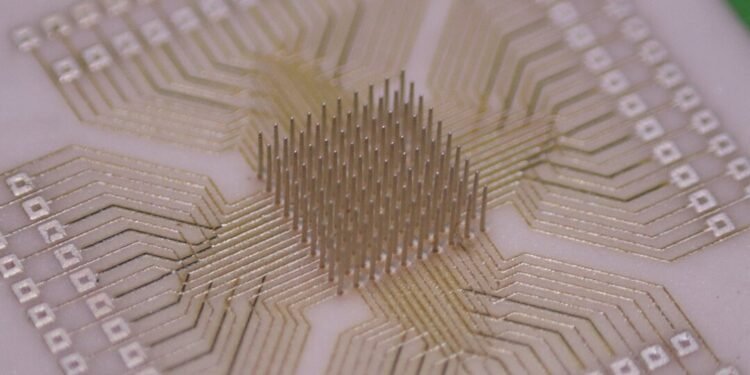

Carnegie Mellon University researchers pioneered the CMU Array, a new type of microelectrode for brain-computer interface platforms. It has the potential to change the way doctors can treat neurological diseases. A dense microelectrode array (MEA), which is (Newest micro fabrication technique in 3D printing) 3D printed at the nanoscale, is highly customizable.

This means that one day, patients with epilepsy or disability due to stroke may benefit from personalized treatment for their individual needs. The collaboration combines the expertise of Rahul Panat, associate professor of mechanical engineering, and Eric Yttri, associate professor of physical sciences.

The team applied the latest microfabrication technique, Aerosol Jet 3D printing, to create die-cut key design blocks and other brain-computer interface (BCI) dies.

The results were published in Science Advances.

“Aerosol jet 3D printing offers three main advantages,” Panat explained. “Users can customize their MEA to meet specific needs; MEA can work three-dimensionally in the brain; and the density of MEA is increased and therefore stronger.”

MEA-based BCI connects neurons in the brain with external electronics to monitor or stimulate brain activity. They are often used in applications such as neuroprosthetic devices, prosthetic limbs, and visual aids that carry information from the brain to the affected limb.

BCI also has potential applications in the treatment of neurological disorders such as epilepsy, depression, and anxiety disorders. However, existing tools have limitations. There are two popular types of BCI devices.

The oldest MEA is the Utah Network, which was developed at the University of Utah and licensed in 1993. The silicon-based network uses tiny pin fields, or rods, that can be inserted directly into the brain to detect the electrical output from neurons at the end of each pin.

Another type is the Michigan board, which is printed on a flat, hard piece of silicon. It reads the electrons as they flow through the page. Due to design limitations, these two systems can only be recorded on a two-dimensional plane. This means that they cannot be customized to meet the needs of each patient or application.

The most important part of MEA is its three-dimensional sampling capability, which is limited by the density of microelectrodes in the array and the ability to set these bases wherever one wants to find.

Modern MEA fabrication techniques have made dramatic advances in the density of these microelectrode devices. Adding a third dimension greatly increases the visibility of arrays. In addition, MEAs that are tailor-made for each specific application allow for accurate and reliable readings.

The researchers’ CMU Array is the densest BCI, about an order of magnitude denser than the BCI and Utah Array.

Better AMEs are needed. These MEAs are used to control computer-generated behavior or complex hand movements that defy the limits of current technology. More advanced applications require MEAs that are customized and have higher reliability than the current ones.

“Within a few days, we can create a precision medicine device that is tailored to the needs of the patient or the researcher,” says Yttri, who co-led the study. In addition, as technologies such as visual cortex stimulation and hand control are used successfully by the public, the ability to program the control system in the brain may open the way for major advances in the field.

Panat predicts it will take five years to see human trials, and even longer to see commercial use. The team is excited to share this successful method with other researchers in the field to begin testing different types of applications.

A patent on the operation and production process of the CMU Array is pending. The next step, Panat says, is to work with the National Institutes of Health (NIH) and other commercial partners to get these (Newest micro fabrication technique in 3D printing) results to other laboratories as quickly as possible and seek funding that will improve the skills and This technology is marketed.