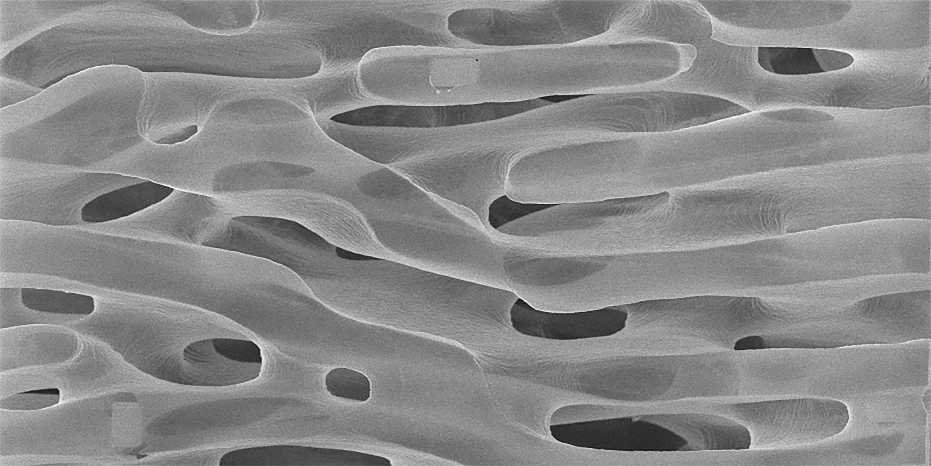

Magnified view of the new material. The pores have a diameter

of around one hundredth of a millimetre. The shells around the pores are

just 10 to 20 nanometres thick. (Photograph: Caltech / Carlos Portela).

Materials with a defined nanostructure can have surprising properties. One example is a lightweight ceramic that springs back to its original shape, like a sponge, after being compressed. One day, such materials could be used in ultrasensitive tactile sensors or advanced batteries. A team of engineers from ETH Zurich and the California Institute of Technology (Caltech) in Pasadena has now developed a new way of manufacturing such materials.

Until now, the only way to produce these materials was layer by layer in painstaking 3D printing processes, and then only in small quantities. The new method makes this much easier. Under the leadership of ETH Professor Dennis Kochmann and Caltech colleague Julia Greer, the scientists blended two liquid polymers into a finely distributed emulsion. Next, they allowed the polymers to separate and then fully harden, before dissolving one of the two components out of the material. This created a network of extremely fine labyrinthine pores. The researchers coated this porous body with aluminium oxide. Finally, they dissolved the second polymer component, leaving behind a nano‑network of extremely thin “shells” of aluminium oxide.

No edges or corners

With this new technique, the researchers managed to create samples of such a material on the cubic-centimetre scale for the first time. “We couldn’t 3D print this much nanoarchitected material even in a month; instead we’re able to grow it in a matter of hours,” says Carlos Portela, postdoctoral scholar at Caltech.

By virtue of its special shell structure, the material is extremely lightweight yet also extremely stiff and strong. This is because the shells have no corners or junctions (and therefore no internal weak points). Tests have shown that the new material has strength-to-density ratios comparable to some types of steel – and yet the material can still be compressed like a sponge. Even after repeated compression up to 30 percent, it showed only marginal signs of damage.

As a next step, the team is planning to optimise the process such that they can precisely control the inner material structure during production. In addition, the researchers are pushing for the production of larger volumes of the material.