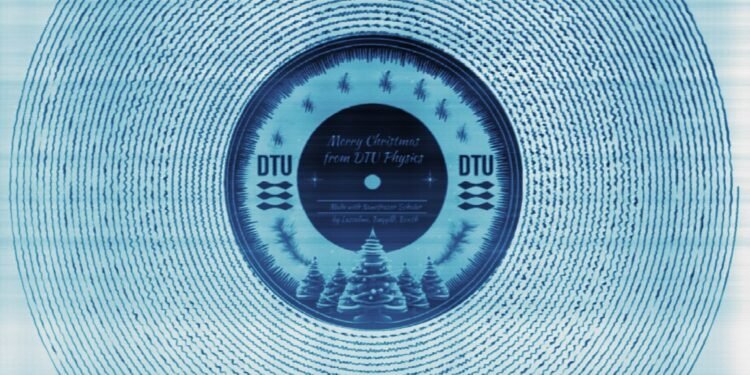

Just in time for Christmas, a world record was set at DTU. The researchers extracted the material from Rocking Around the Christmas Tree from a 40-micrometer-wide disk.

Measuring just 40 micrometers in diameter, DTU Physics researchers achieved (a world record was set at DTU) the smallest record ever. Showing the first 25 minutes of the Christmas classic “Rocking Around the Christmas Tree,” a nano-shaping machine – the Nanofrazor – was recently acquired from Heidelberg Instruments. Nanofrazor can place 3D patterns on its surface with nanometer resolution, allowing researchers to create new nanostructures that can open the way for new technologies in areas such as quantum devices, magnetic sensors, and electronics.

“I’ve been doing lithography for 30 years, and even though we’ve had this machine for a while, it’s still like science fiction. We did a lot of experiments, like making a Mona Lisa in an area of 12 by 16 micrometers with pixels of 10 nanometers. We also printed an image of the founder of DTU – Hans Christian Ørsted – in 8 by 12 micrometer format with 2,540,000 DPI pixels. To get an idea of the scale we are working on, we can use this material to write our signature on red blood cells,” says Professor Peter Bøggild of DTU Physics.

“The most amazing thing is that we can create free 3D shapes at this crazy resolution – this grayscale nanolithography is a game changer for our research.

” Nanoscale Christmas Disc – in stereo

Nanofrazor is not like a printer that adds things to the medium; instead, it works like a CNC (computer numerical control) machine that removes material from the right place, leaving the desired shape behind. In the case of the Mona Lisa picture and H.C. Ørsted thumbnail, the final image is defined by lines that remove the polymer until a perfect gray image appears. For Peter Bøggild, a budding musician and vinyl record enthusiast, the idea of burning nanometric records is a no-brainer.

We decided we might as well try printing a disc. We’ve taken a snippet of Rocking Around The Christmas Tree and cut it like you would a normal disc, although since we’re working on the nanoscale, this isn’t possible with your average turntable. The Nanofrazor was put to work like a record-cutting lathe – turning the signal into a circular hole in the sky. In this case, the backing is a different polymer than vinyl. We even recorded music in stereo – the sidebar is the left channel, while the depth has the right channel. It may not be very important and expensive to be a music recording. To read the space, you need an expensive atomic force microscope or a Nanofrazor, but it is completely doable.

Nanostructures are very fast, cheap

The NOVO Foundation’s BIOMAG grant, which made the Nanofrazor dream possible, is not about cutting Christmas discs or printing images of celebrities. Peter Bøggild and his colleagues, Tim Booth and Nolan Lassaline, have other plans. They hope that the Nanofrazor will allow them to create 3D nanostructures in a perfect way and to do it at a high speed and at a low cost, which is not possible with the current devices.

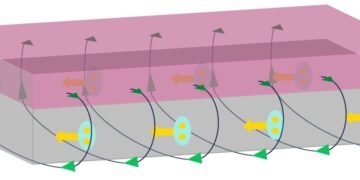

“We work with 2D elements, but when these very important elements are carefully placed on the 3D surface, they follow the contours of the surface. In short, they bend, and it is a strong and completely new ways of “programming” things that no one would have believed possible just fifteen years ago. For example, when twisted in the right direction, graphene acts as if there is a large magnetic field when in fact there is none. And we can use the Nanofrazor to lower it in the right direction,” explains Peter Bøggild.

Associate Professor Tim Booth adds:

“The fact that we can now shape its surface with nanometer precision is conceptually a game-changer for us. We have many ideas for what to do next and believe that this machine will do incredibly fast prototyping of new structures. Our goal is to develop a new magnetic sensor to detect fluid in the living brain within the framework of the BIOMAG project. However, we are passionate about creating moldable surfaces that can effectively handle electromagnetic waves. There is a lot of work to be done.

Postdoc Nolan Lassaline (who broke the Christmas record) recently received a DKK 2 prize. VILLUM EXPERIMENT offered to create a “soap bar” with graphene. He will use the grant – in Nanofrazor – to explore new ways to process nanomaterials and to create new ways to recycle electrons into important materials.

“Quantum soap is a flat electronic potential to which we add dynamic disorder. By doing this, we can control how electrons pass through graphene. We hope to understand how electrons move within the functional potential and find out if this can be a new platform for advanced neural networks and numerical information processing.

The Nanofrazor system is now part of DTU Physics’ special NANOMADE production facility for atmospheric 2D materials and devices and is part of E-MAT, a large environment for the design and production of nanomaterials with an impact on the atmosphere of Professor Nini Pryds, DTU Energy and – lead .