A pulsed-laser repetition rate of 57.8 GHz was achieved by inserting a resonator containing graphene. The limitations of the manufacturing process were overcome by directly synthesizing graphene onto standard copper (Cu) wires.

Pulsed lasers repeatedly emit light for a short period of time as if blinking. They have the advantage of focusing more energy than a continuous wave laser, whose intensity is kept unchanged over time. If digital signals are loaded in a pulsed laser, each pulse can encode one bit of data. In this respect, the higher the repetition rate, the more the amount of data that can be transmitted. However, conventional optical-fiber-based pulsed lasers have typically had a limitation in increasing the number of pulses per second above the MHz level.

The Korea Institute of Science and Technology (KIST) announced that the research team led by Senior Researcher Dr. Yong-Won Song at the Center for Opto-Electronic Materials and Devices was able to generate laser pulses at a rate at least 10,000 times higher than the state of the art. This achievement was accomplished by inserting an additional *resonator containing graphene into a fiber-optic pulsed-laser oscillator that operates in the domain of femtoseconds (10-15 seconds). The data transmission and processing speeds are expected to increase significantly by applying this method to data communications.

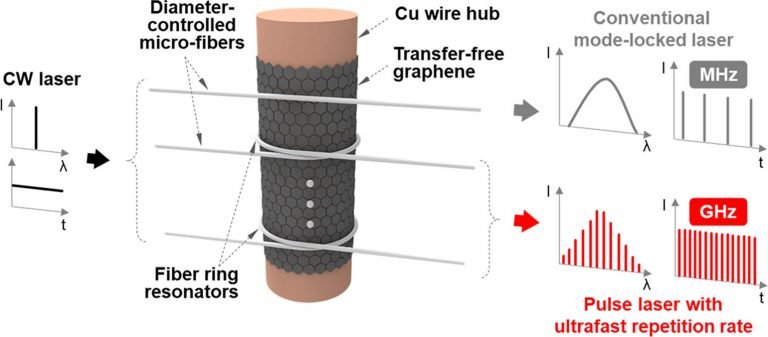

Graphene (Gf) was synthesized directly on the surface of a Cu wire that acted as a hub for diameter-controlled micro-fibers (DCMFs) to form the ring resonator. The Gf layer physically contacted with the DCMFs for the nonlinear interaction with fully minimized damage. Conventional Gf mode-locking scheme without a ring resonator is compared with the proposed scheme. Also, scalability toward multichannel operation is described. Credit: Korea Institute of Science and Technology (KIST)

The KIST research team noted that the characteristics of the wavelength and intensity of laser light that change over time are correlated (**Fourier transform). If a resonator is inserted into the laser oscillator, the wavelength of the pulsed laser is periodically filtered, thereby modifying the pattern of laser intensity change. Based on this background research, Principal Researcher Song synthesized graphene, which has the characteristics of absorbing and eliminating weak light and amplifying the intensity by passing only strong light into the resonator. This allows the laser intensity change to be accurately controlled at a high rate, and thus the repetition rate of pulses could be increased to a higher level.

Furthermore, graphene is typically synthesized onto the surface of a catalytic metal, and then the product is separated from the catalyst and transferred to the surface of a desired substrate. In this process, there has been typically the issue that graphene is damaged or impurities are introduced. The aforementioned KIST research team solved the problem of reduced efficiency occurring during the manufacturing process by forming graphene directly onto the surface of a copper wire, which is easily obtainable, and further covering the wire with an optical fiber for its use as a resonator.

As a result, it was possible to obtain a repetition rate of 57.8 GHz, thereby overcoming the limitations of pulsed lasers in terms of repetition rate, typically constrained to MHz. In addition, the characteristic of graphene such that heat is locally generated when the laser is absorbed, was exploited to tune the characteristics of the graphene resonator by applying an additional laser to the device.

Researcher Seong-Jae Lee at KIST said, “In the current scenario, in which the demand for data traffic is increasing exponentially, ultra-fast pulsed lasers operating at ultra-high speed and admitting tuning characteristics are expected to provide a new approach to adapt to this rapidly changing data-processing scenario.” Principal Researcher Song, who has led this research, added: “We expect that the development of ultra-fast pulsed lasers based on resonators and graphene will bring our lead in technology development and related market within the field of nanomaterial-based optical information devices.”