Putting the soda bottle or disposables in the recycling center does not guarantee that it will be turned into something new. Scientists at Rice University are trying to solve this problem by making the process more effective, Plastic waste disposal services guarantee benefits.

The amount of plastic waste produced worldwide has doubled in the past two decades – and plastic production is expected to triple by 2050 – which ends up in landfills grass, hot or unhealthy, according to the Organization for Co-operation and Development. Some estimates show that only 5% are actually reformed.

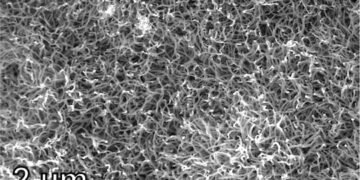

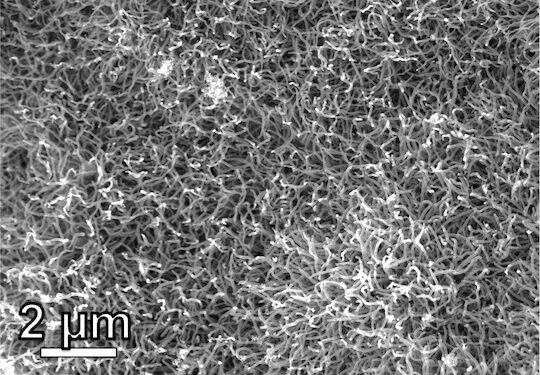

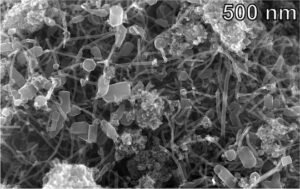

“Plastic waste is not recycled because it is too expensive to wash, process and melt the plastic into something that can be used by industry,” said Kevin Wyss, a Rice graduate student and author. in Advanced Materials that describes how he and his colleagues and chemist James Tour from the lab used their Joule flash heating method to change plastic into useful carbon nanotubes and hybrid nanomaterials.

“We were able to create a hybrid carbon nanomaterial that outperformed both graphene and carbon nanotubes on the market,” Wyss said.

Graphene, carbon nanotubes, and other carbon nanomaterials are strong and chemically strong, have low density and large surface area, and have conductivity and broadband electromagnetic absorption power. This makes them useful in many industrial, medical and electronic applications such as composites, coatings, sensors, electrochemical energy storage and others.

“What’s really exciting about our results so far is that we can make these carbon nanotubes with a piece of graphene attached to the ends,” Wyss said. “You can think of the structure of this new hybrid nanomaterial as similar to beans or lollipops. These are usually difficult to make, and the fact that we can use scrap plastic to make them is special.

The design of a new hybrid carbon nanomaterial is for improving its performance.

“Let’s say I’m trying to pull the yarn out of a sweater,” Wyss said. “If the fiber is straight and flat, sometimes it can come out very quickly and damage the fabric. It’s the same with carbon nanotubes; having a lot of those graphenes attached to the ends helps make they are more difficult to remove, thus strengthening the composition.

“You can also think about it this way: If you have a splinter, it’s easy to pull. But if you’re going through something that’s complicated end to end, like a hook, it getting harder to pull.” he added.

Plastic, which does not need to be processed or washed like traditional recycling, “glows” at temperatures above 3,100 Kelvin (about 5,120 degrees Fahrenheit). “All we do is put the material into a small confetti-sized piece, add a bit of metal, and mix with a small amount of different carbon – let’s say dirt – for conductivity”, Wyss said.

“Recycling plastic costs more than just making new plastic,” he added. “There are few economic incentives to recycle plastic. That’s why we turn to upcycling, or turning low-level waste into something with a high monetary value or benefit. If we can recycle plastic waste into something more useful, then people can make money by being responsible for how they deal with discarded plastics.

A life-cycle study of the production process showed that the Joule lamp is more environmentally friendly than the current nanotube production process.

“Compared to the commercial process of producing carbon nanotubes that is currently used, ours uses about 90% less energy and emits 90-94% less carbon dioxide,” Wyss said.