Tiny bubbles can solve large problems. Microbubbles—around 1-50 micrometers in diameter—have widespread applications. They’re used for drug delivery, membrane cleaning, biofilm control, and water treatment. They’ve been applied as actuators in lab-on-a-chip devices for microfluidic mixing, ink-jet printing, and logic circuitry, and in photonics lithography and optical resonators. And they’ve contributed remarkably to biomedical imaging and applications like DNA trapping and manipulation.

Given the broad range of applications for microbubbles, many methods for generating them have been developed, including air stream compression to dissolve air into liquid, ultrasound to induce bubbles in water, and laser pulses to expose substrates immersed in liquids. However, these bubbles tend to be randomly dispersed in liquid and rather unstable.

According to Baohua Jia, professor and founding director of the Centre for Translational Atomaterials at Swinburne University of Technology, “For applications requiring precise bubble position and size, as well as high stability—for example, in photonic applications like imaging and trapping—creation of bubbles at accurate positions with controllable volume, curvature, and stability is essential.” Jia explains that, for integration into biological or photonic platforms, it is highly desirable to have well controlled and stable microbubbles fabricated using a technique compatible with current processing technologies.

Balloons in graphene

Jia and fellow researchers from Swinburne University of Technology recently teamed up with researchers from National University of Singapore, Rutgers University, University of Melbourne, and Monash University, to develop a method to generate precisely controlled graphene microbubbles on a glass surface using laser pulses. Their report is published in the peer-reviewed, open-access journal, Advanced Photonics.

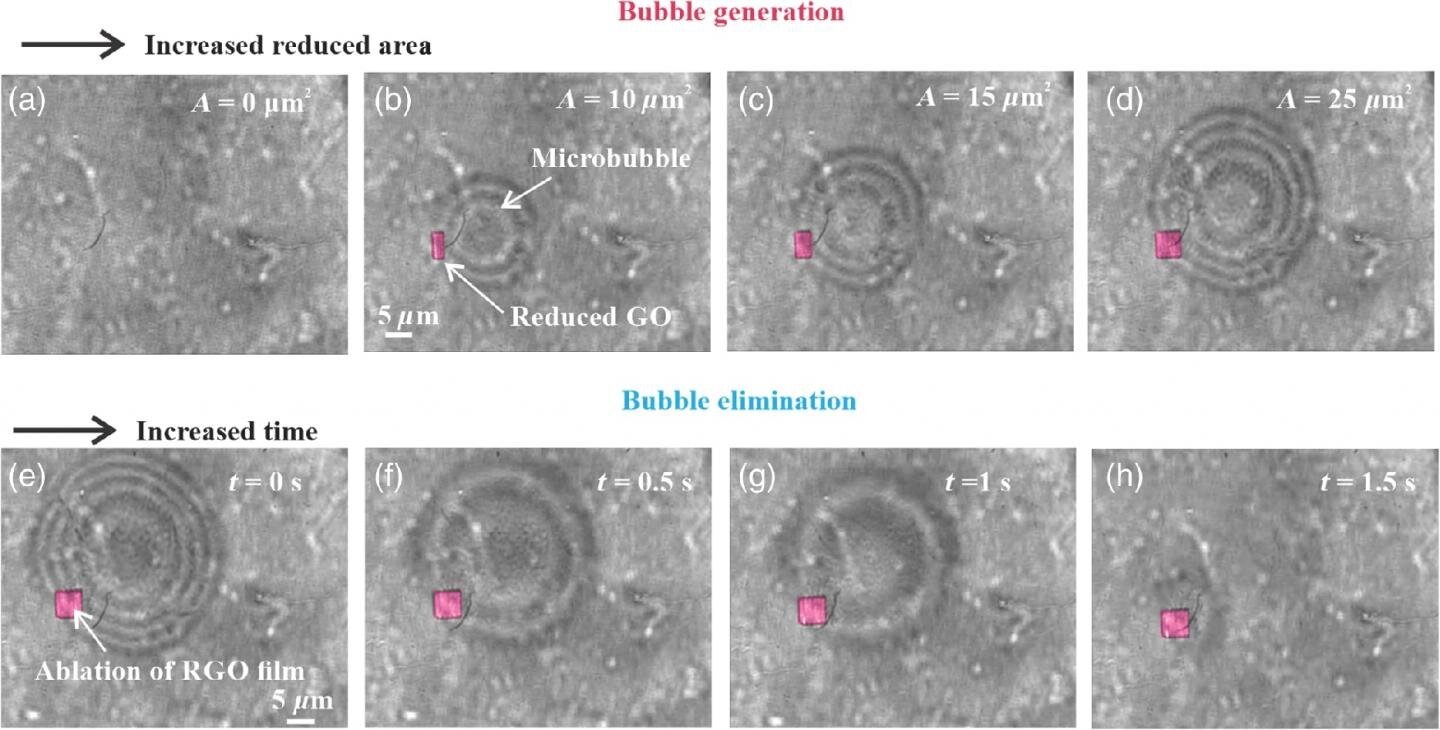

The group used graphene oxide materials, which consist of graphene film decorated with oxygen functional groups. Gases cannot penetrate through graphene oxide materials, so the researchers used laser to locally irradiate the graphene oxide film to generate gases to be encapsulated inside the film to form microbubbles—like balloons. Han Lin, Senior Research Fellow at Swinburne University and first author on the paper, explains, “In this way, the positions of the microbubbles can be well controlled by the laser, and the microbubbles can be created and eliminated at will. In the meantime, the amount of gases can be controlled by the irradiating area and irradiating power. Therefore, high precision can be achieved.”

Such a high-quality bubble can be used for advanced optoelectronic and micromechanical devices with high precision requirements.

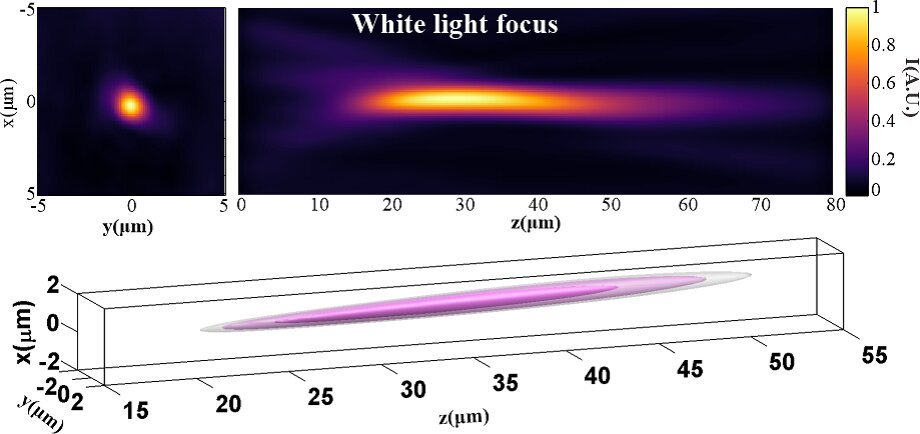

The researchers found that the high uniformity of the graphene oxide films creates microbubbles with a perfect spherical curvature that can be used as concave reflective lenses. As a showcase, they used the concave reflective lenses to focus light. The team reports that the lens presents a high-quality focal spot in a very good shape and can be used as light source for microscopic imaging.

Lin explains that the reflective lenses are also able to focus light at different wavelengths at the same focal point without chromatic aberration. The team demonstrates the focusing of a ultrabroadband white light, covering visible to near-infrared range, with the same high performance, which is particularly useful in compact microscopy and spectroscopy.

Jia remarks that the research provides “a pathway for generating highly controlled microbubbles at will and integration of graphene microbubbles as dynamic and high precision nanophotonic components for miniaturized lab-on-a-chip devices, along with broad potential applications in high resolution spectroscopy and medical imaging.”