From the time of first use, the new lithium-ion battery degrades. After a few hundred charging cycles, you will notice that the battery in your cell phone, laptop or electric car wears out quickly. Eventually, he stopped holding debt altogether.

Researchers at the University of Chicago’s Pritzker School of Molecular Engineering (PME) have used a combination of advanced electron microscopy and computer processing to understand, at the atomic level, exactly what happens when lithium ion decays. Their research points to a way to create long-lasting lithium-ion batteries – focusing on an often overlooked structural component, the carbon binder (CBD) sector.

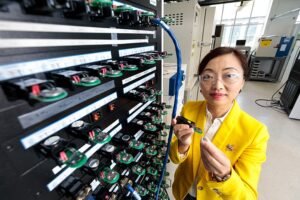

“To meet many of the world’s energy security and transition challenges in the coming decades, we will continue to develop and improve batteries,” said the professor. Y. Shirley Meng, who led the research, published in the journal Joule. “This project is a step forward in efficient battery technology.”

The length of the loan is limited

The widespread commercialization of lithium-ion batteries in the late 20th century played a role in the advent of lightweight electronics. Lithium is the lightest metal and has high energy and mass. When a lithium-ion battery is charged, lithium ions move from the positively charged cathode to the negatively charged anode. To release energy, these ions move from the anode back to the cathode. During charging, the active cathode and anode materials expand and contract, accumulating “debris” and other physical damage.

Over time, this makes lithium-ion batteries ineffective. Researchers have previously described cracks and particle damage occurring in the thin electrodes of lithium-ion batteries. However, stronger, more powerful electrodes are being developed for larger batteries – in applications including electric cars, trucks and airplanes.

“The thickness of the solid electrode is very different from that of the thin electrode,” said scientist Minghao Zhang of the University of California, San Diego, who was the first author of the new paper. “The damage is actually worse with the high power electrodes, which are struggling for pitch.”

Zhang said it is also more difficult to produce larger electrodes. The tools that used to study thin electrodes could not handle the construction of large and expensive materials.

Integrating microscopy and structure

In the new work, Meng, Zhang and colleagues at Thermo Fisher Scientific turned to plasma-enhanced ion-beam scanning electron microscopy (PFIB-SEM) to observe the changes occurring inside large lithium-ion batteries. PFIB-SEM uses a focused beam of ions and electrons to collect high-resolution images of the three-dimensional structure of objects.

The researchers used imaging techniques to collect data on new cathodes and those that had been damaged and destroyed 15 times. Using data from electron microscopy experiments, the team built a computer model showing the battery’s degradation process.

“This combination of experimental nanoscale resolution and data processing is what allowed us to determine how the cathode degrades,” said PME postdoctoral researcher Mehdi Chouchane, first author of the paper. “Without that kind of display, it’s going to be hard to show what’s going on.”

The researchers found that the changes between the battery areas supported many structural changes. Electrolyte corrosion occurs frequently in the thin layer on the surface of the cathode. As a result, this layer is resistant to cold, which caused the lower layer to expand and expand more than other parts of the cathode, causing rapid damage.

The model also shows the importance of CBD – a porous grid of fluoropolymer and carbon fiber that connects the active elements of the electrode and helps conduct electricity from the battery. Previous research has not clarified how CBD degrades during battery use, but the new work shows that the weakness of the contact between CBD and the active material of the cathode directly reduces the performance of lithium-ion batteries.

“This change is more obvious than the explosion of active materials, which many researchers have focused on in the past,” said Zhang. The battery of the future

With their cathode models, Meng’s team investigated how modifications to the electrode’s design could affect its degradation. They showed that changing the network structure of the CBD can help prevent the contact between the CBD and the active material from worsening, thus extending the life of the battery – a hypothesis engineers can now follow through research the body. . The team is now using the same method to study even larger cathodes, as well as to develop additional models for how to reduce electrode damage.

As Dr. According to Zhao Liu, general manager of battery market development at Thermo Fisher Scientific, who contributed to the research, “This study creates a method for developing electrodes to improve battery performance in the future.”