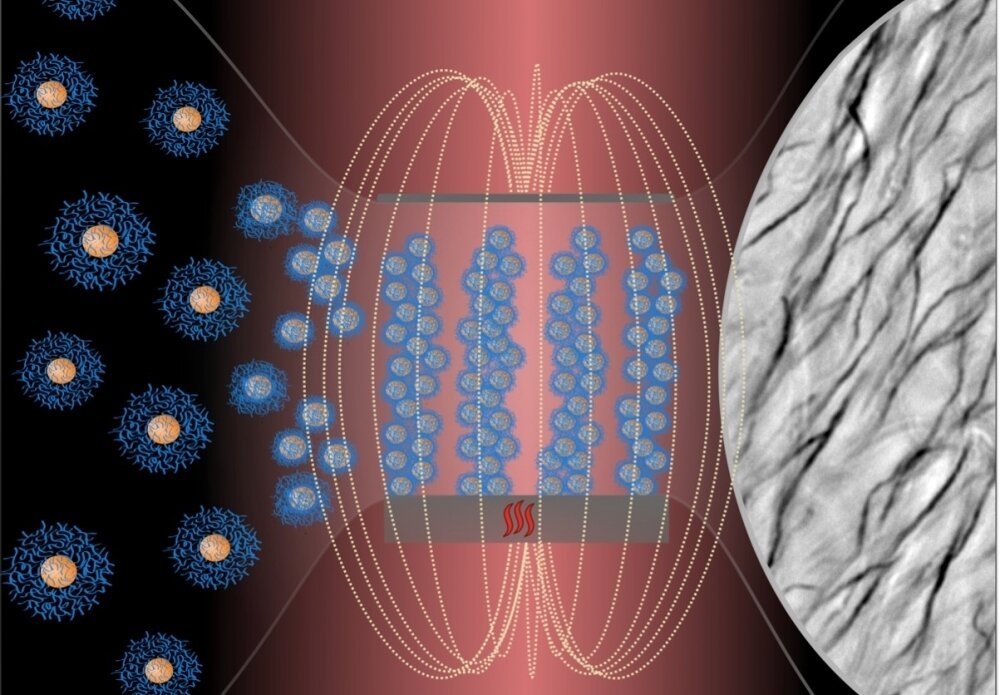

Filaments made of polymer-coated iron oxide nanoparticles are obtained by exposing the material to a magnetic field under controlled temperature. The applications are myriad and include transporting substances into cells or directing fluids. Credit: researchers’ archive.

Researchers at the University of Campinas’s Chemistry Institute (IQ-UNICAMP) in the state of São Paulo, Brazil, have developed a template-free technique to fabricate cilia of different sizes that mimic biological functions and have multiple applications, from directing fluids in microchannels to loading material into a cell, for example. The highly flexible cilia are based on polymer-coated iron oxide nanoparticles, and their motion can be controlled by a magnet.

In nature, cilia are microscopic hairlike structures found in large numbers on the surface of certain cells, causing currents in the surrounding fluid or, in some protozoans and other small organisms, providing propulsion.

To fabricate the elongated nanostructures without using a template, Watson Loh and postdoctoral fellow Aline Grein-Iankovski coated particles of iron oxide (γ-Fe2O3, known as maghemite) with a layer of a polymer containing thermoresponsive phosphonic acid groups and custom-synthesized by a specialized company. The technique leverages the binding affinity of phosphonic acid groups to metal oxide surfaces, fabricating the cilia by means of temperature control and use of a magnetic field.

“The materials don’t bind at room temperature or thereabouts, and form a clump without the stimulus of a magnetic field,” Loh explained. “It’s the effect of the magnetic field that gives them the elongated shape of a cilium.”

Grein-Iankovski started with stable particles in solution and had the idea of obtaining the cilia during an attempt to aggregate the material. “I was preparing loose elongated filaments in solution and thought about changing the direction field,” she recalled. “Instead of orienting them parallel to the glass slide, I placed them in a perpendicular position and found they then tended to migrate to the surface of the glass. I realized that if I forced them to stick to the glass, I could obtain a different type of material that wouldn’t be loose: its movement would be ordered and collaborative.”

The thermoresponsive polymer binds to the surface of the nanoparticles and organizes them into elongated filaments when the mixture is heated and exposed to a magnetic field. The transition occurs at a biologically compatible temperature (around 37 °C). The resulting magnetic cilia are “remarkably flexible”, she added. By increasing the concentration of the nanoparticles, their length can be varied from 10 to 100 microns. One micron (μm) is a millionth of a meter.

“The advantage of not using a template is not being subject to the limitations of this method, such as size, for example,” Grein-Inakovski explained. “In this case, to produce very small cilia we would have to create templates with microscopic holes, which would be extremely laborious. Adjustments to coat density and cilium size would require new templates. A different template has to be used for each end-product thickness. Furthermore, using a template adds another stage to the production of cilia, which is the fabrication of the template itself.”

Grein-Iankovski is the lead author of an article published in The Journal of Physical Chemistry C on the invention, which was part of a Thematic Project supported by FAPESP, with Loh as principal investigator.

“The Thematic Project involves four groups who are investigating how molecules and particles are organized at the colloidal level, meaning at the level of very small structures. Our approach is to try to find ways of controlling these molecules so that they aggregate in response to an external stimulus, giving rise to different shapes with a range of different uses,” Loh said.

Reversibility

After the magnetic field is removed, the material remains aggregated for at least 24 hours. It then disaggregates at a speed that depends on the temperature at which it was prepared. “The higher the temperature, the more intense the effect and the longer it remains aggregated outside the magnetic field,” Grein-Iankovski said.

According to Loh, the reversibility of the material is a positive point. “In our view, being able to organize and disorganize the material, to ‘switch the system on and off’, is an advantage,” Loh said. “We can adjust the temperature, how long it remains aggregated, cilium length, and coat density. We can customize the material for many different types of use, organize it and shape it for specific purposes. I believe the potential applications are countless, from biological to physical uses, including materials science applications.”

Another major advantage, Grein-Iankovski added, is the possibility of manipulating the material externally, where the tool used to do so is not inside the system. “The filaments can be used to homogenize and move particles in a fluid microsystem, in microchannels, simply by approaching a magnet from the outside. They can be made to direct fluid in this way, for example.”

The cilia can also be used in sensors, in which the particles respond to stimuli from a molecule, or to feed microscopic living organisms. “Ultimately it’s possible to feed a microorganism or cell with loose cilia, which cross the cell membrane under certain conditions. They can be made to enter a cell, and a magnetic field is applied to manipulate their motion inside the cell,” Loh said.

For more than ten years, Loh has collaborated with Jean-François Berret at Paris Diderot University (Paris 7, France) in research on the same family of polymers to obtain elongated materials for use in the biomedical field. “We’re pursuing other partnerships to explore other possible uses of the cilia,” he said.

The scientists now plan to include a chemical additive in the nanostructures that will bind the particles chemically, obtaining cilia with a higher mechanical strength that remain functional for longer when not exposed to a magnetic field, if this is desirable.