From Carnegie Mellon University, Prof. Sheng Shen’s new 3D graphene-nanowire “sandwich” can enable various electronic systems to operate at low temperatures and with high efficiency.

As devices get smaller and more powerful, the risk of overheating and fatigue increases dramatically. Despite advances in cooling solutions, the interface between electronic chips and cooling systems remains a barrier to air travel due to the inherent strength of the materials.

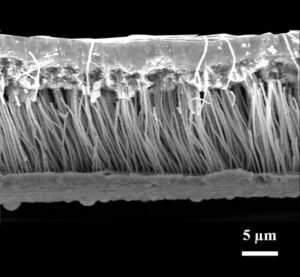

Sheng Shen, a professor of virtual engineering and a new window, has developed something flexible, powerful and very reliable to fill the gap well. “At first glance, our solution looks like any copper film, but under the microscope, the innovation of our material becomes clear,” said Lin Jing, Ph.D. student. explained.

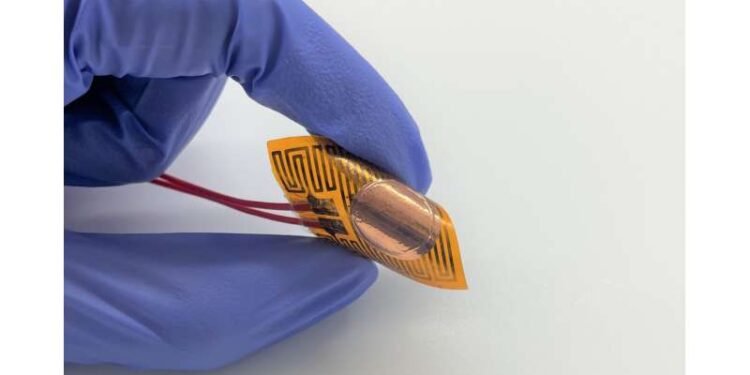

The device (New 3D graphene-nanowire “sandwich”), which consists of two thin copper films with a network of copper nanowires with graphene between them, is very friendly.

Rui Cheng, a postdoctoral researcher in Shen’s laboratory, said, “Other nanowires need to be grown in conditions where heat is generated to expand, so the entrance threshold and their cost are high.” “Our film is not based on any fruit; it is a self-supporting film that can be cut to any size or shape to fill the gap between different electrical components.

The ‘sandwich’ is made of Shen’s ‘super solder‘, a thermal transfer material (TIM) that can be used in the same way as the commercial ones, but with double the temperature of the TIM modern now.

By covering the “super-welder” with graphene, Shen’s team improved its heat transport ability and prevented the risk of oxidation, resulting in a longer life. “Sandwich”, compared to thermal pastes / adhesives currently on the market, can reduce heat resistance by more than 90% in the same size.

With its high speed conversion, “Sandwich” can make a variety of applications in flexible electronics and microelectronics, including flexible LEDs and lasers for lighting and displays, wearable sensors for communication , electronic equipment for health monitoring and imaging, and soft. plastic machine. Going forward, Shen’s team will explore ways to increase the material’s production level and reduce its cost, while continuing to look for ways to improve it.

“We’re very excited about the potential this thing has,” Shen said. “We believe that a wide variety of electronic systems can benefit by allowing them to operate at low temperatures and with high efficiency.”