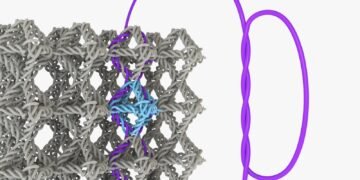

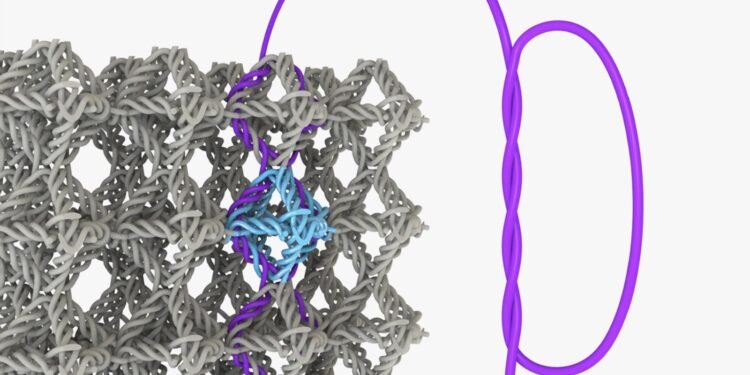

As part of new advances in nano- and micro-fabrication, Caltech engineers have developed a new material that consists of many microscopic nodes connected together.

Knots make the material stronger than similar things but not strings: they absorb more energy and are able to improve when they are able to return to their original shape without damaging it. Composite materials may find applications in biomedicine and aerospace applications due to their durability, biocompatibility, and high deformability.

“The ability to overcome the general trade-off between material deformability and tensile strength [the ability to stretch without breaking] provides new ways to design devices that are highly flexible, durable, and able to work in “under extreme circumstances,” says the former Caltech graduate student Widianto P. Moestopo (MS ’19, PhD \’22), now at Lawrence Livermore National Laboratory. Moestopo is the lead author on the nanoscale knots paper published on March 8 in Science Advances.

Moestopo contributed to the invention in the laboratory of Julia R. Greer, Ruben F. and Donna Mettler Professor of Materials Science, Mechanics and Medical Engineering; Fletcher Jones Foundation director of the Kavli Nanoscience Institute; and lead author of Science Advances. Greer is a pioneer in the creation of nano-architectural materials, that is, materials that are organized in their structure at the nanometer level and therefore exhibit unique, often surprising properties.

“Starting with understanding how fiber can affect the mechanical response of a micro-architectural material is a new concept that’s off the shelf,” Greer says. “We have done a lot of research in studying the mechanical deformation of many other types of micro-textiles, for example, mesh and woven materials. Delving into the world of ropes has given us insight into the role of friction and resistance, and has proven to be useful.”

Each link measures about 70 micrometers in height and width, and each strand has a radius of about 1.7 micrometers (about one hundredth the radius of a human hair). Although these are not the smallest particles that have been made – in 2017, chemists tied a third single strand – it represents the first time that a multi-stranded substance has been produced on this scale. Furthermore, it demonstrates the potential value of incorporating these nanoscale knots into materials, for example for suturing or tying in biomedicine.

Bonded materials, made from polymers, exhibit tensile strength that exceeds that of unbonded materials, including those where individual fibers are bonded rather than bonded together. Compared to their non-stringed counterparts, stringed materials absorb 92% more energy and require more than twice the force to break when pulled.

The fibers are not bonded but are manufactured in a bonded state using high-resolution 3D lithography that can create nanoscale structures. The models described in the journal Science Advances consist of a single string – a square string with an added beam that provides more tension to gain more energy as the object stretches. In the future, the group plans to explore objects built from complex nodes.

Moestopo’s interest in the bark grew out of his research in 2020 during the COVID-19 lockdown. “I saw work from researchers who were studying the structure of tissue fibers as opposed to fibers in a mathematical sense. I don’t consider myself a climber, sailor or mathematician, but I’ve been tied with rope all my life, so I think it’s worth trying to put rope into my creations.

Source: California Institute of Technology