A collaboration involving scientists from Lawrence Livermore National Laboratory (LLNL), Sandia National Laboratories, Indian Institute of Technology Gandhinagar, and Lawrence Berkeley National Laboratory has developed ultrathin 3-4 nanometer nanosheets of metal hydride that increase hydrogen storage capacity. The research appeared in the journal Small.

There is a need for sustainable energy storage technologies that can address the seasonality of renewable energy resources. Hydrogen-based technologies promise long-term solutions that reduce greenhouse gas emissions. Hydrogen has the highest energy density of all fuels and is considered an ideal solution for transportation by car, plane and ship. However, hydrocarbon-based fuel sources exceed compressed hydrogen gas in volumetric energy density, prompting the development of alternative storage methods based on high-density materials.

Complex metal hydrides are a class of hydrogen storage compounds which, while they have sufficient storage capacity, may require high pressure and temperature to achieve this capacity. The team addressed this challenge by using nano-scaling, which creates a higher surface area to react with hydrogen and reduces the depth of hydrogenation required. Previous studies have examined magnesium diboride at the nanoscale (MgB2), including the work of LLNL, however, the findings in this study were less significant and calculated to be cumulative.

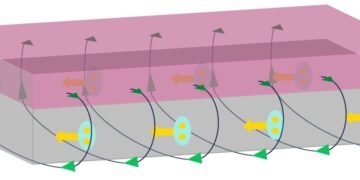

The most recent collaboration results from a solvent-free fusion of zirconia, creating a material with only 11 to 12 atomic layers and able to hydrogenate up to about 50 times the material’s capacity. This 50-fold increase in hydrogenation correlates well with a 50-fold increase in the surface-to-volume ratio, suggesting that the bulk and nanosheet materials hydrogenate the first two, a global behavior that depends on the size . For two layers on both sides of 11-12 layers of nanomaterial, this represents one third of the maximum hydrogen capacity of MgB2.

MgB2 has a substitution of magnesium and boron that transfers from the magnesium layer to the boron layer resulting in the stabilization of the boron layer. LLNL calculations reveal that the Mg coating is incomplete on the surface of the material supporting its surface structure with Mg-rich islands and other regions of boron-free surface. Working first on the problem of the surface boron layer, the calculation shows how the magnesium coating of MgB2 changes as it changes.

“These results show how reactive MgB2 surfaces with exposed boron can stabilize as they hydrogenate as the magnesium coating increases,” said LLNL scientist and author Keith Ray. “By this process, hydrogenal is reduced to hydrogenation mode.

He added, “Other nano-parts or chemical changes that are delayed or hurried to performance of the n2 as hydrogen safety,” he added.