Sometimes friction is good, like the friction between the road and a car’s tires to keep the car from rolling over. And sometimes friction is bad – if you don’t put oil in the same car, there will be so much friction in the engine that the car can’t run. The condition of the material known as high lubricity (Water can be the key to “transformation” a lot), where the friction between the two communicating surfaces is almost non-existent, is what makes the material that researchers study up to many years due to the ability to reduce energy consumption and wear of devices. However, there are times when friction is required in the same device, and the ability to turn super-lubrication on and off will be a boon for many practical engineering applications.

Seong Kim, Associate Professor of Chemical Engineering and Chairman of the Department of Chemical Engineering at Penn State, and Zhe Chen, a researcher at the State Key Laboratory of Fluid Power and Mechatronic Systems at the Department of Mechanical Engineering at Zhejiang University, suggested that Research and Applied Materials Today and this change can be seen very well in water. Specifically, water vapor and phenol vapor, which is a family of organic compounds.

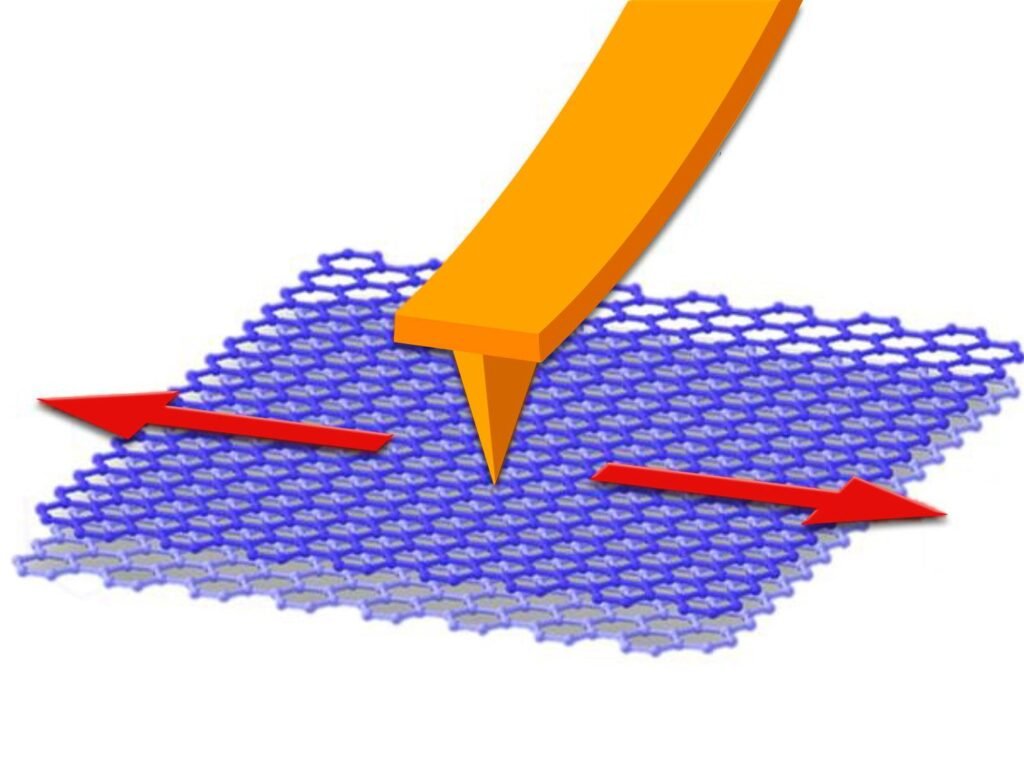

Super-lubricity (Water can be the key to “transformation” a lot) is an important feature of some two-dimensional (2D) materials, which have a third layer, especially graphene and molybdenum disulfide. Graphene is often used as a solid lubricant, in the form of coatings on various materials such as metals and plastics. With graphene, the atoms are arranged in a hexagonal pattern, which forms this landscape of mountains and valleys, like a quilt.

“When you go to the store to buy a 36-ounce bag, you have peaks and valleys, patterns that fluctuate,” Kim said. “If you put two crates on top of each other with the holes facing each other and aligned, it’s very difficult to slide over each other because the edges of one are and valleys and each other. And if you turn this a little so that the figures do not enter the valley, they can easily move out and therefore graphene can have a great lubricity.

Reducing friction to near zero is helpful to reduce wear and tear on working tools and to save energy. But it can also be unwanted.

“Because friction causes about 25% to 30% of the energy in trucks and cars, and can tear down parts of the machine, removing it can be good,” Kim said. “However, you can imagine that if we remove friction completely, we have no traction. If we have no traction, it makes it difficult for a car or other machine to control its movement.

This makes the ability to turn the super-lubricity on and off necessary; However, this has long been considered difficult, if not impossible, to do. In recent times, this large-scale coercion has become possible, with considerations related to mechanical strength, exposure to light, etc. as a possible way to disable it. However, Kim and his team have found promising results by changing the environment, namely by humidifying the water with water and phenol vapor.

They used silicon oxide probes and graphite basal planes to show how this was possible. Silicon is commonly used in microelectromechanical systems (MEMS) that have small moving parts and are used in devices such as accelerometers in the Apple Watch and smartphones to measure speed.

The researchers found that nanoscale superlubrication between the silica surface and the graphene surface can be achieved through the diffusion of various molecules from the environment. They found that ultra-low friction could be increased 25 times by water vapor and 45 times by phenol vapor. When water is adsorbed on silica, it forms a nanostructure similar to what it has in its solid state, ice. “As we increase the humidity, the water sits on top of the silicon dioxide,” Kim said. “We can rearrange the structure so that the ice network matches the graphite network. Atomic ripples match, then tension increases.

This study shows that if we can develop a way to control the water on the surface of the material, it will allow the silica to flow over the graphite in an artistic way. Once we’ve done that, we can turn super-lubrication on and off.

Among the other steps of this research will be the update of the process to allow the acceleration of the process. Kim said that although large-scale applications of large-scale switches may be a long way off, MEMS applications in devices such as smartphones and Fitbits will be possible in the near future.

“Because they are such small devices, the actuation force is so low that any friction can kill the device, and then, to avoid such failure problems, many MEMS devices have a chlorinated carbon cover, but they are organic coatings,” Kim said. “Then these organic coatings can’t last long because they’re boring. But if we can apply graphene as a coating and control the tension, then we can have better motion control. Engineers can also revisit old, original equipment and technology that was developed but could not be used due to the friction problem. This can lead to better devices, or even new devices.

Kim also said that this research paper is a basic translational study, but he pointed out that the findings made in this research address the importance of basic science.

“We wouldn’t be able to make that kind of discovery if we looked at our posts and didn’t do the basics,” Kim said. “Some may think that progress comes naturally, but there is a lot of effort that goes into it. We cannot forget to do the basic science that leads to these research collaborations and discoveries.”