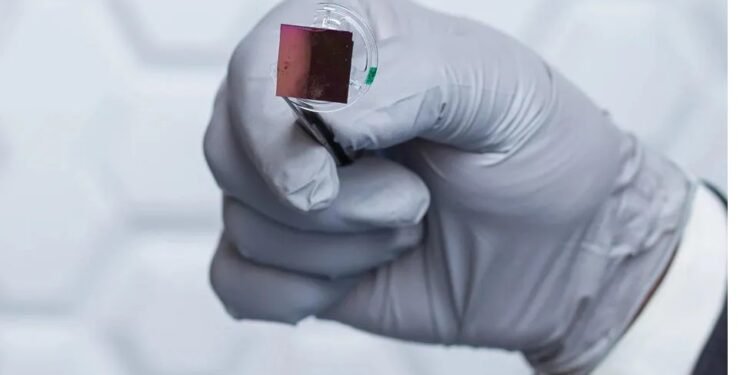

A silicone device that can transform human tissue into blood vessels (A non-invasive nanochip device) and nerve cells has moved from the prototype stage to prototype manufacturing, which means it can be manufactured anytime and anywhere. As reported in Nature Protocols, this work, developed by researchers at the Indiana University School of Medicine, brings the device closer to its use as a treatment for people with various medical conditions.

The technology, called tissue nanotransfection, is a non-invasive nanochip device that can reprogram tissue function by applying non-invasive electrical currents to deliver genes directly to make small minutes. In laboratory tests, the device successfully converted tissue into blood vessels to effectively repair injured legs. The technology is now being used to regenerate tissue for a variety of treatments, such as repairing brain damage caused by stroke or preventing and reversing nerve damage caused by diabetes.

“This report on how to create specific tissue nanotransfection chips will allow other researchers to participate in this new development of medicine,” said Chandan Sen, director of the Indiana Center for Regenerative Medicine and Engineering, vice Vice President Research Associate and Emeritus Professor and the IU School of Medicine. Sen also leads the Regenerative Medicine and Engineering Science Pillar of the IU Precision Health Initiative and is the leader of this new edition.

“This small silicon chip enables nanotechnology to change the function of living organs,” he said. “For example, if a person’s blood vessel is damaged as a result of a traffic accident and he needs a blood transfusion, we can no longer rely on the existing blood vessel because it has been broken, but we can to make the tissue into a blood vessel.and save the organ in danger.

In the journal Nature Protocols, the researchers published a technical description of how the explosion was made.

Sen said the information from this invention will lead to further development of the chip in the hope that it will one day be used in hospitals in many settings around the world.

“It’s about engineering and manufacturing chips,” he said. “The process of nanofabricating chips usually takes five to six days and, with the help of this article, anyone with experience and skills can do it.”

Sen said he hopes to get FDA approval for the chip within a year. Once it receives FDA approval, the device can be used for clinical research on people, including patients in hospitals, medical facilities and emergency rooms, as well as in other emergencies by first responders or soldiers.