Ph.D. candidate Jaleesa Bresseleers, of the TU/e department of Biomedical Engineering, investigated a robust and scalable manufacturing process for nanocarriers and their building blocks. With these insights, the road to widely available clinical applications for nanocarriers has become much shorter.

It’s common to read about amazing new drugs and therapies in the newspapers, only to have them disappear from the scene, never to be heard of again. The same usually happens for novel therapeutic nanoparticle formulations, usually nanocarriers that can be imagined as tiny balloons with a drug inside. One reason for this is that during scale-up toward industry applications, it is found that these formulations can’t be reproducibly and cost-effectively produced on a large scale, or even at all. Since nanocarriers are built from multiple tiny building blocks, Jaleesa Bresseleers studied how these building blocks and their formulation and processing parameters correlate to the resulting nanocarrier characteristics.

Understanding the process gives control over the results

Bresseleers and coworkers found that by slightly adjusting the building blocks, they could directly influence the size of the resulting nanocarriers. Simple processing parameters such as concentration, solvent usage and mixing rates also had an influence on the resulting size of the nanoparticles. These results provided her with the ability to precisely tailor nanoparticles towards specific sizes.

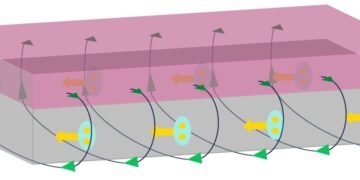

Then, she investigated the processing parameters in more detail using microfluidics. This technique provided even more precise regulation of mixing rates by controlling minute fluidic volumes. Bresseleers used it to obtain even better control over the resulting nanoparticle sizes, and was able to produce nanoparticles with different morphologies.

Ready for production at scale

With this knowledge, Bresseleers developed an efficient, scalable and highly controlled manufacturing process. To ensure product quality and consistency, the quality requirements of the European Medicines Agency (EMA) and U.S. food and drug administration (FDA) were constantly taken into account. In the end, she developed a continuous flow process for the large-scale production of drug-loaded nanoparticles that can be readily translated to clinical-scale production.

This research is an important step to take nanoparticle formulations towards a clinical product. It underscores how, as a general approach, it is important to critically assess the formulation and processing parameters at an early stage of nanoparticle design. Eventually, this will result in the creation of nanoparticles with impact that extends beyond the conceptual phase.