Mimicking the structure of the kidney, a team of scientists from Lawrence Livermore National Laboratory (LLNL) and the University of Illinois at Chicago (UIC) have created a three-dimensional nanometer (nm)-thin membrane that breaks the permeance-selectivity trade-off of artificial membranes.

Highly permeable and selective membranes are useful for a wide range of applications, such as dialysis, water purification and energy storage. However, conventional synthetic membranes based on two-dimensional structures suffer from the trade-off limitation between permeability and selectivity, arising from their intrinsically limited surface area and long complex pore geometries.

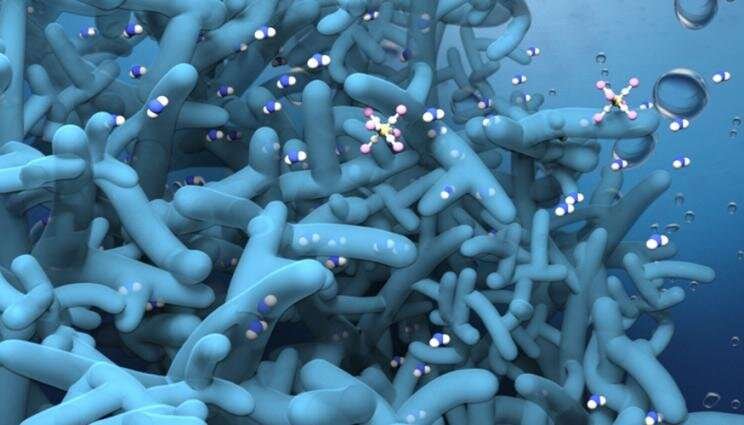

Taking a cue from biological systems that achieve a highly selective and rapid trans-membrane mass transport by employing efficient 3-D functional structures, the team developed a self-supportive 3-D membrane composed of two 3-D interconnected channels, which are separated by a nanometer-thin porous titanium-oxide (TiO2) layer.

This unique biomimetic 3-D architecture dramatically increases the surface area, and thus the filtration area, by 6,000 times, coupled with an ultra-short diffusion distance through the 2-4-nm-thin selective layer. These features provide the 3-D membrane’s high separation performance with fast mass-transfer characteristics.

“Our study suggests that the 3-D membrane design has great potential for overcoming the limitations of conventional synthetic membranes,” said LLNL materials scientist Jianchao Ye, one of the corresponding authors of a paper appearing in the journal Materials Horizons.

“The results of this work also provide fundamental design criteria for the development of high-performance nanoporous membranes,” said Sangil Kim, former LLNL scientist now at the University of Illinois at Chicago.

The team said the new 3-D membrane exhibits promising applications in biomedical engineering and the energy storage area, such as membranes for lithium-sulfide and lithium-oxide batteries.

“The 3-D biomimetic membrane design demonstrated in this work will ultimately enable the development of high-performance implantable hemodialysis systems and artificial membrane lungs, thus changing the life of hundreds of thousands of Americans with total and permanent kidney failure and lung failure,” LLNL scientist and co-author Juergen Biener said.

The team also pointed out that the performance can be further improved by geometrical optimizations using 3-D printing and machine learning techniques, which leads to tremendous research opportunities in the membrane field.