A piece of the ruthenium atom in the eye of copper nanowires could be a step toward a revolution in the global ammonia industry, which (The new process aims to extract ammonia from dirty water) will also help the environment.

Collaborators Rice University George R. Brown School of Engineering, Arizona State University, and Pacific Northwest National Laboratory have developed a high-performance catalyst that can extract ammonia and solid ammonia – or fertilizers – from low nitrate levels, which are widely used in industry, with almost 100% efficiency. wastewater and contaminated. groundwater.

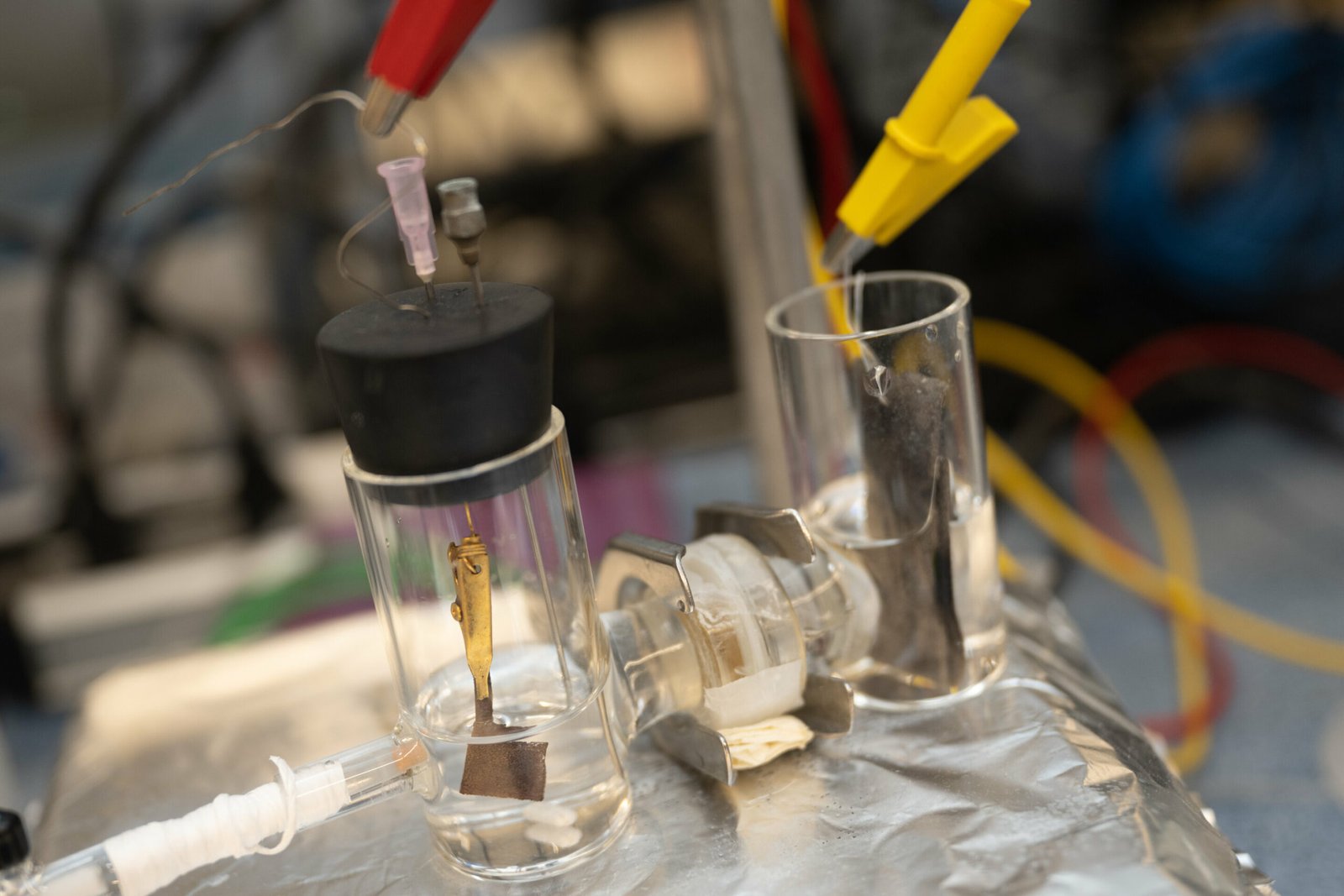

A study led by chemical and biomolecular engineer Rice Haotian Wang found that this process converts 2,000 ppm nitrate levels to ammonia, followed by an efficient gas removal process to collect the ammonia product. The remaining nitrogen concentrations after these treatments can be reduced to “drinking” levels as defined by the World Health Organization.

“We have completed the complete water denitrification (The new process aims to extract ammonia from dirty water) process,” said graduate student Feng-Yang Chen. “By greater treatment of water from other pollutants, we can turn industrial waste into drinking water.”

Chen is one of the top three authors of an article that appears on the subject (The new process aims to extract ammonia from dirty water) of Nature Nanotechnology.

The study shows a good alternative to efficient processes for an industry that relies on an energy-intensive process to produce more than 170 million tons of ammonia per year.

Researchers from previous studies know that ruthenium atoms are experts in catalyzing nitrate-rich water. Their reversal is that it combines with copper, which inhibits the evolutionary reaction of hydrogen, a method of producing hydrogen from water, which is a side effect in this case. “We know that ruthenium is a good candidate for nitrate reduction, but we also know that there is a big problem that it can easily trigger a competitive reaction, that is, the evolution of hydrogen,” Chen said. “If we use electricity, a lot of electrons go into hydrogen, not the product we want.”

“We have borrowed a concept from other fields, such as carbon dioxide reduction, which uses copper to suppress hydrogen evolution,” Wang added. “Then we had to find a way to organically combine ruthenium and copper. It turned out that the best thing was to disperse one of the ruthenium atoms in the copper matrix.”

The team used density theory calculations to explain why ruthenium atoms facilitate the chemical pathway, which combines nitrates and ammonia, according to co-author Christopher Muhiche, an associate professor of chemical engineering in Arizona.

“If only ruthenium were present, water would interfere,” Muhich said. “If there’s only copper, there’s not enough water to produce hydrogen atoms. But in a place with ruthenium, water also can’t compete and supplies enough hydrogen without removing nitrate reaction sites.”

The process works at room temperature and under ambient pressure, and what researchers call an “industrial” reduction in nitrate flow by 1 ampere per square centimeter, which is the amount of electricity needed to increase the rate of catalysis. According to Chen, this needs to be delivered quickly. “I think it has great potential, but it doesn’t matter because it has been difficult for previous studies to achieve such a good current density while maintaining a good selection of products, especially at low nitrate concentrations,” he said. “But we’ll show it now. I’m sure we have opportunities to push this process through industrial applications, especially since it doesn’t require a lot of infrastructures.”

The main advantage of the process is the reduction of carbon dioxide emissions from traditional industrial ammonia production. That’s not enough, it represents 1.4% of the world’s annual emissions, scientists said.

“While we understand that converting nitrate waste to ammonia cannot completely replace the existing ammonia industry in the short term, we believe this process can make a significant contribution to decentralized ammonia production, especially in areas with high nitrate sources,” said Wang.