Graphene and nanomaterials have been touted as wonder materials, and they are proving invaluable in all sorts of applications, such as in the automotive and aerospace industries, where heavy metals are replaced with lighter but equally strong composite materials. Nanomaterial quality therefore matters a great deal, but standardization and quality checking have eluded the industry.

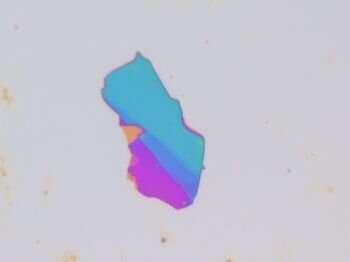

The Sussex team have developed a technique that gives detailed information about the size and thickness of graphene particles. It uses a non-destructive, laser-based method for looking at the particles as a whole, and lets them quickly build a detailed picture of the distribution of particles in a given material. Their paper, “Raman Metrics for Molybdenum Disulfide and Graphene Enable Statistical Mapping of Nanosheet Populations,” is published in the journal Chemistry of Materials.

Dr. Matt Large, who led the discovery in the School of Mathematical and Physical Sciences at the University of Sussex, said:

“Standards for measurement are a really critical underpinning of modern economies. It really comes down to one simple question; how do you know you got what you paid for? At the moment the graphene industry is a bit of a wild frontier; it’s very difficult to compare different products because there is no agreed way of measuring them. That’s where studies like ours come in. It’s really an important issue for any business looking to reap the benefits of graphene (or any other nanomaterial, for that matter) in their products. Often using the wrong material can either have no benefit at all, or even make product performance worse. A particular example would be composite materials like graphene-reinforced plastics; if a poor-quality graphene material is used it can cause parts to fail instead of providing the improved strength expected. This can be a big issue for industries such as automotive and aerospace, where there is enormous effort behind replacing heavier metal parts with lighter composite materials (like carbon fiber) that are just as strong. If graphene and other nanomaterials are to play a role in reducing weight and cost then agreed standards are really important.”

Aline Amorim Graf is a co-author of the paper in the team at the School of Mathematical and Physical Sciences at the University of Sussex. She said:

“Some manufacturers say they produce graphene but actually—no doubt inadvertently—produce a form of graphite. Some will charge up to £500 per gram. The trouble is there’s no standardization. What we’ve done is to create a new way to measure the quality of nanomaterials like graphene. We use a Raman spectrometer to do this, and have created an algorithm to automate the process. In this way, we can determine the quality, size and thickness of the sample. Clearly the quality of graphene really matters. If you’re using graphene to strengthen structures, to use in health monitors, to use in supermarket tags, you want to know you’re getting the real stuff. But actually purchasers of graphene have no clue as to the quality of what they’re buying online. If you’re using graphene to strengthen cement, and it turns out it’s actually not graphene or is low quality graphene, then that’s going to matter.”

Professor Alan Dalton, co-Director of the Sussex Program for Quantum Research and co-author of the paper, said:

“This is truly an important area of research for our team. We believe that our new metric will be of great help to industry, researchers and standards bodies alike who are key-stakeholders in the development of 2-D materials towards commercialisation.”

The Graphene Council has long called for better standardization. Terrance Barkan of the Graphene Council has written:

“The lack of an agreed global standard for graphene and closely related materials creates a vacuum and lack of trust in the marketplace for industrial scale adoption of graphene materials.”