A research group of Professor Minoru Osada and postdoctoral researcher Yue Shi at the Institute for Future Materials and Systems (IMaSS) at Nagoya University in Japan, has developed a new technology to create (Highly 2D Nanosheets can be Achieved) thin nanosheets. two-dimensional material films a few nanometers thick, in about a minute.

This technology helps to create high-quality nanosheet films with one click without the need for special knowledge or technology. It is hoped that their findings will contribute to the development of industrial production processes for various types of nanosheet devices.

The study was published in ACS Applied Materials & Interfaces (“Automated One-Door Assembly for Easy 2D Film Deposition”).

Nanosheets have thicknesses measured in nanometers. Nanometers are so fine that the sheet cannot be seen from the side with the naked eye. They can be used in many different fields, including electronics, catalysis, energy storage, and biomedicine.

Those made from graphene and inorganic nanosheets are being tested for use in many devices, from solar cells to sensors and batteries, as they have different electrical functions, transparency and heat resistance than materials.

However, the methods used to produce these thin films, such as the Langmuir-Blodgett method, require expert work and complex conditions. “Using existing methods, it takes about an hour to make one layer,” Osada said. “This creates a major breakthrough in the production of nanosheets.”

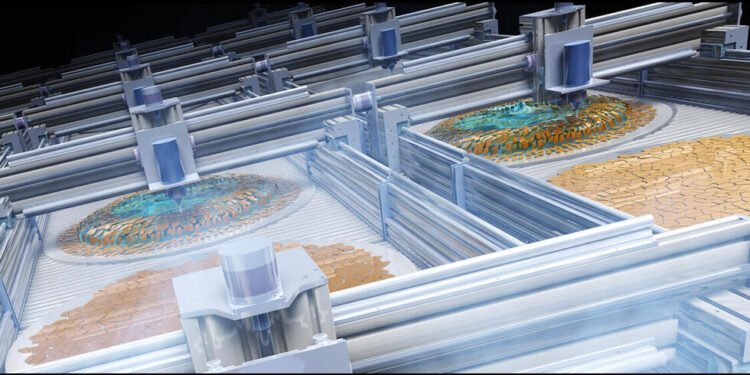

The team aims to develop a new method that can produce high-quality monolayer films and nanosheets easily and in a short time. They developed an automated film production system that produces nanosheets in about a minute with a single drop of colloidal liquid on a heated substrate on a hot plate using an automated pipette.

Then they followed that up by looking for a solution and removing the liquid. The result is a perfectly single-layered film with no gaps between the nanosheets. “Reducing the surface tension of the colloidal water solution and promoting nanosheet convection removed the discontinuity in the space between the nanosheets and allowed us to control its structure,” Osada said.

“The construction of a layer of a multilayer film in which the size of the nanosheets is controlled is possible by carefully manipulating the production process of the film of a single layer.”

“The newly developed method is expected to be an important technology such as the production process of important industrial films and the nano-coating process for nanosheets because it is simple, fast, and requires only a small solution to create a large surface.

“The technology is based on simple and vacuum operation using an automatic pipette and does not require knowledge or technical expertise. This technology is applicable to nanosheets of different composition and structures, such as oxides, graphene and boron nitride, that can produce films on substrates of different shapes, sizes and materials, making it a very versatile film.

Source: Nagoya University