A relatively new strategy (New materials mimic muscle structure and function) for making fiberglass actuators, inspired by muscle structure, could lead to advances in robotics, prosthetics and smart clothing, according to a group of scientists led by Penn State discovered (New materials mimic muscle structure and function) this process. “Actuators are any material that changes or changes under any external stimulus, such as machine parts that shrink, bend, or expand,” said Robert Hickey, an assistant professor of materials science and engineering at Penn State. “And for technologies like robotics, we need to create soft, lightweight versions of these materials that can act like artificial muscles. Our job is to really find a new way. To do that.”

The team has developed a two-step fiber actuator manufacturing process that mimics the structure of muscle fibers and excels in many respects compared to other existing actuators, including efficiency, control stress, and mechanical properties. They report on their findings today (June 2) in the journal Nature Nanotechnology.

“It’s a huge field and there’s a lot of exciting research, but it really focuses on technical materials to optimize properties,” Hickey said. “What makes our work exciting is that we focus on the connection between chemistry, structure and properties.”

Hickey previously led a team that produced self-assembled nanostructured hydrogel materials. Hydrogels are networks of polymers that can swell and retain large amounts of water while maintaining their structure.

In recent research, researchers have found that fibers made from this hydrogel material can stretch several times to their original length when hydrated and cured, and lock in high form when dried in a high state. The addition of water or heat will cause the material to return to its original size, which is promising for use as a propellant, the researchers said.

“We’re beginning to realize that these fibers are shrinking and have some interesting properties,” Hickey said. “When we started recognizing structure, we knew there were some really important things to do. And we started to realize that this structure mimics or reflects natural muscle in many ways.”

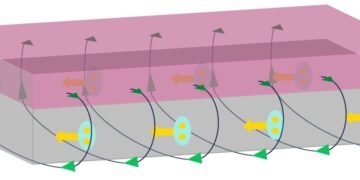

The materials are composed of high-order nanometer structures with alternating crystalline and amorphous domains, similar to the ordered and striated pattern of mammalian skeletal muscle, the researchers reported.

The unique stretching properties of hydrogels come from the combination of solid amorphous domains at the nanoscale and micrometer pores filled with water. When the hydrogels tighten, they return like a rubber band. As the expanded fibers dry in an elevated state, the polymer network will crystallize and enclose in a long fiber shape. “We think one of the main reasons we have these unique properties is that the fibers are organized directly on a nanometer scale, much like the sarcomere of human muscle,” Hickey said. “What happens is that you have the same shrinkage. These amorphous domains are all organized right next to the glass fiber, which means they shrink in one direction, creating the ability to return to their original state.”

Applying water as heat to the stretched materials can melt the crystals and return the material to its original shape. If it is five times longer than its original length, the material can return to 80% of its size and can do so in multiple cycles without reducing performance, the researchers said.

“The fact that we can use two different stimuli, heat and water, to start the drive, opens up twice as many options for materials made this way,” Hickey said. “Most actuators are triggered by a single stimulus. Dual stimuli open up the versatility of our materials.