3D LASER PRINTING WITH BIOINKS FROM MICROALGAE: HEIDELBERG Analysts Effectively Create A Modern Era OF BIOCOMPATIBLE MATERIALS FOR Added substance MANUFACTURING.

Microalgae such as the diatom Odontella aurita and the green alga Tetraselmis striata are particularly reasonable as “biofactories” for the generation of maintainable materials for 3D laser printing due to their tall substance in lipids and photoactive shades. An worldwide inquire about group driven by Prof. Dr Eva Blasco, a researcher at the Founded for Atomic Frameworks Designing and Progressed Materials (IMSEAM) of Heidelberg College, has succeeded for the to begin with time in fabricating inks for printing complex biocompatible 3D microstructures from the crude materials extricated from the microalgae. The microalgae-based materials might be utilized in future as the premise for inserts or platforms for 3D cell cultures.

Among the added substance fabricating strategies, two-photon 3D laser printing offers specific focal points for fabricating at the small scale- and nanoscale. Owing to its momentous determination, it finds application in various areas counting optics and photonics, microfluidics, and biomedicine. The handle includes centering a laser pillar on a fluid, photo reactive gum, a so-called “ink”. At the central point, the laser light actuates uncommon particles known as photo initiators and triggers a chemical response, causing nearby cementing of the ink.

To date, petrochemical-based polymers have been basically utilized as inks for this profoundly exact 3D laser printing prepare. Be that as it may, these polymers contribute to the consumption of fossil fills and the outflow of nursery gasses and can too contain harmful components, as Prof. Blasco focuses out. Microalgae are especially well suited as “biofactories” for the generation of feasible materials for 3D printing due to their fast development rate, CO2-fixation amid development, and biocompatibility. “Despite their preferences, microalgae have barely been considered as crude materials for light-based 3D printing,” says Prof. Blasco, whose bunch conducts inquire about at the interface of macromolecular chemistry, materials science, and 3D nanofabrication.

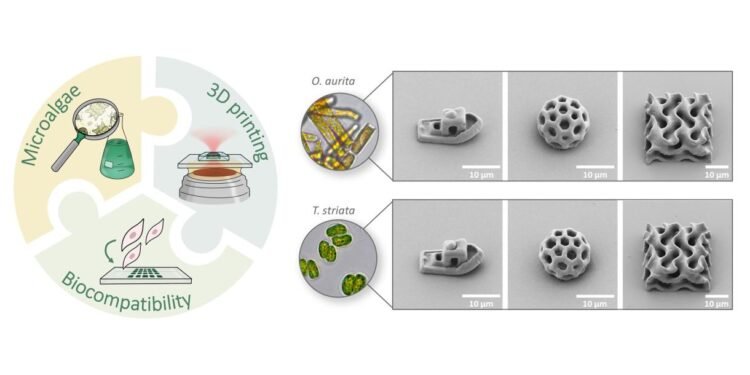

The investigate group succeeded for the to begin with time in extricating biocompatible materials for high-resolution 3D laser printing from microalgae. For their tests, the analysts chosen two species – the diatom Odontella aurita and the green alga Tetraselmis striata – that contain especially tall levels of lipids in the shape of triglycerides. The group extricated the triglycerides and functionalized them with acrylates to encourage fast curing beneath light light. The photoactive green colors display in the microalgae demonstrated to be reasonable as photoinitiators. When uncovered to light, they trigger the chemical response that sets the ink into a three-dimensional structure. “In this way we dodge utilizing possibly poisonous added substances like the photoinitiators utilized in customary inks,” clarifies to begin with creator Clara Vazquez-Martel, a doctoral candidate in Eva Blasco’s inquire about group at IMSEAM.

Using the modern ink framework, the analysts were able to create distinctive 3D microstructures with tall exactness, showing complex highlights such as overhanging rooftops and cavities. Utilizing cell culture tests, the analysts moreover examined the biocompatibility of the microalgae-based inks. They arranged 3D microscaffolds on which the cells were refined for around 24 hours. They watched a survival rate of nearly 100 percent. “Our comes about open up unused conceivable outcomes not as it were for more feasible 3D printing with light, but moreover for life science applications – from 3D cell societies to biocompatible implants,” says Prof. Blasco.

The investigate was conducted inside the Cluster of Brilliance “3D Matter Made to Order”, a collaboration of Heidelberg College and the Karlsruhe Founded of Innovation (Pack). This think about included analysts from Heidelberg, the Unit, and the Spanish Bank of Green growth at the College of Las Palmas de Gran Canaria (ULPGC, Spain). The work was financed by the German Investigate Establishment, the Carl Zeiss Establishment, the Fonds der Chemischen Industrie, and the European Union in the system of the European Regional Participation Program. The investigate has been distributed in the diary “Advanced Materials”.

Source: Heidelberg University