A novel three-dimensional (3-D) touchless interactive display can change color based on the distance of the user’s finger from the screen by detecting subtle shifts in ambient relative humidity, according to a new study. The technology may find future applications in wearable electronics and electronic skins (e-skins) that artificially mimic human skin’s ability to sense pressure, temperature, and humidity. While scientists have already developed a variety of interactive touch displays, most of these involve variations in the intensity of light emission or chromic reflection in response to a stimulus rather than changes in color, which can provide more striking and distinct visual feedback.

To develop a touchless interactive display based on changes in structural color, Han Sol Kang and colleagues in materials science, nano engineering and chemical engineering in the Republic of Korea and the U.S., designed a new display using chemically cross-linked, interpenetrated hydrogel network layers within photonic crystals that respond to changes in water vapor when a finger is moved from 1 to 15 millimeters from the surface. The process could shift the configuration of its surface structures to produce blue, green and orange colors. The researchers then demonstrated the possibility of easily transferring the photonic crystal-based film from one substrate to another by swapping it from a silicon surface to a printed one-dollar bill. By combining ionic liquid dopants (which alter a semiconductor’s electrical properties) as printing inks, the researchers note applications of the technology for printable and rewritable displays.

User-interactive displays (UIDs) facilitate the visualization of invisible information that can be sensed such as touch, smell and sound, with potential applications in wearable and patchable electronics suited for a futuristic hyperconnected society. The tremendous demand for electronic skin that can artificially mimic human skin to sense temperature, pressure and humidity has led to the development of a variety of human-interactive touch displays. A touch platform is in demand to visualize a stimulus without touch on 3-D interactive touchless displays. Kang et al. envision a stimuli-sensitive, low-power, reflective-mode, visible-range structural color (SC) of a photonic crystal (PC) to satisfy the engineering requirements of a user-interactive 3-D touchless display. The scientists developed a printable 3-D touchless interactive display using a hygroscopic ionic liquid ink with facile structural color variation relative to humidity. As proof of concept, they showed 3-D position-sensing of water vapor emanating from a human finger (humidity) for touchless display from finger to film, with emerging applications in wearable electronics.

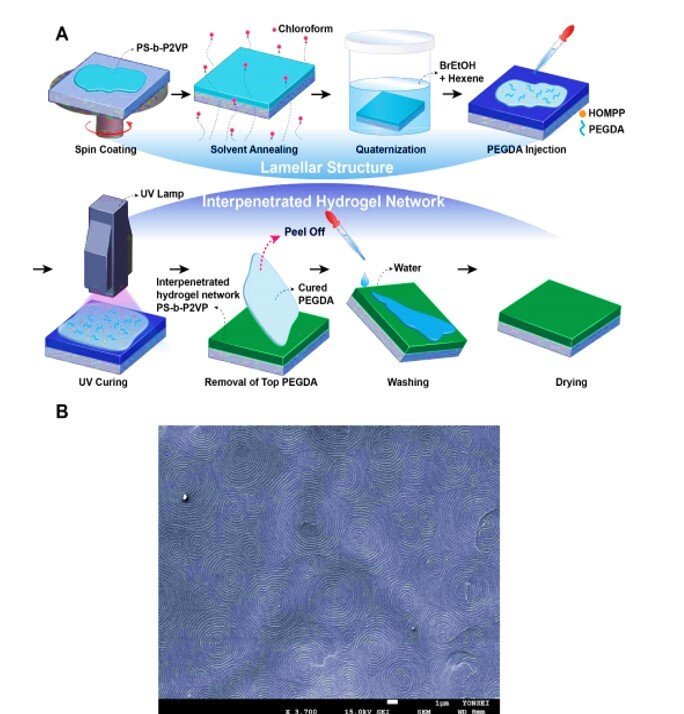

Developing an interpenetrated hydrogel network block copolymer photonic crystal (IHN BCP PC)

The team used self-assembled 1-D block copolymer (BCP) photonic crystals (PC) whose layered periodic microstructure developed spontaneously upon film formation. They then developed chemically cross-linked interpenetrated hydrogel network (IHN) layers in a BCP PC microdomain. Kang et al. controlled the amount of interpenetrated hydrogel network in the construct using UV irradiation to control its structural color (SC) across the full visible range. Using photographs of the engineered interpenetrated hydrogel network block copolymer photonic crystals (IHN BCP PCs), they showed the irradiation-dependent variation of SC. The polymer film was pseudoelastic (the material recovered completely after unloading large strains) with excellent mechanical robustness, flexibility and without sticky, gel-like viscoelasticity on the upper surface to make it suitable for solid-state sensing.

Characterizing the solid-state IHN BCP PCs

Kang et al. extensively characterized the solid-state construct using grazing incident small angle X-ray scattering (GISAXS) and transmission electron microscopy (TEM). The results showed the development of highly ordered 1-D photonic crystal structures and their calculated in-plane lamellae were consistent with finite-difference time-domain (FDTD) simulations. For cross-sectional transmission electron microscopy, they used cross-sectioned samples of the mechanically robust film via focused ion beam milling and noted the different layers of the material lamellae.

The TEM images of BCP films showed screw dislocations (defects in crystals) distributed across the sample surface to facilitate the transport of liquid and oligomeric agents into the BCP films. The BCP film allowed water molecules to diffuse through screw dislocations to facilitate humidity based touchless sensing. The team obtained additional mechanical properties including the effective modulus of the IHN BCP PCs using nanoindentation. The pseudoelastic material had an effective elastic modulus approximating 5.3 GPa—as expected and similar to those observed for conventional glassy polymers.

Obtaining full color display and developing a user-interactive 3-D touchless screen

To obtain a full color display, Kang et al. used an inkjet printer for direct deposition of an ink known as L-ethyl-3-methylimidazolium bis-(trifluoromethylsulfonyl)-imide, abbreviated EMIMTFSI, on an IHN BCP PC film. The color of the film depended on the amount of EMIMTFSI deposited in a given region. The inkjet printer only required a single ink for deposition on the IHN BCP PC film, which markedly differed from a commercial inkjet printer with red, green, and blue dye inks. Kang et al. produced a given colored image by first programming the appropriate color information into a black/gray/white contrast. As proof of concept, they converted a U.S. dollar bill to a black and white contrast using software, and reconstructed the full color structural color image using EMIMTFSI inkjet printing on an IHN BCP PC film.

For further applications of the IHN BCP PC display, Kang et al. used another hygroscopic ionic liquid named bis(trifluoromethylsulfonyl)amine lithium salt (abbreviated LiTFSI). Upon diffusion of this ionic liquid into the material, the structural color of the photonic crystal became sensitive to environmental humidity. The LiTFSI allowed association with water molecules for structural color variations to occur across the visible range as a function of humidity. The absorbed water could be diffused out in a reversible process. The setup allowed the human finger with natural humidity approximating 90 percent to be an excellent source to modulate the structural color of the display film, which the team confirmed experimentally. The 3-D touchless sensing display worked successfully under multiple sensing events with different finger-to-photonic crystal distances. Increased capacitance due to water uptake approximated a response time of 20 seconds and the reversible change in structural color lasted 55 time cycles.

In this way, Han Sol Kang and colleagues demonstrated a user-interactive 3-D touchless sensing display based on block copolymer photonic crystals with interconnected hydrogel networks (abbreviated IHN BCP PCs). The engineering technique allowed for mechanically soft and robust full-visible-range structural colors on a film with an effective modulus. The team combined the film with various ionic liquid printing inks to create printable and rewritable displays for 3-D touchless sensing through varying capacitance and structural color changes, to demonstrate a new approach for solid-state sensors and 3-D touchless displays.