Carbon nanotubes (No more holding nanotubes) that disperse as easily as spaghetti can use a little special sauce to reach their full potential.

Rice lab solvent simplifies industrial 3D printing from carbon nanotubes roll-to-roll and more.

Researchers at Rice University have just developed a sauce, an acid-based solvent that simplifies the processing of carbon nanotubes in a way that can be more easily extended for industrial applications.

Matteo Pasquali’s Rice Lab informs Science Advances about its discovery of a unique combination of acids that help separate nanotubes (No more holding nanotubes) into solutions and turn them into films, fibers, or other materials with good excellent electrical and mechanical properties.

A study led by graduate Robert Headrick and graduate student Steven Williams stated that the solvent (No more holding, nanotubes is compatible with conventional manufacturing processes. This would help her find a place to produce advanced materials for many applications.

“There is a growing awareness that it is probably not a good idea to increase copper, aluminum, and nickel mining,” said Pasquali, A.J. Professor Hartsook and Professor of Chemical and Biomolecular Engineering, Chemistry and Materials Science, and Nanoengineering. He is also the director of Rice-based Carbon Hub, which supports the development of advanced carbon materials for the environment. “But it has a huge chance to use hydrocarbons as our ore,” he said. “In this light, we need to extend the scope where we can use carbon materials as much as possible, especially if the metals can be transferred to a product that can be maintained from a feedstock such as a hydrocarbon”, Pasquali noted that these production processes also include pure hydrogen.

“There is a lot of carbon, we control supply chains and we know how to get it in an environmentally responsible way,” he said.

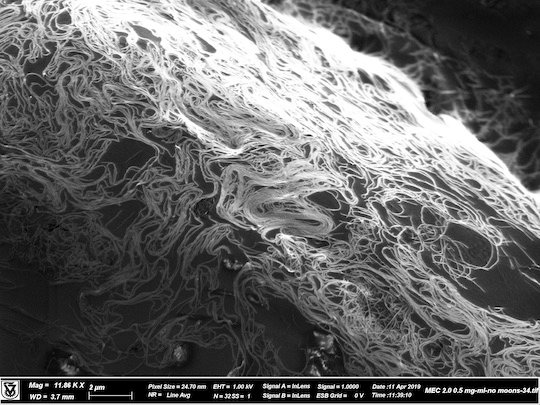

A better way to process carbon will help. The solvent is based on methanesulfonic (MSA), p-toluenesulfonic (pToS) and oleic acids, which in combination are less harmful than those currently used to process nanotubes in solution. The separation of nanotubes (which researchers call dissolution) is a necessary step before they can be extruded by a needle or other device where abrasive forces can help create these known fibers. the letter.

Oleum and chlorosulfonic acid have long been used to melt nanotubes without altering their structure, but both are more destructive. By combining oil with two weaker acids, the team has created a widely applicable process that allows the new production of products from nanotubes. “Oleum surrounds every single nanotube and gives it a local positive charge,” said Headrick, now a Shell scientist. “That accusation made them reject each other.”

After unraveling, the finer acids further separate the nanotubes (No more holding nanotubes). They found that MSA is best for fiber spinning and roll-to-roll film production, while pToS, a solid that melts at 40 degrees Celsius (104 degrees Fahrenheit), is particularly useful for 3D printing applications because it allows for nanotube solutions. . it is processed at a moderate temperature and then stabilized by cooling.

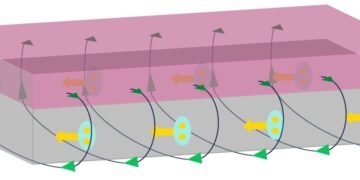

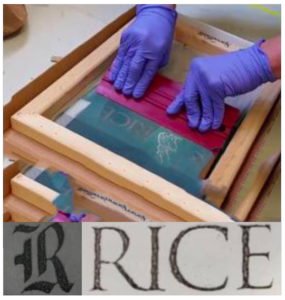

Researchers have used these powerful liquid crystal solutions to create objects in modern and traditional ways, including 3D printing of carbon airgel nanotubes and screen printing patterns on a variety of surfaces, including glass.

Researchers have used these powerful liquid crystal solutions to create objects in modern and traditional ways, including 3D printing of carbon airgel nanotubes and screen printing patterns on a variety of surfaces, including glass.

The solutions also enable the production of roll-to-roll transparencies that can be used as electrodes. “Honestly, it’s a little surprising how good it is,” Headrick said. “It worked out flawlessly on the first try.”

The researchers noted that oil is still handled with care, but once diluted with other acids, the solution is less aggressive with other materials.

“The acids we use are much finer than you can use on regular plastic,” Headrick said. “This opens the door to many processing materials and printing techniques that are already available in production plants.

“It’s also important to integrate carbon nanotubes into other devices and store them as a step in the device manufacturing process,” he said.

They state that less harmful solutions do not emit harmful fumes and are quickly cleaned after production. MSA and pToS can also recycle and process nanotubes, reducing their environmental and energy impact and processing costs.

Photo: Rice graduate student Steven Williams, left, and graduate Robert Headrick have created a recipe for an adjustable solvent from carbon nanotubes that is easier to use than commonly used acids. Courtesy: Rice University.

Williams said the next step is solvent refining for applications and determining how factors such as chirality and size affect nanotube processing. “It’s really important that we have high quality, clean pipes of big diameter,” he said.