A team of researchers led by Professor Anderson HC Shum of the Department of Mechanical Engineering at the University of Hong Kong (HKU) and Professor Thomas P. Russell of Lawrence Berkeley National Laboratory have developed an all-water robotic (Researchers pioneer biocompatible all-water “Aquabots”) system that overcomes these obstacles. Thank you. as the scientific revolution progressed.

Soft robots have made tremendous progress in recent years. Micro-scale soft robotics designed to navigate difficult and perform biological functions in the human body may have profound medical applications such as surgery, prosthetics and pain relief.

Currently, the intrinsic functionality of bio-based soft robots is based on elastomeric materials such as silica gel, which requires the introduction of large amounts of material into the necessary structure. They are very limited in their degree of deformity compared to their counterparts.

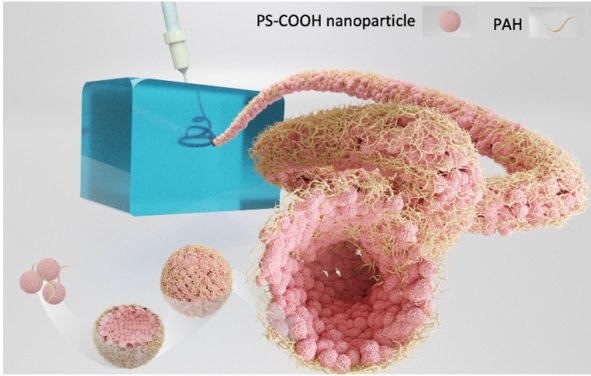

The researchers created (Researchers pioneer biocompatible all-water “Aquabots”) the “Aquabots”, a new class of soft water robots that are the most liquid. Vascular microscale structures are printed in all-liquid 3D printing technology with an interfacial assembly of a second liquid system, which helps to separate two different liquid polymers.

The study is currently being published in ACS NANO. Aquabot with its multi-dimensional structure and micrometric size is shown in the supplemental cover of the Journal.

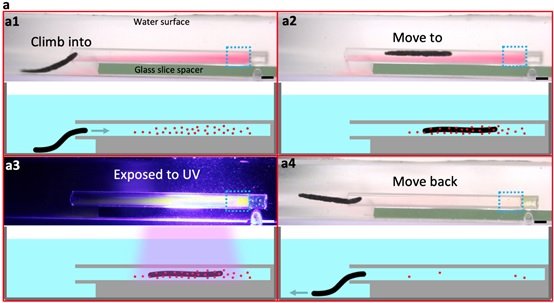

“Our idea is to combine the materials in a way that will make the interface and structure retain the shape of the liquid. External forces such as magnetic forces control the shape and form an arbitrary shape, or get it using all-liquid 3D printing,” said Professors Shum and Russell.

Although the model can be created using all-water 3D printing, Aquabots many building blocks measure in several micrometers and exceed the printing resolution. They assemble themselves through the division of the liquid system, where one mixture of one gives two liquids. This helps to create building blocks of Aquabots that overcome the obstacles of deformation.

The skin of these structures works quickly, which is important for various medical applications.

“Compartmentalized membranes work very well in simple ways, for example, by combining enzymes, catalytic nanoparticles and magnetic nanoparticles that provide a mild magnetic response,” said Professor Russell.

Functionality favors efficient catalysis in cascade reactions. In the study, the research team showed that Aquabots work with the enzyme glucose oxidase that can trigger a stress reaction.

Aquabots are fluid in their movements. They have a soft tactile appearance and the ability to carry active substances (for example, drugs, stimulants, enzymes, etc.) and control substances (for example magnetic nanoparticles) in structures and on the skin him. They can easily cover the drug through their inspired parts and go to a narrow and dangerous place for drug delivery in the human body. Aquaboats can also change shape to fit different parts and hold things. Defects have been a challenge for scientists and medical professionals, since sometimes robots get stuck in the middle before reaching the desired areas when administering medicine.

“Robots are completely liquid, with water inside and outside. They work quickly to be flexible, so it is not difficult to imagine a large application of bio- their mud, that is in the body, where such things can be useful,” Prof. Russell said. “Thus, Aquabots create new opportunities to recreate bio-inspired objects and features, such as functional strength in the field.” Professor Russell added.

Researchers are optimistic that Aquabots, which have been shown to be compatible, multicompartmental and multifunctional, can open the way for the advancement of global biomedical applications, including medical micromanipulation, targeted delivery, tissue engineering and biomimetics.

The research team is looking at introducing biocompatible and biodegradable hydrogels into the Aquabots assembly. A complete shape change can be achieved due to the flexible nature of hydrogels.

“In our future work, it will be interesting to explore more about the functionality of the Aquabot platform and the structure and chemical reactions shown in the paper,” said Professor Shum.

“For example, we are trying to make Aquabots conduct electricity by combining water-soluble conductive polymers. It will be interesting to combine this with other microfluidic and robotic methods for new applications, such as the construction of biological electrical circuits and rational selection channels for ions. He added.