The world’s first 3D printing technology has been developed that can be used on transparent screens and AR devices, which perform physical activities that change the color of a chameleon or the beautiful color of a peacock’s wings.

Dr. Jaeyeon Pyo and KERI have succeeded in realizing a three-dimensional diffraction grating that can precisely control the path of light based on ‘nano-scale 3D technology living’. This is a new technology that can use the principles of visible color and nature for advanced display technology.

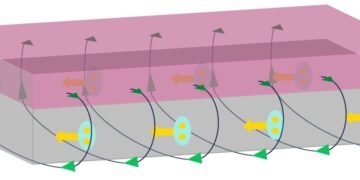

When light encounters the microstructure at a wavelength (1/100 to 1/1000 the thickness of a human hair), it refracts* and changes direction. In the case where the microstructure is regular, the wavelength of the light has a strong effect due to refraction, resulting in different colors called “structural colors”.

For example, in nature, the skin color of chameleons does not come from the combination of many pigments; instead, it occurs through changes in the microstructure, which leads to the production of color. Similarly, the beautiful colors of peacock feathers result from the specific arrangement of their internal microstructure.

* Diffraction: The phenomenon of light bending or spreading through space (space) when it encounters an obstacle. KERI’s achievement is the achievement of a “diffraction grating”, which can precisely control the color structure, and nanoscale 3D printing technology.

A diffraction grating is a device with a regular microstructure for the purpose of controlling the diffraction of light. When light is directed at it, the light reflects in different ways depending on the wavelength, creating different colors or patterns. In other words, it is the 3D printing technology that allows to control light effectively for coloring without dyes.

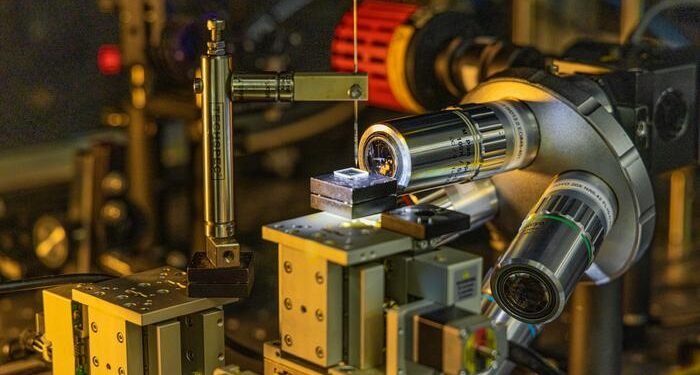

A fine diffraction grating is very important to control the diffraction of light whose wavelength is only 1/1000th the thickness of a human hair. KERI, which has the world’s best nanoscale 3D printing technology, has successfully printed a high-resolution nanowire diffraction grating using a new technique called ‘edge-printing’. This is done by moving the 3D printing nozzle as if sewing fabric to print the shape of the bridge (﹇).

Diffraction gratings should be shown in different high-resolution displays. Discovering the transparency of the diffraction grating itself, it can be used in a variety of future displays such as smart windows, mirrors, and head displays in cars.

There are also many applications for this technology in AR devices that use a diffraction grating as a key component. In addition, diffraction gratings can be designed to emit different colors depending on their shape, enabling the technology to be used in engineering and biomedical applications where problem diagnosis is required, and the diffraction grating itself can be used in ‘a lot of optical physics research.

Dr. Jaeyeon Pyo of KERI said that it is “the world’s first 3D printing technology that works perfectly with the desired color in the desired location without restrictions on the input material or shape.” He also said that this technology will be able to overcome the ‘Form’-Factor’ limitation of display devices to bring diversification.

The research was reviewed for quality and published as a cover article in ACS Nano, SCI’s leading materials science journal published by the American Chemical Society. The JCR impact factor, which measures the impact of a newspaper, is 17,100, placing it at 5.7% of its field.

KERI, which has completed the patent application for the first technology, hopes that this achievement will receive a lot of attention from the companies involved in the exhibition and plan to promote the transfer of technology by identifying companies that need this technology.

Source: Korea Electrotechnology Research Institute.