A research group from Skoltech, Aalto University and the Kurnakov Institute has recently produced a novel, diverse and simple method for carbon nanotubes for the production of carbon nanotube and polymer nanocomposites. This process is reported in Carbon and involves making briquettes – large packages of carbon nanotube powders. Nanocomposites made of briquettes work as well as those made from expensive master batches, which are also polymer-specific, that is small, Small nanoparticles have a surprising effect.

“We believe that the use of large carbon nanotube briquettes can support the development of the carbon nanotube composite industry. This method is cheap and applies to different types of polymer matrices, without sacrificing any of the electrical and thermal properties of the final material,” said the leader of the study, Skoltech PhD student Hassaan Butt said.

In the past decades, carbon nanotubes have been thoroughly investigated by researchers in academia and industry due to their unique combination of electricity, light and materials. Currently, polymer-based nanocomposites have become the largest application of carbon nanotubes and are approaching full integration in daily life. It is easy to see why: a small amount of nanotubes added to the polymer gives the material clearly new properties, such as electrical conductivity and piezoresistivity, as well as improving its properties and properties.

Carbon studies recently started as an attempt to solve the challenge of obtaining a sufficient dispersion of carbon nanotubes in a host polymer to obtain a good composite. To achieve this, Skoltech researchers and their collaborators at the Kurnakov Institute studied the process of rapid rapid diffusion (RESS) of nanotubes, which leads to deagglomeration them. However, it did not provide any progress on the ultimate characteristics of polymer nanocomposites. The team decided to explore what this means from a different angle.

The study of the author and one of the main contributors, Skoltech PhD student Ilya Novikov, explained: not improve the composition of the properties, we think, why do it. we do back and compress mouth and powders instead. What if compression doesn’t affect property performance? The reason this would be so exciting, he added, is that higher density means greater efficiency and less manufacturing safety risk due to unwanted aerosolization of nanotubes.

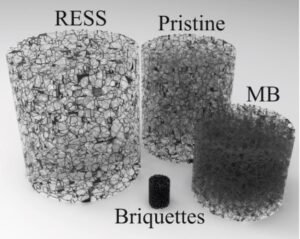

In this way, the authors continued with different work processes, the study focused on the effect of carbon nanotube powder density, or the degree of preconsolidation, on the performance characteristics of composition. To increase the density, the researchers pneumatically compressed a powder of virgin nanotubes. After that, the group studied the properties of epoxy nanocomposites made from four types of carbon nanotube powders: expanded (RESS), virgin, compressed (briquette shaped) and commercial masterbatches – the last one is nanotubes also predispersed in the polymer from the manufacturer. Unexpectedly, all the studied properties, including morphology, electrical conductivity, thermal conductivity, and stability, were found to be the same, despite the large density of nanotubes.

“Surprisingly, we found that the electrical behavior is actually the same that all the compounds got. Then we reveal the same for the thermal properties. We note that this is a similar spatial distribution of nanotubes in epoxy. The most remarkable thing here is that the high-value, specific material of the masterbatch business turns out to be the same as our briquettes. Also, on the other hand, they are easier and safer to handle, compared to the virgin and spread powder,” said the research leader of the study, Professor Skoltech Albert Nasibulin.

Carbon nanotubes are such an ultralight material that emissions and safety risks related to workers are the main issues for the production of nanocomposites. It can be avoided, the authors suggest, by using briquettes, which is thus a cheap, simple and possible solution to facilitate the use of carbon nanotubes in educational institutions in the industrial sector, which is the result of an effort to overcome various problems.