Members of Prof. ZHANG Tao at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS), in collaboration with Prof. HOU Yang from Zhejiang University and Professor XIAO Jianping from Dalian Institute of Chemical Physics of CAS, proposed a a two-dimensional (2D) nanoconfinement strategy improves oxygen evolution efficiency ratio (OER), metal-organic frameworks with low conductivity. (MOF). The results were published in Nature Communications.

The development of high-performance electrocatalysts for the electrochemical conversion of water to make hydrogen energy in an environmentally sustainable manner has attracted much attention for decades.

Despite the critical role played by OER in water splitting, OER at the anode requires a high thermal conductivity to increase the water splitting kinetics. Due to their large surface area, adjustable porosity, different materials and metal surfaces, MOFs have become promising candidates for efficient OER electricity generators. However, the poor catalytic behavior of most MOFs severely limits their catalytic activity.

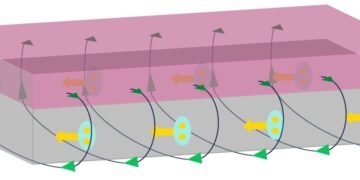

To solve this problem, NIMTE researchers proposed an electrochemical strategy to intercalate MOFs between graphene multilayers through two electrochemical processes, thus providing low-performance MOFs with improved catalytic performance better.

The prepared NiFe-MOF//G appears to show a very low peak voltage of 106 mV to 10 mA cm-2, demonstrating the pristine NiFe-MOF as well as other previously reported MOFs in their structure. In addition, the NiFe-MOF // G electrode is very good, which can continue to work for more than 150 h at 10 mA cm-2 without obvious failure in performance.

Remarkably, the results of X-ray absorption spectroscopy experiments and density theory calculations show that the nanoconfinement of graphene multilayers optimizes the electronic structure and the catalysis center of the MOF material and the formation of the species highly reactive NiO6-FeO5 distorted octahedrals in MOF arrangement. In addition, nanoconfinement reduces the limiting capacity of water oxidation reactions.

The nanoconfinement feature can be applied to other MOFs with different structures, improving their electrocatalytic activity. So far, this work challenges the common understanding of pristine MOFs as inert catalysts and reveals the potential of low conductive or even MOF coatings in electrocatalysis applications.