNA as a building material since the 1980s. The first 3D models were simple cubes, pyramids, soccer balls – geometric shapes with solid, blocky elements. But designing architecture with curved surfaces that are close to natural is tricky. The goal of this group is to expand the spectrum that can be used with this method.

To do this, Fu developed a software called DNAxiS. Materials that build DNA sequences that were described in 2011 by Yan, who was a postdoctoral fellow at Reif and Duke 20 years ago before joining the faculty at Arizona State. It works by joining two long helixes of DNA into concentric rings that stack on top of each other to form the outline of the material, much like making a pot with clay fibers. To strengthen the structure, the team also made it possible to support them by supporting another layer for added stability.

Fu shows the variety of shapes they can take: cones, gourds, clover leaves. DNAxiS is the first software tool that allows users to create the shape in real time, using an algorithm to determine where to place short DNA “staples” to join the long DNA ring and hold the shape.

“If there are few of them, or they are in the wrong position, the system will not develop properly,” Fu said. “Prior to our software, the translation of forms made this a difficult problem.”

Given a sample of a mushroom, for example, the computer spits out a list of DNA strands that will associate themselves in the correct order. Once the strand is combined and mixed in a test tube, the rest takes care of itself: by heating and cooling the DNA mixture, in about 12 hours, “he turns on magical path into the DNA nanostructure,” said Reif.

Practical applications of their DNA modeling software in a laboratory or clinic could still be years away, the researchers said. But “it’s a big step forward in terms of automated design of new three-dimensional buildings,” Reif said.