By Dr Yashwant R Mahajan

It is a matter of a great importance and concern that the energy use for heating and cooling in the building sector accounts for a sizeable part of the world’s total energy use (mainly using fossil fuels) and greenhouse gas emissions. According to world Economic Forum (WEF) there is a huge demand to improve the energy efficiency of Buildings which are responsible for 40% of global energy consumption and 33% of greenhouse gas emissions.

Therefore, it is imperative to develop and use mechanically robust and high performing thermal insulators which can be produced at a lower cost with lower embodied energy than the prior art, which is crucial to energy savings in buildings and sustainable development. Moreover, thermal insulation is crucial in climates, where heating and/or cooling is indispensable, especially in the situations where highly abundant renewable energy sources cannot be provided.

Silica aerogels are widely recognised as the world’s lightest solid materials. Silica aerogel contains over 90% of air by its volume, with the remaining 10% comprising silica nanoparticles which form an amorphous, cross-linked, three-dimensional silica network (Silica aerogel as super thermal and acoustic insulation materials). Due to such a high porosity value, silica aerogels are highly unique materials with a wide spectrum of fascinating properties, particularly their tunability to adopt transparent/translucent/opeque structure and extremely low thermal conductivities (0.008-0.011 W/mK), low densities (0.06-0.15 g/cm3), high porosity (>90%) and excellent sound damping capacity make them ideally suited for thermal insulation of buildings. Incorporated in composites or structural framing systems, they reduce the overall weight of the building exterior enclosure while increasing its thermal resistance, being especially valuable for energy-efficient retrofitting solutions, ranging from covering façades to window panes.

As mentioned above, the major advantage of silica aerogel as a thermal insulation is enhanced energy efficiency and, in turn, reduced hazardous emissions resulting from energy consumption.Silica aerogels have a relatively high compression strength, but are extremely fragile in nature due to their very low tensile strength. Moreover, they are neither biodegradable nor biocompatible in nature.To overcome this drawback, silica aerogels are frequently combined with other materials producing composite materials to improve mechanical strength while retaining aerogel’sdesirable properties such as low thermal conductivity. In addition, they also suffer from scale-up and sustainability issues. Silica aerogels are available in two different forms, namely: blankets and boards; and aerogel granules, but both the forms of aerogels are quite expensive, granules are usually cheaper than boards and blankets, starting at roughly 2500 EUR/m3, whereas the latter cost typically upward of 5000 EUR/m3 in Europe (The economics of thermal superinsulation in buildings).

Currently available super insulating materials (SIMs)are vacuum insulation panels (VIPs); silica aerogels;gas filled panels (GEPs), polyisocyanurate foams (PIR);Nano Insulation Materials (NIMs) based on hollow silica nanospheres (HSNS-Lab scale); and fumed silica boards. Although, SIMs exhibit superior thermal performance they are quite costly, non-biodegradable and can not be recycled.

In addition to the above, research is being directed to develop novel materials (The High-Performance Thermal Building Insulation Materials and Solutions of Tomorrow) like NanoCon which is basically a homogeneous material with a closed or open nanoporous structure with a typical thermal conductivity value of less than 4 mW/(mK) and possesses the requisite structural properties that are as good as or better than concrete. However, this is still under development.

In view of the above mentioned facts, scientists are exploring avenues to develop super insulating materials based on inexpensive,eco-friendly and natural materials. Luckily, nature has gifted in abundance the mankind with eco-friendly, renewable and cost-effective cellulose composite in the form of wood, which naturally possesses desirable self-organized molecular structure that is amenable to process into a strong nano structured super insulating material.

Currently, two major approaches, bottom-up and top-down, are being applied in fabricating wood-based functional materials. In the bottom-up approach, involves a series of mechanical and chemical processes for breaking down the cellulosic fibers of wood into nanofibrils and reassembling them into various macroscopic structures (Anisotropic, lightweight, strong, and super thermally insulating nanowood with naturally aligned nanocellulose). However, currently, this reassembling process results in most of the times in fibrils organized in randomly oriented structure. This approach is time-consuming and energy intensive and usually results in aerogels with isotropic structural properties. These insulating products show poor mechanical properties that has prohibited their widespread application in building sector.

Top-down modification approaches take benefit of the pre-existing cell wall nanostructure and hierarchical porosity (microscopic pore channels at the centre of fiber cells, and nanopores within the cell wall), while preserving the anisotropy of oriented fibres (Structure-property-function Relationships of Natural and Engineered wood). This porosity provides opportunity for a great variety of functionalization approaches, at different scales. Such top-down approaches have enabled to innovate unique wood-based functional materials with improved or endowed with even entirely new properties and functions, and thereby, largely expanding the application fields of wood.

In one of the top-down approaches, investigated by the researchers from University Maryland, College Park, USA, the wood aerogel was prepared by subjecting natural wood to a simple chemical treatment with H2O2,Na2SO3,NaOH,or acetic acid.The chemical treatment, resulted in the removal 0f lignin and hemicellulose fromthe natural wood, while the alignment of cellulose nanofibers was maintained intact, leadingto a layered structure of the wood aerogel.

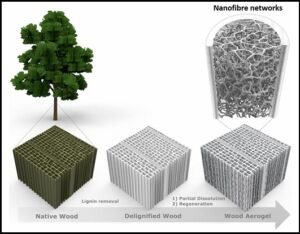

The layered structure endowed the anisotropic wood aerogel with a good mechanical compressibility and fragility resistance.Additionally, the anisotropic structure of the wood aerogel with curved layers stacking layer-by-layer and the presence of aligned cellulose nanofibers within each individual layer provides the wood aerogel with an anisotropic and super thermal insulation property, holding significant promise for potential applications in the field of thermal management (Highly Compressible, Anisotropic Aerogel with Aligned Cellulose Nanofibers). Figure 1 schematically presents the various steps involved in the process.

Figure 1) Schematic and photographic illustration of the wood aerogel (a) Graphical illustration of the highly compressible, anisotropic woodaerogel directly fabricated from natural wood via a simple chemical treatment.

Reprinted and adapted with permission from (Highly Compressible, Anisotropic Aerogel with Aligned Cellulose Nanofibers, Highly Compressible, Anisotropic Aerogel with Aligned Cellulose Nanofibers, Jianwei Song, Chaoji Chen, Zhi Yang, et al., ACS Nano, American Chemical Society, Jan 1, 2018, https://doi.org/10.1021/acsnano.7b04246), Copyright © 2018, American Chemical Society.

In essence, the top-down approach is low-cost, scalable, simple, yet effective, representing a promising direction for the fabrication of high-quality aerogel materials. However, in the above processing routeit was found that this type of wood aerogels show low specific surface area (<50 m2/g, which is not comparable with nanocellulose-based aerogels) as well as empty fiber lumen (diameter ∼30 μm), which leads to inferior thermal insulation in the axial direction.Therefore, limiting their roles in advanced applications (Nano structurally Controllable Strong Wood Aerogel toward Efficient Thermal Insulation). The problem can be solved by introducing the nanoporosity in the lumen space, can effectively reduce gas convection and conduction, enabling the material to achieve a thermal conductivity below that of stationary air, and thereby improve thermal insulation performance (Critical roles of pores and moisture in sustainable nanocellulose-based super-thermal insulators).

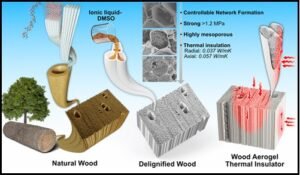

In order to overcome the above mentioned problem of the presence of poor thermal insulation in axial direction, a team of researchers from KTH Royal Institute of Technology and Uppsala University, Sweden have followed a preparation technique (Top-Down Approach Making Anisotropic Cellulose Aerogels as Universal Substrates for Multi-functionalization) which consisted of nanoscale removal of lignin, followed by dissolution−regeneration of nanofibers using dimethylacetamide/lithium chloride (DMAc/LiCl), leading to reduced cell wall porosity with nano fibrillated networks occupying the pore space in the cellular wood structure. The aerogels retain structural anisotropy of natural wood, possessing specific surface areas up to 247m2/g, and exhibit reasonably high compressive yield strength of 1.2 MPa at 95% porosity, which is even higher than most of the cellulose-based aerogels. Figure 2 depicts schematically the steps involved in this Top-Down improved process.

Figure 2) Schematic illustration of the wood aerogel preparation procedure

Reprinted under Creative Commons Attribution 4.0 International license (Top-Down Approach Making Anisotropic Cellulose Aerogels as Universal Substrates for Multi-functionalization, Jonas Garemark, Xuan Yang, Xia Sheng, Ocean Cheung, Licheng Sun, Lars A. Berglund, and Yuanyuan Li, ACS Nano 2020 14 (6), 7111-7120, DOI: 10.1021/acsnano.0c01888 .

However, the limitation of this technique is that it results into highmoisture sensitivity of DMAc/LiCl for cell wall dissolution and unsatisfactory structural control of nano-cellulosic networks formation. To resolve this issue, ionic liquids offer a great promise for the formation of Nanofibrillar aerogels (The Preparation of LignocellulosicAerogels from Ionic Liquid Solutions, Cellulose II aerogels: a review). Ionic liquids have the ability to be designed to react with wood in a controllable manner. Therefore, incorporation of ionic liquid in the process would help in circumventing this difficulty and in the present work this approach was pursued.

Figure 3) Schematic of wood aerogels formation. The left-hand side illustrates the hierarchical structureof wood. Followed by the depiction of delignified wood, the ionic liquid penetration, cellulosic dissolution, and cellulosic precipitation. The final wood aerogel shows lumen space filled with nanofibrils networks.

Reprinted under Creative Commons Attribution 4.0 International license (Nanostructurally Controllable Strong Wood Aerogel toward Efficient Thermal Insulation, Jonas Garemark, Jesus E. Perea-Buceta, Daniel Rico del Cerro, Stephen Hall, Barbara Berke, IlkkaKilpeläinen, Lars A. Berglund, and Yuanyuan Li, ACS Applied Materials & Interfaces 2022 14 (21), 24697-24707, DOI: 10.1021/acsami.2c04584)

In the present work,a team of researchers from Sweden and Finland were able to produce a strong and high-performance thermal insulating wood aerogel with cellulosic nanofibril networks occupying the lumen space, which was achieved through wood cell wall dissolution and controlled precipitation in the lumen space, using an ionic liquid mixture consisting of a guanidinium phosphorus-based ionic liquid [MTBD]+[MMP].The representation of the formation of wood aerogels is schematically shown in Figure. 3. The obtained wood aerogel exhibits a distinctive structure with lumen filled with nanofibrils network. This novel structure displays specific surface areas up to 280 m2/g and high yield strengths >1.2 MPa.

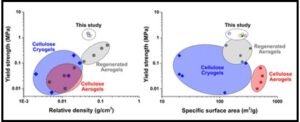

Figure 4- (Left side diagram) Yield strength against relative density and (Right side diagram) yield strength against Specific Surface Area (SSA) for cellulose cryogels (freeze-dried), cellulose aerogels (Critical point dried), regenerated aerogels (Critical point dried) and our wood aerogels (Critical point dried).

Reprinted under Creative Commons Attribution 4.0 International license (Nanostructurally Controllable Strong Wood Aerogel toward Efficient Thermal Insulation, Jonas Garemark, Jesus E. Perea-Buceta, Daniel Rico del Cerro, Stephen Hall, Barbara Berke, IlkkaKilpeläinen, Lars A. Berglund, and Yuanyuan Li, ACS Applied Materials & Interfaces 2022 14 (21), 24697-24707, DOI: 10.1021/acsami.2c04584).

The partially preserved cellulose orientation of the wood aerogel provides alignment of stiff fibrils, resulting in strength values that are impossible to attain with cellulose aerogels prepared by bottom-up technique, including anisotropic aerogel synthesized via directional freeze-casting (Mechanically strong fully biobased anisotropic cellulose aerogels). Figure 4 shows yield strength versus relative density of three types of cellulose-based aerogels prepared from (a) nanocellulose cryogels (nanocellulose substrates via cryogenic freezing and freeze-drying), (b) nanocellulose aerogels, and (c) regenerated cellulose aerogels. The wood-based aerogels in this work show greater yield strength as compared to that of regenerated cellulose with the same or even higher density. This is mainly due to the tendency to preserve the high degree of alignment of fibrils in the original native wood. It should be noted that the combination of high SSA and mechanical strength can be attributed to this unique dual mesoporous structure (Figure 4-Right side diagram).

Figure- 5(Upper diagram) Thermal conductivity of NW, DW, and 24 h IL treated wood aerogel from radial and axial direction. (Lower diagram) IR-camera measured temperatures over time comparing NW to 24 h IL treated wood aerogel placed on a hot plate of 70 °C.

Reprinted under Creative Commons Attribution 4.0 International license (Nanostructurally Controllable Strong Wood Aerogel toward Efficient Thermal Insulation, Jonas Garemark, Jesus E. Perea-Buceta, Daniel Rico del Cerro, Stephen Hall, Barbara Berke, IlkkaKilpeläinen, Lars A. Berglund, and Yuanyuan Li, ACS Applied Materials & Interfaces 2022 14 (21), 24697-24707, DOI: 10.1021/acsami.2c04584).

As shown in Figure 5- (Upper diagram)an apparent anisotropic thermal conductivity was observed for Native wood (NW) and Dilignified wood (DW) as well as Wood aerogel (Figure 6). The radial thermal conductivity was 0.088 and 0.051 W/mK for NW and DW, while axial conductivities were 0.134 and 0.090 W/mK, respectively. The lower values in DW are due to lower volume fraction (ρ*/ρs = 0.05) compared to NW (ρ*/ρs = 0.07), leading to decreased solid conduction in the cell wall. Cellulosic nanofibril network formation in the wood aerogel showed strong effects on the thermal conductivity. With a similar volume fraction of solids to that of DW (ρ*/ρs = 0.05), a value of 0.037 W/mK was observed in the radial direction and 0.057 W/mK was obtained in the axial for the wood aerogel. This is the lowest axial value reported so far in any of anisotropic wood aerogels (Highly Compressible, Anisotropic Aerogel with Aligned Cellulose Nanofibers).

To investigate the thermal insulation characteristics of the wood aerogel, temperature changes of upper surfaces over passage of time of samples, placed on hot plate of 70 °C were recorded using IR thermal camera Figure 5-(Lower diagram). With the axial direction parallel to heat flow, the temperature stabilized after 10 min at ∼47 °C for NW, while for wood aerogel the stabilization time was longer (15 min) and stabilized temperature was much lower (∼36 °C). Even after 60 min duration, the difference between the two materials remained almost the same, indicating the superior thermal insulation of wood aerogel. In the radial direction, both specimens showed stable temperature after 20 min and ∼26 °C for the aerogel (∼35 °C for NW).

The outstanding combination of high strength and remarkable thermal insulating properties surpasses other competitive cellulose-based thermal insulators. The unsophisticated and potentially scalable production method, the effectiveness to control the aerogel nanostructure, and the superb properties reported here contribute greatly toward sustainable high performing aerogels design strategy for advanced applications such as super thermal insulation.

About Author

Dr. Yashwant R. Mahajan was Technical Advisor at International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad, and also at ARC-I’s Centre for Knowledge Management of Nanoscience and Technology (CKMNT), Hyderabad. He obtained his Ph.D. degree in Physical Metallurgy in 1978 from Polytechnic Institute of Brooklyn, New York. Dr. Mahajan made major contributions in the areas of MMCs, advanced ceramics, and CMCs. Under his leadership, a number of ceramic- based technologies were developed and transferred to the industry. He has published more than 130+ technical papers in peer-reviewed journals and conference proceedings and holds 13 patents (including 2 US). Dr. Mahajan is a recipient of NRC Associateship of National Academy of Sciences, USA, the best metallurgist of the year award (IIM), MRSI Medal, MRSI-IISC superconductivity award, and VASVIK Medal. Dr Yashwant R Mahajan is also the Editorial Adviser to Nano Digest. Email: mahajan@nanodigest.in