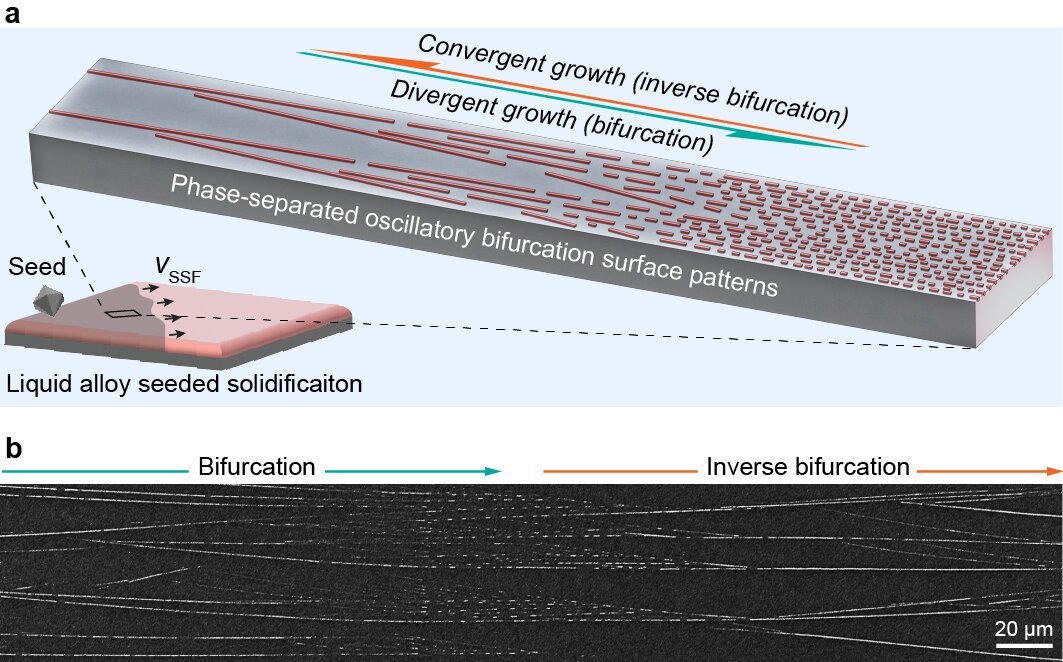

The researchers found that a Single silver-gallium system can produce distinct patterns such as particles or bundle-like structures of a Ag2Ga compound.

The team dissolved a small amount of metals such as silver (Ag) in low-melting-point solvent metals such as gallium (Ga), and investigated how the metallic components interact and separate to form patterns when the metallic liquid mixtures (alloys) solidify (Single silver-gallium system can produce distinct patterns).

Now, in work published in the journal Nature Synthesis, scientists from Australia, New Zealand, and the US reported a new type of solidification pattern that resembles the plots in the Chinese classic, but this time appearing on the surface of solidifying liquid metals.

The individual Ag2Ga structures that build the patterns are small, with micrometer or nanometer thicknesses, tens or hundreds of times thinner than a human hair.

Most surprisingly, the researchers observed that the patterns divide and unite in a repeated manner. “The first time I saw such cyclic divergent-convergent patterns, it immediately reminded me of the famous opening lines of the Romance of the Three Kingdoms,” said Dr. Jianbo Tang from University of New South Wales (UNSW, Australia), who is the first author of the study.

Pattern formation is a fundamental yet ubiquitous phenomenon which has interested and inspired scientists for a long time. Some pattern types are more common than others.

Among all the diverse patterning behaviors, divergent pattern formation, or bifurcation, is frequently seen in nature because this particular arrangement generally favors energy conversion or distribution. “I.e., it’s the ‘easiest’ path,” explains Dr. Tang. River networks, tree branches, lightning pathways, and vascular systems are all examples of bifurcation.

In comparison, convergent pattern growth, or inverse bifurcation, is encountered less frequently as it is contrary to the energetically favorable bifurcation.

The strange cyclic divergent and convergent growth, called oscillatory bifurcation, is rare and has not been observed in solidification structures prior to the new published work.

Despite this, the researchers observed oscillatory bifurcation patterns on the surface of several liquid alloys after solidification, which suggests that this counter-intuitive behavior is quite general for solidification patterns forming on the surface of liquid metals.

Analogous to the dramatized novel where the turbulent forces between and within a large number of power blocs drive those groups to divide and unite, the team found that it is also the instability of the liquid metal surface that underlies the emergence of the exotic oscillatory bifurcation patterns.

“Surface pattern formation of liquid metal alloys is a new but exciting topic. The surface or interfacial nature of the process enables us to better understand and control fundamental phase transition and pattern formation.” Dr. Tang added, “We will continue our work on designing crystalline surface patterns and structures using liquid metals to enable cutting-edge applications such as plasmonic sensing, high-efficiency electronics and optics, and high-precision spectroscopy.”

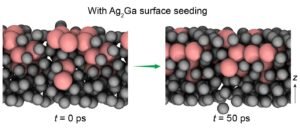

Initial and final (50 picoseconds) atomic configurations of the Ag atoms (pink) and Ga atoms (grey) seen in one of the molecular dynamics simulations. Credit: FLEET