A printable ink with an unsurpassed conductivity and transparency tradeoff has been developed by a KAUST team for use in solar panels, and for the novel blocking of electromagnetic waves.

Metals, such as copper and gold, generate little heat when a current flows through them. For this reason, these high-conductivity materials are used extensively in the electronics industry. Another property shared by these metals is opacity: they reflect light rather than transmitting it. But transparency is a useful property in electronic devices that generate, detect or manipulate electromagnetic radiation.

While there are materials that are both transparent and conducting, a compromise must usually be made. “A typical problem with optically transparent conductors is that their conductivity is low, and as transparency increases, the conductivity further deteriorates or vice versa,” explains electrical engineer Atif Shamim.

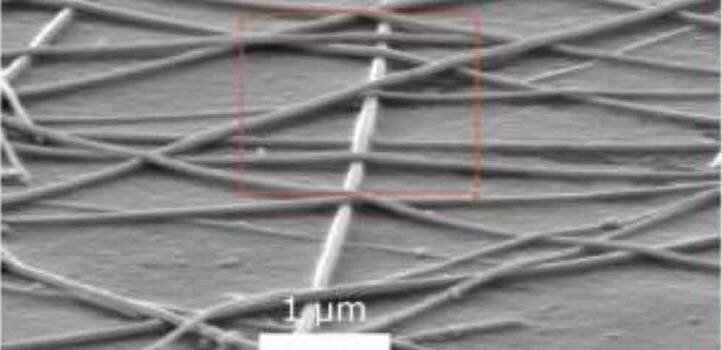

Shamim and Weiwei Li, a postdoctoral fellow in his group, developed the conductive ink by dispersing silver nanowires in a polymer solution. Working with another KAUST team led by Thomas Anthopoulos, they enhanced the optical and electrical properties of this ink using a treatment known as xenon flash-light sintering. “Silver nanowires are typically patterned through multiple processing steps and the patterning size is quite limited,” says Shamim. “We demonstrate the large-area and high-throughput patterning of silver nanowires in a single step.”

The ink could find important use in optoelectronic applications, such as solar cells. But Shamim and his colleague Khaled Salama used it in a device for another application: blocking electromagnetic waves. As society’s reliance on wireless communication grows, so do the dangers of system failures due to interference. And there are also unanswered questions about its impact on human health, particularly for newborn babies and vulnerable patients.

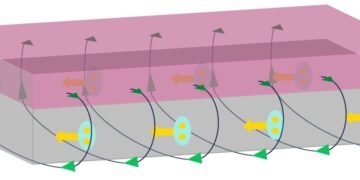

With these concerns in mind, Shamim and the team created a structure known as a frequency selective surface (FSS). As the name suggests, this reflects electromagnetic waves of a particular frequency, while letting others pass through it. The KAUST team made an FSS by depositing their custom-made conductive ink in a simple repeating pattern on a flexible polymer substrate.

Experimental characterization of the FSS showed decent reflection performance across two bands in the radio frequency part of the electromagnetic spectrum. And importantly, while typical FSSs only block waves with a certain polarization that come from a certain direction, the KAUST FSS was insensitive to the polarization of the radio waves and its performance was stable across a wide range of incidence angles. Another positive is that the printed FSS was completely flexible: its response did not deteriorate when the material was rolled up.

To demonstrate the real-world applicability of their shield, they placed a mobile phone in a box covered by the FSS and observed a significant reduction in the signal strength. “Based on these promising results, we are planning to extend our applications for flexible, transparent, high-performance electronic devices,” says Shamim. “For example, we want to apply the thin transparent FSS to a glass incubator in a hospital environment and conduct experiments of electromagnetic shielding to further characterize our design in a real environment.”