The addition of titanium makes the lighter work better, get more energy from the heat. When fossil fuels, but also biofuels, burn, a large part of the energy is lost in the form of waste heat. Heat exchangers can convert this heat into electricity, but they are not yet large enough for technical applications.

A group from the Max Planck Institut für Eisenforschung has increased the efficiency of heat exchangers by clarifying the effect of microstructure on the material and by improving the properties of the material by adding titanium.

The climate crisis forces us not only to get rid of fossil fuels, but also to conserve energy. Especially where fossil fuels cannot be replaced quickly, at least they should be used efficiently – for example, by generating electricity from heat from factories or factories power.

Currently, about 17% of the energy used in European factories is lost as heat. It can be made using thermoelectric material. In such generators, electrical voltage is generated when they are exposed to temperature differences. However, the current thermoelectric is not efficient enough to be used in many industrial applications.

A research led by the Max Planck Institute für Eisenforschung in Düsseldorf has been successful in improving the heat, because the materials are known in the technology, and thus come closer to industrial use. The team published their findings in the journal Advanced Energy Materials.

The team researched an alloy of niobium, iron and antimony that converts waste heat into electricity at temperatures from around 70 to over 700 degrees Celsius with an efficiency of 8%, making this alloy one in the best light bulb.

Only bismuth and tellurium compounds achieve similar values. However, bismuth telluride is suitable for use at low temperatures and is less stable than thermoelectric compounds of niobium, iron and antimony. In addition, its constituents are less readily available.

Titanium improves electrical conductivity

To further increase the efficiency of the thermoelectric composed of niobium, iron and antimony, the researchers focused on its microstructure. Like most metals, quartz is made up of small crystals.

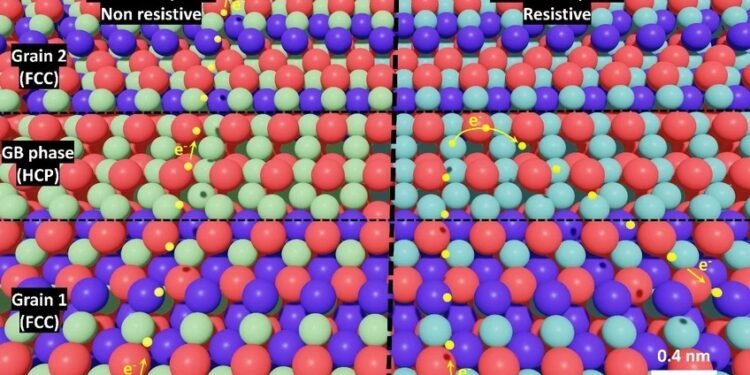

The composition and structure of the grains, as well as the characteristics of the space between them, which is called the grain size, is very important for the plant and the electricity of the furnace.

Previous studies have shown that grain size reduces both the thermal and electrical properties of materials. For the best performance, the thermal conductivity should be as low as possible so that heat, ie energy, remains in the material.

An electric heater, however, must be high enough to convert as much heat as possible into electricity. The aim of the group from the Max Planck Institute für Eisenforschung, Northwest University (USA) and the Leibniz Institute for Solid State and Materials Research Dresden is therefore to raise the grain size in such a way that only the thermal conductivity decreases, otherwise, Electrical conductivity Ruben Bueno Villoro, a PhD student at the Max Planck Institut für Eisenforschung explains,

“We used scanning electron microscopes and atomic scanning to examine the microstructure of the alloy down to the atomic level.

Siyuan Zhang, project manager explains, “Our research has shown that the amount of grain should be improved to improve the electricity and heat. “Because of the small yield of the material, the high number of the amount of grain makes the electricity worse,’ said Siyuan Zhang, project manager explains.

In one research group “It is not logical to increase the size of the grains in the material, because larger grains will increase the temperature and we will lose heat and therefore energy.

Therefore, we must find a way to increase electricity in a small matter. corn.” The researchers solved the problem by increasing the content of titanium, which, among other things, accumulates in the grain size and increases the electrical conductivity.

In this way, they increase the thermoelectric efficiency of the alloy up to 40%. For practical applications, however, the efficiency is still significantly increased.

The next step: The titanium grain size is selected to increase

Today, research groups are investigating ways to select titanium only in the grain size without making everything in titanium better.

This strategy reduces the cost and preserves the original chemical composition of the fuel. Current research shows how active materials can be combined with the atomic structure of materials to enhance specific properties.

Source: Max-Planck-Institut für Eisenforschung GmbH