By Dr Rina Singh

The author is Senior Scientist, Transport Planning and Environment Division,

CSIR-Central Road Research Institute, New Delhi

India ranks second in having largest road network across the world. As a long term goal of doubling the length of the national highway network, the National Highways Authority of India plans to build 50,000 km of roads by year 2022. In the next five years, The Government of India has decided to invest around Rs 7 trillion for the construction of new roads and highways. The Indian roads carry almost 90 per cent of the country’s passenger traffic and around 65 per cent of its freight. Therefore, there is a need to focus on developing new construction materials in order to overcome the disadvantages of conventional materials, by using knowledge of materials science and nanotechnology.

In order to meet the increasing traffic volume and traffic load demands, India needs usage of new innovative materials in road construction over conventional construction materials. The disadvantages of using convention materials includes: cost, incompatibility between certain aggregates and binders (bituminous or cementitious), durability issues in extreme environmental conditions and deterioration over time. This need is the driving research to develop the next generation materials based on nanotechnology.

Concrete and asphalt are the widely used pavement materials, however, they are expensive. In spite of the fact that these pavement materials are used on a large scale and in huge quantities for road constructions, the mechanical behaviour of these materials depends to a great extent on structural elements and phenomena which are effective on a micro and nano-scale. Therefore nanotechnology based innovations with these materials can improve performance and durability, which in the long run can lead to a cost effective solution for road pavement.

Nanoscience also known as an interdisciplinary science is the study of structure and materials at nanoscale level. It has been widely used in the field of Microelectronics, Plasmonics, Clean water technology, Biotechnology, Medicine and Materials sciences. However, its potential for application in the area of transportation and construction engineering is still growing. The main benefit that nanotechnology can provide to construction engineering is through the improvement of existing materials by knowing the physics and chemistry of existing materials at nanoscopic scale for the development of novel materials.

The emerging fields of nanoscale science, and its ability to work at the atomic and molecular level, to create structures with fundamentally new properties and functions are leading to a new understanding and control over the basic building blocks and properties of all natural and man-made materials, such as asphalt and concrete. In light of growing concerns about environmental and health protection, the techniques and processes used for energy savings and natural materials should be redesigned and new materials should be invented. This is only possible if better knowledge of the complex behaviour of asphalt/concrete material at nanolevel is developed.

Nano in Asphalt Pavements

Asphalt also known as bitumen is the binder agent that binds more than 90 per cent of highways together. Increased traffic loads and traffic volume, combined with the rising cost of asphalt/bitumen, have led to an urgent need to improve the durability, safety, and efficiency of asphalt pavements through asphalt modification. Asphalt is the most recycled material. Therefore, it is one of the main ingredients in a sustainable pavement. Asphalt binder is a mixture of wide variety of hydrogen and carbon compounds. Some are aliphatics, some are aromatics and some molecules have both aromatic and aliphatic carbon.

These components appear to vary widely in molecular size and it is the known tendency of polar molecules to form molecular association and such association are usually hold together by weak forces compared with the bonding forces that hold individual atoms together in molecule. It is known that polar associates in asphalt are of great importance in influencing asphalt properties and therefore it is important to introduce a model of asphalt structure in which molecular association are control. Current research does not provide sufficient information on how these microstructure influences the rheological properties of asphalt binders on pavement performance and also lacks characterization tests to look inside materials and to determine their intrinsic properties.

Moisture damage (Figure 1) is major complex problem in asphalt. Only by understanding what is really happening in practice at micro/nano level, knowing the driving forces of failure mechanisms and knowing which intrinsic parts of the mixing components are responsible for the behaviour of a material it is possible to take the right measurements to reduce or prevent failure. Therefore knowledge and experience with matter at nano-level are necessary to support the objective driven creation of new materials and systems with pre-defined properties and behaviour.

In pavement engineering mostly macroscopic techniques are used for characterization of materials. However, there are still problems in asphalt pavement area that have not been understood and solved yet using macroscopic characterization and moisture induced damage in asphalt remains an unsolved problem. Since water is a polar molecule it can be transported into the asphalt by virtue of attraction of polar water molecules to polar asphalt components. When water penetrates the asphalt concrete the mechanical strength get reduced, so it is very important to assess the damage mechanism of asphalt pavement by studying diffusion behaviour of water molecules inside asphalt matrix.

Moisture damage in asphalt can occur through the loss of adhesion and cohesion between binder and aggregates. The breaking of bond between aggregate and binder is a nanoscale phenomena and therefore macroscale characterization becomes inadequate for understanding moisture interaction with asphalt-aggregate bonds. Till now macro and micro scales phenomena are not able to solve the problem of aggregate-binder bond distortion in presence of moisture. As a result moisture damage of asphalt remains one of the most complex problems of asphalt binders which require immediate attention for researcher in this field. In this regard research efforts are being pursued to develop nano modified bitumen. Such product is expected to play a larger role in the development of future pavement materials.

The nanomodification of the bituminous materials has the potential to open up whole new uses and classes of bituminous materials (nanoclay, nanosilica, Carbon nanotubes, TiO2 modified bitumen), with wide ranging implications for the construction and transportation sector. There are no other asphalt modifiers on the market that work on a nanoscale. The majority of the products that are used with asphalts are simply additives which don’t do anything to the chemistry of the asphalt, rather just improving specific properties such as binding, flexibility etc however, using nanomaterials as a catalyst unlike polymer additives reacts with bitumen and change the chemistry and the molecular structure of the bitumen under the influence of temperature and oxygen and thus act as anti-stripping agent by improving the hydrogen bond. Because of the large surface area of the nanoparticles, a small volume fraction of the particles in the material is sufficient to form an acceptably amount of adsorption boundary layer phase so that the macroscopic properties of the resulting composites, such as viscosity, toughness and cohesiveness can be improved.

Nanoclays (Figure 2) are the new generation of processed clays of interest in a wide range of high performance composites. Nanoclay is defined as clay that can be modified to make the clay complexes compatible with organic monomers and polymers. It is intended to improve the performance characteristics of asphalt, to increase the durability of asphalt roads and to make a contribution to the improvement of environmental conditions, by energy and resource savings. Therefore knowledge and experience with matter at nano-level are necessary to support the objective driven creation of new materials and systems with pre-defined properties and behaviour. Managing the behaviour and performance of asphalt mixtures will be the greatest challenge for the coming decades.

Nano in Concrete

Currently, the most active research areas dealing with cement and concrete are: understanding the hydration mechanism of cement particles and the use of nano-size ingredients such as alumina, silica and Ti02 particles. Addition of nano-silica cement based material controls the degradation of the fundamental C-S-H (Calcium-silicate-hydrate) reaction in water as well as block water penetration and therefore improve durability. The addition of nano SiO2 particles enhances the density and strength of concrete. TiO2 is a photocatalytic material that can break down almost any organic compound when exposed to sunlight. Because of the hydrophilic nature it provides self cleaning properties to surfaces to which it is applied.

Knowledge at the nanoscopic level of the structure will promote the development of new applications and new products to repair/replace or improve the properties of construction materials. Although known for thousands of years, concrete still offers plenty of opportunities to innovative industries. The mechanical behaviour of concrete materials depends to a great extent on structural elements and phenomena that are effective on a micro- and nanoscale region. Nanotechnology improves the quality of material by changing the molecular structure of concrete.

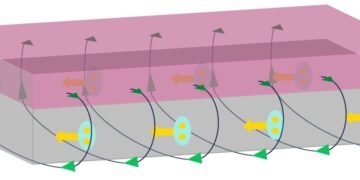

Concrete is a mixed composites in which binding phase (cement paste), pebble and sand is included. During chemical reaction between cement and water, calcium silicate hydrate (C-S-H) and lime (calcium hydroxide) are formed and this mechanism is called hydration (Figure 3). The strength in concrete comes from C-S-H gel structure which is a nanostructure in its own. The cohesion of cement and its mechanical properties are mainly due to C-S-H phase (Figure 3) of cement concrete. However, the crystal structure of C-S-H gel in cement pastes is not yet fully resolved and still debated in the scientific community. Resolving the structure of C-S-H is of prime importance, since the data could be used in the future for advanced meso or macroscopic models to assess the final mechanical properties and thus the durability of cementitious materials. The structure of C-S-H is much like clay, with thin layers of solids separated by gel pores filled with interlayer and adsorbed water (Figure 4). With movement of moisture it makes the concrete susceptible to shrinkage and cracks. Thus a better understanding of nanoscience of cement hydrates and cement material will open new paths to deal with this problem.

Hydrated cement is porous structure with gel pores (size <10 nm) and capillary pores (10 nm-1000 nm) pores (Figure 5, 6), making the path for chloride ions and other chemicals. There are many types of pores and voids in concrete that have a direct effect on permeability of concrete. Holes and vacancies in concrete can be broadly classified as gel hole, capillary punch and paste-aggregates interfacial zones (Figure 5, 6). With the progression of hydration mechanism the capillary pore starts segmenting. After hydration, capillary pores can be broken if the water to cement ratio is much lower. Inhibiting the continuity of the capillary pore in the cement paste matrix, decreases the permeability of concrete by inserting less permeable aggregates. The size of the aggregates of particles plays an important role in permeability; the larger the size, the greater the permeability. During the initial phase of hydration, the transition zone is weak. The cracks in concrete generally connect the flow path to each other and increase the permeability of the concrete and therefore affect the durability of concrete.

By incorporation of nanoparticles into concrete, the pores are filled by physical and chemical interactions, so that the concrete becomes durable and strong. By inserting carbon nanofibers (CNFs) / carbon nanotubes (CNTs) in concrete (Figure 7), it makes the concrete stronger because the nanofibers prevents concrete before the crack is formed. High surface area of nanoparticles facilitates bonding with matrix materials and its performance is better than micrometer-size particles. Nanomaterials fill the empty space which freezes free water and treats like center of crystallization for cement hydrates and increases hydration mechanism.

Carbon-based nano material improves the mechanical properties (durability) by bonding with concrete mixture (inhibits crack propagation between semantic agents and concrete aggregates). Due to high aspect ratio, low density, small size and unique physical and chemical properties, carbon nanotubes (CNTs) are considered as one of the best candidate for reinforcement in construction based materials. It imparts high bond strength due to interfacial interaction between CNTs and cement hydrates. CNTs act as bridges across cracks and voids, which ensures load-transfer in tension. The size and aspect ratio of CNTs allows distributed on a much finer scale than commonly used micro reinforcing fibers. As a result, micro-cracks are interrupted much more quickly during propagation in a nanoreinforced matrix.

Nano in Environmental Sector

The development of new materials and devices leading to ultrasensitive detection of molecules has gained an exponential growth because of their exciting features and their potential application in important fields like environmental monitoring of toxic pollutants in the concentration range between picomolar and attomolar using surface enhanced Raman spectroscopy, photovoltaic devices, optics, outstanding catalysis effect, magnetic and photonic properties, etc.

Among these fields, improvements of sensors at the nanoscale are providing new solutions in physical, chemical and environmental areas. Air and water pollutants create significant health hazards around the globe. Indeed, over the last decade, environmental pollution remediation became a global priority. Environmental pollution, caused by industries and traffic emissions, such as heavy metal ions, toxic volatile gases, can directly or indirectly damage and impact the ecosystem and greatly threaten the environmental security and human health. Environmental pollutants are widely spread in the environment and very difficult to detect at trace level.

According to a UN report highlighting the need for clean water, polluted drinking water claim more lives than all forms of violence, including war. So, early detection of contaminants is the key to initiate rapid remedial strategies. Unfortunately, the most commonly used detection methods for water and airborne pollutants require either laborious sample preparation procedures and are very time-consuming, and the in-situ sampling cannot be done in field.

Plasmonic metal nanoparticles (silver and gold) can be used for the development of rapid, cost-effective and highly sensitive sensor for the on-site detection of contaminants. The sensing capabilities enabled by gold and silver nanoparticles rely upon localized surface plasmon resonance (LSPR). Localized Surface Plasmon Resonance spectroscopy of metallic nanoparticles is a powerful technique for assessing chemical and biochemical sensing capabilities. The key factor for all these applications is the enhancement of the electromagnetic field intensity around sub-wavelength size metal particles due to coupling between the incident photons and collective oscillations of free electron at the metal surface. When excited by light of a specific wavelength, the conduction electrons on the nanoparticles surface collectively oscillate and generate a significantly enhanced electromagnetic field which makes the SERS detection limit down to the single molecular level (Figure8) .

LSPR is an extremely sensitive optical transducer, which is dependent on the type, size, shape and aggregation state of plasmonic nanoparticles as well as the refractive index of the surrounding environment. The coupling of incident light with the LSPR of plasmonic nanoparticles results in significant enhancement of the electromagnetic field near the nanoparticles surface. When analytes or molecules to be detected closely associate with the NP surface, their Raman scattering cross-section increases substantially and this allows very sensitive measurements of adsorbates on surfaces and this phenomenon is the basis for Surface Enhanced Raman Scattering (SERS) based sensing [Figure8].

SERS is a surface sensitive technique that results in the enhancement of Raman scattering by molecules adsorbed on rough metal surfaces. The enhancement factor can be as high as 1014 – 1015, which allows the technique to be sensitive enough to detect single molecules. Organic or inorganic pollutants and pathogens can be detected and differentiated based upon the finger-print spectra that arise when they enter SERS-active hot spots (Figure 9). Therefore smart sensors can replace the existing way of environmental monitoring.

Further Readings

- Meor Othman Hamzah , Muhammad RafiqKakar , MohdRosli Hainin, Jurnal Teknologi (Sciences & Engineering), 2015, 73,125–131.

- https://www.ibef.org/industry/roads-india.aspx

- M Faruqi, L Castillo, J Sai. State-of-the-Art Review of the Applications of Nanotechnology in Pavement Materials, Journal of Civil Engineering Research, 2015, 5, 21-27.

- Andrea Bede, Alexandra Scurtu, IoanArdelean, NMR relaxation of molecules confined inside the cement paste pores under partially saturated conditions, Cement and Concrete Research, 2016, 89, 56-62.

- Radoslaw M. Kowalczyk, Agata M. Gajewicz and Peter J. McDonald, The mechanism of water-isopropanol exchange in cement pastes evidenced by NMR relaxometry, RSC Advances., 2014,4, 20709-20715.

- Xiantong Yan, Hongzhi Cui, Qinghua Qin, Waiching Tang and Xiangming Zhou, Study on Utilization of Carboxyl Group Decorated Carbon Nanotubes and Carbonation Reaction for Improving Strengths and Microstructures of Cement Paste, Nanomaterials, 2016, 6, 153.

- Tae Yoon Jeon, Dong Jae Kim, Sung‑Gyu Park, Shin‑Hyun Kim and Dong‑Ho Kim, Nanostructuredplasmonic substrates for use as SERS sensors, Nano Convergence (2016), 3, 18.

- Sara Abalde-Cela , Susana Carregal-Romero, João Paulo Coelho, Andrés Guerrero-Martínez, Recent progress on colloidal metal nanoparticles as signal enhancers in nanosensing, Advances in Colloid and Interface Science, 2015, doi: http://dx.doi.org/10.1016/j.cis.2015.05.002.

- Weijun Zhu, Chu-Hua Lu, Feng-Chih Chang and Shiao-Wei Kuo, Supramolecular ionic strength-modulating microstructures and properties of nacre-like biomimeticnanocomposites containing high loading clay, RSC Advances, 2012, 2, 6295-6305.

- Saeed GhaffarpourJahromi, Ali Khodaii, Effects of nanoclay on rheological properties of bitumen binder, Construction and Building Materials, 2009, 23, 2894-2904.

- Jaesang Lee, Shaily Mahendra, and Pedro J. J. Alvarez, Nanomaterials in the Construction Industry: A Review of Their Applications and Environmental Health and Safety Considerations, ACS NANO, 2010, 4, 3580-3590.

- Johan Jacobsen, Michelle Santos Rodrigues, Mark T. F. Telling, Antonio LudovicoBeraldo, Sergio Francisco Santos, Laurence P. Aldridge & Heloisa N. Bordallo, Nano-scale hydrogen-bond network improves the durability of greener Cements, Scientific Reports, 2013, 3, 2667.

- Yang Zhang, Antonio Faraone, William A. Kamitakahara, Kao-Hsiang Liu, Chung-Yuan Mou, Juscelino B. Leão, Sung Chang, and Sow-Hsin Chen, Density hysteresis of heavy water confined in a nanoporous silica matrix, Proceedings of the National Academy of Sciences, 2011, 108, 12206–12211

- Merlin A. Etzold , Peter J. McDonald , Alexander F. Routh, Growth of sheets in 3D confinements- a model for the C–S–H meso structure, Cement and Concrete Research, 2014, 63 , 137–142.

- R. Douglas Hooton, Current developments and future needs in standards for cementitious materials, Cement and Concrete Research, 2015, 78, 165-177.

- Karen L. Scrivener, Patrick Juilland, Paulo J.M. Monteiro, Advances in understanding hydration of Portland cement, Cement and Concrete Research, 2015, 78, 38-56.

- https://en.wikipedia.org/wiki/File:Types_of_Carbon_Nanotubes.png

- https://www.sciencedaily.com/releases/2015/11/151104121041.htm

- Jens Rieger, Matthias Kellermeier, and Luc Nicoleau, Formation of Nanoparticles and Nanostructures—An Industrial Perspective on CaCO3, Cement, and Polymers, AngewandteChemie International Edition, 2014, 53, 12380-12396.

- Albert G. Nasibulin, Tatyana Koltsova, Larisa I. Nasibulina, Ilya V. Anoshkin, AlexandrSemencha, Oleg V. Tolochko, Esko I. Kauppinen, A novel approach to composite preparation by direct synthesis of carbon nanomaterial on matrix or filler particles, ActaMaterialia, 2013, 61,1862-1871.

- Mark Bediako, Augustine OseiFrimpong, Alternative Binders for Increased Sustainable Construction in Ghana-A Guide for Building Professionals, Materials Sciences and Applications, 2013, 4, DOI:10.4236/msa.2013.412A004.