The authors, from the University of Geneva (UNIGE) and University of Lausanne (UNIL)—together with ETH Zurich (ETHZ)—show that the coating only consists of two ingredients: a protein called retinin and corneal wax. These two components automatically generate the regular network of protuberances by playing the roles of activator and inhibitor, respectively, in a morphogenesis process modeled in the 1950s by Alan Turing. The multidisciplinary team even succeeded in artificially reproducing the phenomenon by mixing retinin and wax on different kinds of surface. This process, which is very inexpensive and is based on biodegradable materials, was used to obtain nano-coatings with a morphology similar to that of insects, with anti-adhesive and anti-reflective functionalities that could have numerous applications in areas as diverse as contact lenses, medical implants and textiles.

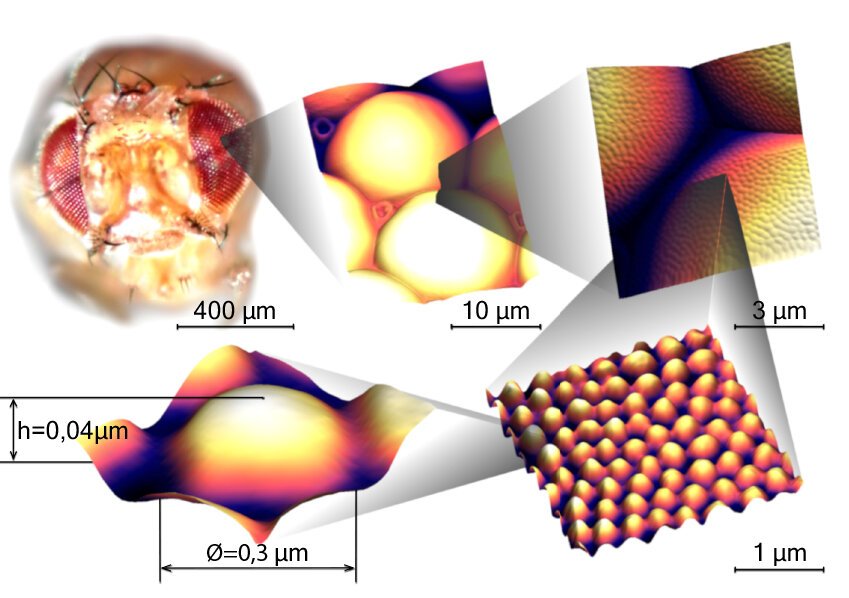

The nano-coating that covers the surface of the eyes of some insects was discovered in the late 1960s in moths, says Vladimir Katanaev, a professor in the Department of Cell Physiology and Metabolism in UNIGE’s Faculty of Medicine and the study’s lead investigator. It’s made up of a dense network of small protrusions about 200 nanometres in diameter and several dozens of nanometres in height. It has the effect of reducing light reflection.

The cornea of an insect without a coating typically reflects about 4% of the incident light, whereas the proportion drops to zero in insects that do have the covering. Although an improvement of 4% may seem small, it is enough of an advantage—especially in dark conditions—to have been selected during evolution. Thanks to its anti-adhesive properties, the coating also provides physical protection against the tiniest dust particles in the air.

Professor Katanaev moved into this research field ten years ago. In 2011, he and his team were the first to discover the nano-coating on the eyes of fruit flies (Drosophila melanogaster). This insect is much more suited to scientific research than moths, in particular because its genome has been completely sequenced.

Alan Turing: guiding light

Based on their preliminary results, in 2015 Professor Katanaev and his colleagues suggested that the nano-coating resulted from a morphogenesis mechanism that the British mathematician Alan Turing had modeled in the 1950s. This model holds that two molecules are organized automatically to produce patterns in regular patches or strips. The first serves as an activator, starting a process where a special pattern emerges and self-amplifies. But it also stimulates the second molecule at the same time, which acts as an inhibitor and is diffused more quickly. This model has made it possible to explain natural phenomena on a macroscopic scale—such as the spots on a leopard or the stripes on a zebra—and on a microscopic scale but never yet on the nanoscopic scale.

The Geneva-based researcher has now gathered more evidence to support this hypothesis. Thanks to biochemical analyses and the use of genetic engineering, Professor Katanaev and his colleagues have succeeded in identifying the two components involved in the reaction-diffusion model developed by Turing. This hinges on a protein called retinin and wax produced by several specialized enzymes, two of which have been identified. Retinin plays the role of activator: with its initially unstructured shape, it adopts a globular structure upon contact with the wax and begins to generate the pattern. The wax, on the other hand, plays the role of inhibitor. The powerplay between the two leads to the emergence of the nano-coating.

Artificial nano-coating

We subsequently managed to produce retinin at very low cost using bacteria genetically modified for this purpose,” says Professor Katanaev. “After purifying it, we mixed it with different commercial waxes on glass and plastic surfaces. We were then able to reproduce the nano-coating very easily. It’s similar in appearance to the coating found in insects and has anti-reflective and anti-adhesive properties. We think that we can deposit this type of nano-coating on almost any kind of surface, including wood, paper, metal and plastic.

Initial tests have shown that the coating is resistant to 20 hours of washing in water (it is easily damaged by detergent or scratching, although technological improvements could make it more robust). The anti-reflective properties have already aroused a certain degree of interest among manufacturers of contact lenses, while the anti-adhesive properties could appeal to the producers of medical implants. Indeed, this type of coating could make it possible to control where human cells hook on. Industry already has the techniques needed to obtain this outcome. But they use harsh methods, such as lasers or acids. The Geneva team’s solution has the advantage of being inexpensive, benign and totally biodegradable.