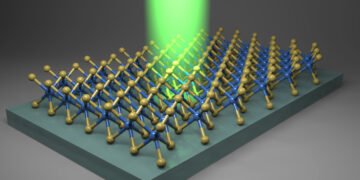

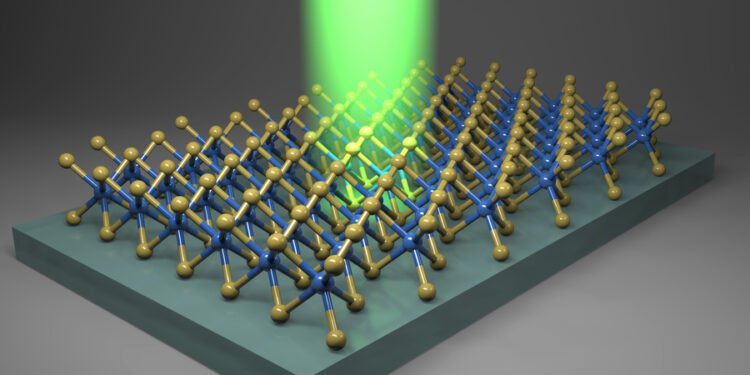

Two-dimensional materials, which consist of a single layer of atoms, can be stacked together more than conventional materials, so they can be used to make transistors, cell cells, LEDs, and other electronic devices, application and works well (How 2D things spread).

The next limiting factor of these electronic devices is the heat they generate when in use. Conventional electronics reach temperatures of about 80 degrees Celsius, but the components in a 2D device are so compact in such a small area that the device can be twice as hot.

This increase in temperature can damage the device. This problem is compounded by the fact that scientists do not fully understand how 2D objects expand as temperature increases. Because the materials are so thin and transparent, their coefficient of thermal expansion (TEC) – the tendency of a material to expand as temperature increases – is almost negligible behavior to check using standard methods.

“When people measure the amount of light expansion of a large object, they use a microscope or a microscope because you can measure them with a large object. The challenge with 2D objects is and we can’t really see them, so we have to turn to a different ruler to measure TEC,” says Yang Zhong, a graduate student in mechanical engineering.

Zhong is the lead author of a research paper that shows such a “leader”. Instead of directly measuring how the material expands, they use laser light to vibrate the atoms that make up the material. Measuring 2D objects on three different surfaces or objects allows them to accurately calculate the spread of light.

The new study shows that this method is correct, obtaining results that are consistent with the system design. This approach confirms that the TEC of 2D objects is in a much narrower range than previously thought. This information can help engineers design next-generation electronic components.

“By supporting narrow physical boundaries, we give hardware engineers greater flexibility to choose lower yields when designing devices. They don’t want to create new crops just to reduce heat stress. We believe this has very important implications for the electronic device and packaging community,” said lead author and former engineering graduate student Lenan Zhang SM ’18, PhD ’22, who is a scholar science now says.

Authors include author Evelyn N. Wang, Ford Professor of Engineering and head of MIT‘s Department of Mechanical Engineering, and others from MIT’s Department of Electrical and Computer Engineering and Department of Mechanical Engineering with input from University of Southern Science and Technology. in Shenzhen, China. The research is published in Science Advances.

A shock visit

Because 2D objects are so small – perhaps only a few microns – standard tools are not sensitive enough to directly measure their expansion. In addition, the materials are thin enough to be bonded to substrates such as silicon or copper. If a 2D material and its substrate have different TECs, they will expand in different directions as the temperature increases, causing thermal stress.

For example, if a 2D material is attached to a substrate with a high TEC, when the device heats up, the insert expands more than the 2D material, which stretches it. This makes it difficult to measure the actual TEC of a 2D object since the grain affects its expansion.

The researchers overcame these problems by focusing on the atoms that make up 2D objects. When a substance heats up, its atoms vibrate at short intervals and move apart, causing the substance to expand. They measure these using a technique called micro-Raman spectroscopy, which involves hitting the material with a laser. Vibrating atoms scatter laser light, and this relationship can be used to determine their vibrational frequency.

But as the grain expands or contracts, it affects how the atoms in the 2D material vibrate. The researchers need to delete the effects of this fruit to focus on the properties inside the material. To do this, they measured the acoustics of the same 2D material in three different materials: copper, which has a high TEC; fused silica, which has a low TEC; and a silicon substrate with small holes and defects. Since the 2D object hovers over the holes in this latter seed, they can make measurements in these small areas with vertical objects.

The researchers then placed each seed on a heating pad to control the temperature, heated each sample and performed micro-Raman spectroscopy.

“By performing Raman measurements on the three samples, we were able to extract the so-called yield-dependent heat coefficient. “By using these three different materials and knowing the TEC of silica and fused copper, we can extract the TEC of the 2D material,” Zhong says.

The results are spectacular

They performed this analysis on a number of 2D objects and found that they all fit in the formula. But the researchers found something they didn’t expect: 2D objects fit into a hierarchy based on their constituents. For example, 2D materials with molybdenum tend to have a higher TEC than those with tungsten.

The researchers dug deeper and learned that this process is caused by an important atomic property known as electronegativity. Electronegativity describes the tendency of atoms to attract or withdraw electrons when they bond. It is listed in the periodic table for each element.

They found that the greater the difference between the electronegativities of the 2D material, the lower the thermal expansion rate of the material will be. An engineer can use this method to quickly estimate the TEC for any 2D object, instead of relying on complex calculations that usually require a computer to handle it, Zhong said.

“An engineer can look at a time table, get the electronics of the corresponding components, put them in our connection design, and in a minute, they can get a good plan of the TEC. This is very promising for the rapid selection of materials for engineering applications,” says Zhang.

In the future, the researchers want to apply their method to many other 2D objects, perhaps by creating a database of TEC. They also wanted to use micro-Raman spectroscopy to measure the TEC of various materials, which combined many 2D materials. They also hope to reveal why the light expansion of 2D objects differs from that of bulk objects.