An international team of scientists is developing an irreversible nanomaterial that they believe could one day become vaporizable electronics (‘Inkable’ nanomaterials promise huge benefits for bendable electronics) for displays and devices that are thin, light and compact.

According to the team, the material, zinc oxide, can be used in many areas of technology in the future, including mobile phones and computers, due to its transformation and recent advances in nanotechnology.

RMIT University Associate Professor Enrico Della Gaspera and Dr. Joel van Embden led a global team of experts to review the production process, capabilities, and potential applications of zinc oxide nanocrystals in Chemical Reviews magazine, a high-profile international journal.

Professor Silvia Gross of the University of Padua in Italy and Professor Kevin Kittilstved of the University of Massachusetts Amherst in the United States are the authors of the paper.

“Advances in nanotechnology have allowed us to improve and adjust the properties and performance of zinc oxide by making it smaller and with more specific properties,” said Della Gaspera, of the School.

Van Embden, who is also from the School of Science, said, “Different types of zinc oxide can be prepared with special control over their size, shape and chemistry at the nanoscale.”

“All these things lead to the correct management of the resulting materials (‘Inkable’ nanomaterials promise huge benefits for bendable electronics) for many applications in optics, electronics, energy, detection technology and even microbial decontamination.”

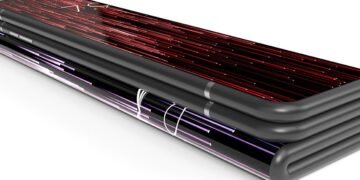

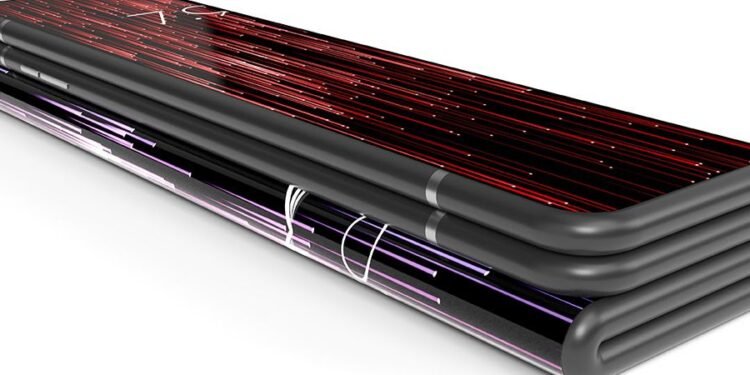

Vaporized electronic devices have a high mechanical strength

Zinc oxide nanocrystals can be formed into ink and deposited as a critical coating. This process is similar to inkjet printing or airbrushing, but the coating is hundreds of thousands of times thinner than the paint coating.

“These coatings can be made transparent to visible light, but also electrically efficient – two important characteristics for the production of touch screens,” said Della Gaspera.

Nanocrystals can be kept at low temperatures, allowing coating on flexible materials, such as plastics, that resist bending and bending, the team explained.

The team is willing to work with industry to explore applications that can use their process to create these nanomaterial coatings.

What is zinc oxide and how should I use it?

Zinc is an abundant element in the world’s minerals and is more abundant than many other metals related to technology including tin, nickel, lead, tungsten, copper and chromium.

“Zinc is already cheap and used by various industries, producing millions of tons per year worldwide,” said van Embden. Zinc oxide is a well-studied substance, with the first scientific discoveries being made since the early 20th century.

“Zinc oxide gained a lot of interest in the 1970s and 1980s due to advances in the semiconductor industry. With the advent of nanotechnology and advances in synthetic and research methods, zinc oxide has quickly become one of the most important materials of this century,” said Della Gaspera.

Zinc oxide is also safe, compatible, and is found in products such as sunscreen and cosmetics.

Possible applications, which are not electrically bendable, that can use zinc oxide nanocrystals include:

- Self-cleaning lid.

- Antibacterial and antifungal activity

- Sensor for detecting ultraviolet radiation

- Electronics in Solar Cells and Light Emitting Devices (LEDs)

- Transistor, which is a small device that controls electrical signals and is the basis of modern electronics.

- Sensors that can be used to detect harmful gases for residential, industrial and environmental applications.

Next step

Extending the team’s path from the lab to the manufacturing industry will require working with the right partners, Della Gaspera said.

“Scalability is a challenge for all types of nanomaterials, including zinc oxide,” he said.

“Being able to reproduce the same conditions we get in the laboratory, but in a much larger reaction, requires and repeats the type of chemistry used and the technological innovations in the reaction structure.”

In addition to these scalability challenges, the team will address the electrical deficiencies of the nanocrystal coating compared to industry benchmarks, which are based on complex physical applications.

The internal structure of the nanocrystalline coating, which allows it to change, limits the ability of the coating to conduct electricity well.

“We are working with other scientists around the world to solve these problems, and good progress is being made,” said Della Gaspera.

He sees great opportunities to work with other organizations and industry partners to solve these types of problems with perfect partnerships.