Being able to determine not only whether a micron particle is bent, but how much it can open up new avenues for machine vision and more. Micron-sized “bow extensions” self-assembled from nanoparticles to form a variety of curl shapes that can be controlled precisely, a University of Michigan-led research team showed.

The development paves the way for the easy production of materials that interact with curved light, providing new tools for machine vision and drug production. Although biology is full of twisted structures like DNA, known as chiral structures, the degree of rotation is locked – trying to change it breaks the structure. Now researchers can estimate the degree of torsion.

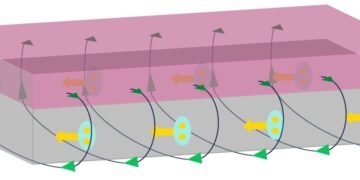

Such features may allow robots to navigate more efficiently in complex human environments. This curved structure will encode information in the form of light waves reflected from the surface, rather than a 2D array of symbols that include many human-readable symbols. This will take advantage of an aspect of light that humans cannot perceive well, known as polarization. The curved nanostructures effectively reflect certain types of light with a circular, curved shape as it travels through space.

“It is basically like polarization vision in crustaceans,” said Nicholas Kotov, Irving Langmuir University professor emeritus in chemical science and engineering, who led the study. “They collect a lot of information despite the dark environment.”

The robots can read signals that look like white spots on human eyes; The information will be kept in a combination of the frequency that is displayed, the tightness of the complex, and whether it is left or right.

By avoiding the use of natural and environmental light, relying on the ambient light produced by the robot, robots are not able to miss or interpret signals, whether in bright or dark environments. Selectable materials that reflect distorted light, known as chiral metamaterials, are often difficult to fabricate, but not archery.

“In the past, chiral metasurfaces were used for multi-million dollar applications. Now these complex materials can be printed with many interesting uses such as photography,” said Kotov.

Curved nanostructures can also help create the right conditions to create chiral drugs, which are difficult to create with precise molecular manipulation.

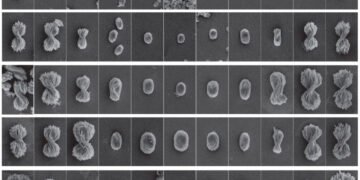

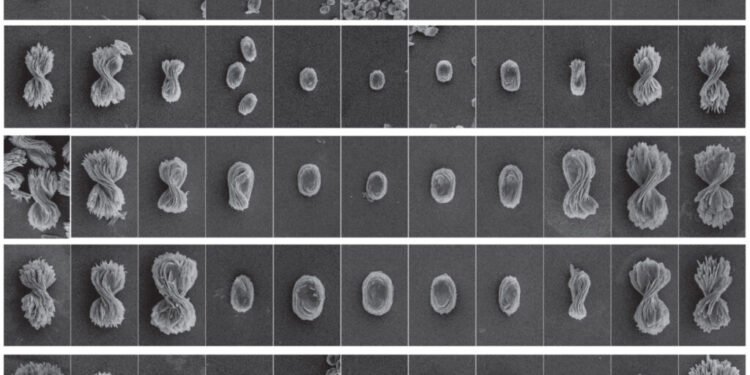

“Unprecedented in any chiral system is that we can control the torsion from a completely left-handed configuration to a flat pancake to a fully twisted configuration. We call it the continuum of chirality,” said Prashant Kumar, a postdoctoral researcher in chemical engineering and first author of the study in Nature.

Kumar experimented with bow strings as a form of paint, mixing them with polyacrylic acid and applying them to glass, cloth, plastic and other materials. Experiments with lasers have shown that this diagram reflects distorted light only when the deflection of the light matches the deflection of the bow.

Bow tie is made by mixing cadmium metal and cystine, a piece of protein in the left and right versions, in water that soaks lye. If the cystine is completely left-handed, a left-handed bow is formed, and a right-handed cystine produces a right-handed bow, each with a candy coating.

But with different proportions of left and right cystine, the team made a middle turn, including a flat pancake in a 50-50 ratio. The diameter of the strongest bowstring, actually the length of a 360 degree rotation, is about 4 microns in length, at the wavelength of infrared light.

“Not only do we know the progress from the atomic number to the micron level of the bow connection, but we also have the theory and the experiments that show us the forces that lead. With this basic understanding, you can design a bunch of other things,” said Thi Vo, a former postdoctoral researcher in chemical engineering at UM.

He worked with Sharon Glotzer, a co-author of the study, and Anthony C. Head of the Lembke Department of Chemical Engineering at UM.

Unlike other chiral nanostructures, which can take days to self-assemble, bowties form in just 90 seconds. The team produced 5,000 different types of bows. They used X-rays at Argonne National Laboratory before the research.

Source: University of Michigan.