Researchers have shown a new material (New silicone nanowires) that processes heat 150% more efficiently than conventional materials used in advanced chip technologies.

The device – an ultra-thin silicon nanowire – can produce smaller, faster microelectronics with heat transfer efficiency that surpasses existing technologies. Microchip-powered electronic devices that efficiently dissipate heat can also consume less energy – an improvement that will help reduce the energy consumption produced by burning carbon-rich fossil fuels, which contribute to global warming.

“By overcoming the natural limitations of silicon in its ability to transfer heat, our findings (New silicone nanowires) pose an obstacle in microchip technology,” said Junqiao Wu, a research scientist at the Physical Review Letters. reports new device. Wu is a faculty scientist in the Materials Science Division and a Professor of Materials Science and Engineering at UC Berkeley.

Slow heat flow through silicon

Our electronics are relatively inexpensive because silicon – the material of choice for computer chips – is cheap and abundant. But while silicon is a good conductor of electricity, it is not a good conductor of heat when it is short in small dimensions – and when it comes to fast calculations, it is a big problem for small microchips. Inside each microchip are tens of billions of silicon transistors that control the flow of electrons inside and outside the memory cells and encode the data fragments as ones and zeros, which is the binary language of the computer. Electric currents flow between these busy transistors and generate the inevitable heat.

Heat naturally flows from a hot object to a cold one. But heat flow is difficult in silicon.

Silicon in its natural form (New silicone nanowires) is composed of three different isotopes – chemical elemental forms, which have the same number of protons in their nuclei, but different numbers of neutrons (ie different masses). About 92% of silicon consists of the silicon-28 isotope, which has 14 protons and 14 neutrons; about 5% is silicon-29 weighing 14 protons and 15 neutrons; and only 3% is silicon-30, a relatively heavyweight of 14 protons and 16 neutrons, explained co-author Joel Ager, who holds the title of Chief Scientist in the Materials Science Division at Berkeley Lab and an adjunct professor of materials science and engineering. UC Berkeley.

Like phonons, the waves of atomic vibration that transfer heat move in the crystal structure of silicon and change direction as they collide with silicon-29 or silicon-30, from which different masses of atoms “confuse” the phonons they have weakened.

“Phonons eventually got the idea and found their way to the cold end to cool the (New silicone nanowires) silicon material,” but this indirect path allows waste to accumulate, which in turn slows down your computer, like Ager. A big step towards faster and denser microelectronics

For decades, scientists have believed that chips made of pure silicon-28 can overcome the limitations of the thermal conductivity of silicon, and therefore improve the processing speed of smaller, denser microelectronics.

But isotope purification of silicon requires extreme levels of energy, which can provide very few facilities – and even fewer isotope market preparation specialists – according to Ager.

Fortunately, an early 21st-century international project allowed Ager and leading semiconductor materials expert Eugene Haller to extract silicon tetrafluoride – the starting material for isotopically pure silicon – from a former Soviet-era isotope plant. (Haller founded the Berkeley Lab Funded Electronic Materials Program in 1984 and is a senior faculty scientist in the Materials Sciences Division at Berkeley Lab and a professor of materials science and mineral engineering at UC Berkeley. He died in 2018.)

This led to a series of breakthrough experiments, including a 2006 study published in Nature, in which Ager and Haller converted silicon-28 into a crystal, which they used to demonstrate quantum memory storage. information such as quantum bits or qubits, units of data stored simultaneously as one and zero in the spin of the electron.

Subsequently, semiconductor thin films and crystals made from Ager’s and Haller’s silicon isotope material have been shown to have 10% higher thermal conductivity than natural silicon – an improvement, but from a computer point of view, this is probably not enough to justify spending thousands. times more money to make a computer from isotopically pure silicon, Ager said.

But Ager knows that silicon isotope materials (New silicone nanowires) are of scientific interest outside of quantum calculations. He, therefore, keeps the rest in a safe place in a Berkeley laboratory when other scientists need it because few have the means to produce or even buy isotopically pure silicon, he says.

The road to silicon-28 heatsink technology

About three years ago, Wu and his graduate student Penghong Ci tried to come up with new ways to improve the heat transfer rate of silicon chips.

One strategy for increasing the efficiency of transistors involves using a type of nanowire called the Gate-All-Around Field Effect Transistor. Silicon nanowires are placed in these devices, which conduct electricity and generate heat at the same time, Wu explained. “And if the heat generated is not removed immediately, the appliance will stop working, similar to a fire alarm that will sound in a tall building without an evacuation card,” he said. But heat transfer is even worse with silicon nanowires because their rough surfaces – chemical processing reports – scatter or “confuse” phonons, he explained.

“And then one day we thought, ‘What happens when we make a nanowire from isotopically pure silicon-28?’ ” Wu said.

Silicon isotopes are not something that can be easily bought on the open market, and Ager reportedly stored a few crystals of silicon isotopes in a Berkeley lab – not many, but enough to share, “if someone has a good idea of how” you can to use, ”said Ager. “And Junqiao’s new study is an example of that.”

Surprisingly large revelation with nano-tests

“We were very lucky that Joel happened to have isotopically enriched silicon material ready for use in the study,” Wu said.

Using Ager’s silicon isotope materials, the Wu team tested the thermal conductivity of most 1-millimeter silicon 28 crystals compared to natural silicon – and their experiment again showed what Ager and his colleagues discovered years ago – that silicon -28 processes heat. . Only 10% better than natural silicon.

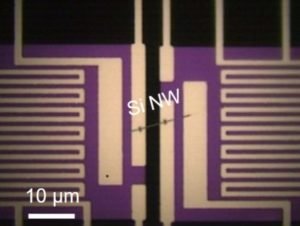

Now for the nano test. Using a technique called electroless etching, Ci created natural silicon and silicon -28 nanowires that were only 90 nanometers (billionths of a meter) in diameter – about a thousand times thinner than one strand of hair.

To measure the thermal conductivity, Ci hung each nanowire between two micro heating pads equipped with platinum electrodes and thermometers, and then applied an electric current to the electrode to generate heat from one pad flowing to the other pad through the nanowire. “We expect to see only an incremental advantage – such as 20% – when using isotopically pure nanofiber heat conduction material,” Wu said.

But the Ci measurement surprised them all. Si-28 nanowires do not conduct heat by 10% or even 20%, but 150% better than natural silicon nanowires with the same diameter and surface roughness.

It was against everything she expected to see, according to Wu. The hard surface of the nanowire often weakens the phonons. So, what happened?

Higher-resolution TEM (Transmission Electron Microscopy) images of Matthew R. Jones and Muhua Sun at Rice University revealed the first hint: a glass-like layer of silica on top of the silicon nanofiber-28.

Computational simulation experiments at the University of Massachusetts Amherst led by Zlatan Aksamiya, a leading expert on the thermal conductivity of nano tracks, have shown that a lack of isotope “defects” – silicon -29 and silicon -30 – prevent phonons from escaping from a surface where a layer of silica can significantly weaken. This in turn keeps the phonons in orbit in the direction of heat flow – and is, therefore, less “confusing” – in the “core” of silicon nanowire -28. (Aksamiya is currently an Associate Professor of Materials Science and Engineering at the University of Utah.)

“It simply came to our notice then. “Finding that the two different phonon-blocking mechanisms – surface versus isotopes, which were once thought to be independent – now work synergistically in our hot run is shocking but also satisfying,” Wu said.

“Junqiao and the team have discovered a new physical phenomenon,” Ager said. “It’s a real victory for curiosity-driven science. It’s very exciting.” Wu said the team planned to take their findings to the next level: by exploring how to “control the thermal conductivity of these materials instead of just measuring.”

Researchers from Rice University; University of Massachusetts-Amherst; Shenzhen University and Tsinghua University participated in the study.

This work (New silicone nanowires) was supported by the DOE Office of Science.