Nature creates layered materials like bone and pearls that become less prone to flaws as they grow older. Now, researchers have created – using biomimetic proteins modeled on squid teeth, the circular appendages on squid tentacles used to capture prey – the material 2D layered composite materials is shatter proof and extremely stretchy.

“Researchers have rarely reported this interface property for bone and jade,” said Melik Demirel, Lloyd and Dorothy Foehr Huck, Professor of Bio mimetic Materials and director of the Center for Advanced Fiber Technologies, Penn State.

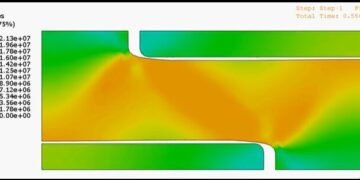

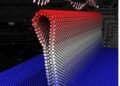

Because it is difficult to measure experimentally. . 2D composites are made up of atomic layers of a hard material, such as graphene or MXene – usually a transition metal carbide, nitride, or carbonitride – separated by layers of some sort of material to bond the layers. together. While large blocks of graphene or MXenes have bulk properties, the strength of 2D composites comes from the interface properties. “Because we’re using an interface material that we can modify by repeating strings, we can fine-tune the properties,” says Demirel. “We can make it very flexible and very powerful at the same time.”

He notes that materials can also have unique modes or properties of heat conduction, radiating heat in one direction more strongly at 90 degrees. The results of this work were published today (July 25) in the journal Proceedings of the National Academy of Sciences. “This material would be ideal for running shoe insoles,” says Demirel. “It can cool the foot, and repeated flexing won’t break the sole.”

These 2D composites can be used for flexible printed circuits, mobile devices and other devices that require strength and flexibility. Traditional continuum theory doesn’t explain why these materials are both strong and flexible, according to Demirel, but simulations have shown that interfaces are important. What seems to happen is that with a higher proportion of material made up of the interface, the interface breaks in places when the material is in tension, but the material as a whole doesn’t break. “The interface is broken, but the materials are not,” says Demirel. “We were expecting them to become compliant, but suddenly it’s not just compliant, it’s super elastic.”

Others working on this Penn State project are postdoctoral fellow Mert Vural; Tarek Mazeed, postdoctoral fellow; Oguzhan Colak, PhD student; and Reginald F. Hamilton, associate professor; all are in the Faculty of Engineering and Mechanical Science. Dong Li and Huajian Gao, professors of mechanical and aeronautical engineering, at Nanyang Technological University in Singapore, are also undertaking the study.