Slow-motion movies and TV shows show sequences in hundreds of seconds. In contrast, nanoscale processes take place in the so-called femtosecond range: for example, an electron needs only a billionth of a second to orbit a hydrogen atom. Physicists around the world are using special instruments to capture these superfast nano-processes in movies, New research methods developed for nano and quantum materials.

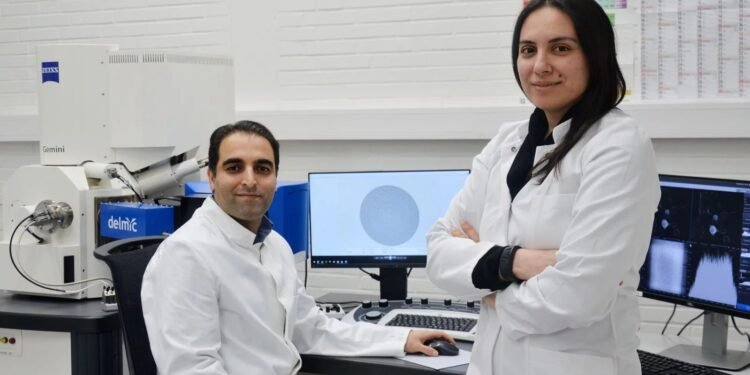

Researchers at the University of Kiel (CAU) have developed a new method for such films which is based on a different physical concept and thus allows deeper and more precise investigative options. To do this, they combined an electron microscope with a thin nanostructured metal layer that produces a small amount of light. In the first experiment, they were able to record the mutual interaction of light and electrons in semiconductors and films. Their results are published on February 23, 2023 in the famous scientific journal Nature Physics.

The new system is simpler and more effective

To date, films showing nanostructures have been rapidly produced using high-power lasers combined with electron microscopes. But only a few research groups can get a large and complex company. Nahid Talebi, professor of experimental physics at CAU says, “Our concept does not require expensive and complex lasers, and it can be easily replicated.

” Electron microscopes combine electrons into space, accelerate it, and direct it to a sample. Electronic methods that pass through a sample or display allow conclusions to be drawn about the properties of the material and its internal processes. “Electron microscopes have a much better resolution than optical microscopes and allow analysis at nanometer scale for the first time,” says Talebi. The special feature he developed also makes it relatively easy to improve the time resolution of electron microscopes and convert them to their ultrafast models. For this reason, nanoscale current patterns can be captured in ultrafast femtosecond-scale films without lasers.

With this latest publication, Talebi is not content to show that his method works. By her review user, Dr. Masod Tales, and it provides a test test of photons in electrons and semiconductor, which is described in specified in the process, tungsten diselenide, WSe2, is used for correspondence with the professor Kai Rossnagel, at the University of the Kiel.

The nanostructured metal emits a small amount of light

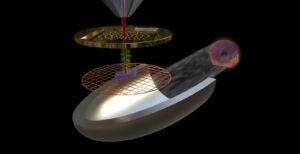

The key to Talebi’s idea is a unique nanostructure that resembles a kitchen sieve. It can be installed in an electron microscope, where it works as a light source, called “EDPHS” (electron photon source). When an electron beam strikes this metallic structure, the pattern of holes generates short, focused pulses of light that can be used to make fast movies. To create the special structure, the researchers drilled tiny 25 to 200 nanometer holes in thin gold foil. Talebi has calculated the size and distance correctly, because the light bulb uses only the spatial method. The \”nanossieves” were developed in collaboration with Dr. Mario Hentschel from the research group of Prof. Harald Giessen, University of Stuttgart. Together with colleagues from Amsterdam, Talebi had previously modified the electron microscope so that it can detect cathodoluminescence. These light signals are produced when fast electrons hit the metal.

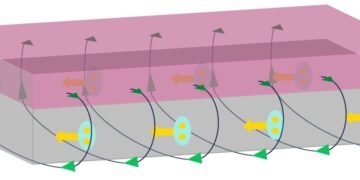

In the experiment described in the current issue, a small beam of light from the sieve like nanostructures hit the semiconductor sample at the speed of light. Here, they excite excitons, which are called quasiparticles. These are electrons that are separated from atoms and are still attached to the holes they created (“electron-hole pairs”). Talebi says, “If shortly after that, a slow electric current hits the semiconductor sample, we can see from the reaction of the electrons how the material reacts happening now,” Talebi says. The cathodoluminescence signal results from the density of the electron beam and light indicating the interaction between electrons and photons.

To be able to capture these processes on film, the researchers integrated piezoelectric crystals into a microscope setup. This allows them to change the exact distance between the light source and the sample, and thus the distance between the incident light and electrons. “In this way, the image can be taken at different times of the process and assembled into a film”, Talebi summarizes.