Due to the global trend of electric vehicles, the demand for next-generation batteries, Carbon fiber sheets for long-lasting electric vehicle batteries with higher capacity and faster charging than the current lithium-ion batteries has increased. Lithium metal batteries are not considered rechargeable batteries because lithium metal anodes have a capacity ten times that of commercial graphite anodes. However, during the charging and discharging process, lithium dendrites grow on the anode, causing poor battery performance and short circuits.

Dr. Sungho Lee, Director of the Carbon Composite Materials Research Center of the KIST Jeonbuk Institute of Advanced Composition Materials, and Professor KwangSup Eom of the Gwangju Institute of Science and Technology have developed a technology to improve durability by using carbon fiber as an anode, materials for lithium metal batteries.

The team published their findings in (Advanced Energy Materials, “The Construction of Hierarchical Surface on Carbon Fiber Paper for Lithium Metal Battery with Superior Stability”). Source: University of Amsterdam.

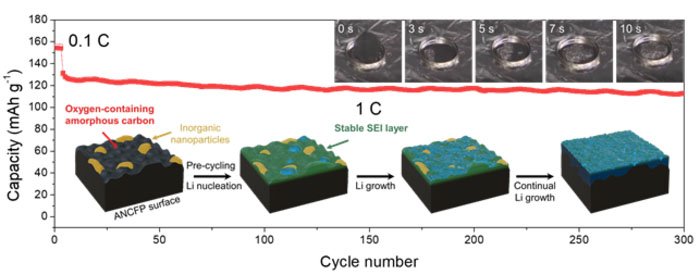

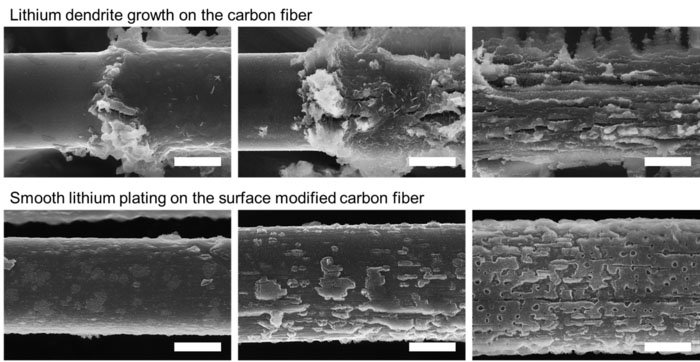

The KIST-GIST collaborative research team replaced the thin copper film coated with lithium with a thin sheet of carbon fiber containing lithium. The carbon fiber paper produced has a hierarchical structure and carbon monofilament, which consists of amorphous carbon and inorganic nanoparticles, which improved the synthesis of lithium and prevented the growth of lithium dendrites.

While the thin copper film short-circuits after about 100 cycles, the carbon fiber anode paper produced exhibits good cycle stability for 300 cycles. In addition, the lithium metal battery using carbon fiber paper produced shows a high energy of 428 Wh / kg, about 1.8 times higher than that using copper film (240 Wh / kg).

From a technical point of view, another advantage is to simplify the electrode production process, as the molten lithium is easily absorbed into the carbon fiber sheet.

Regarding the importance of this research, Dr. Sung-Ho Lee, Center Director of KIST, who led the research, said, “Considering a density that is five times lower and a lower cost of carbon compared to copper, the anode we need is something important which could lead to the commercialization of durable and lightweight lithium metal batteries.”

Source: Korea Institute of Science and Technology.