Georgia Tech-Europe and MIT researchers (Researchers are starting a process to assemble micro-LEDs) are using emerging technology to demonstrate a system that will enable immersive and virtual reality (VR) and virtual reality displays using the world’s smallest LED array.

Add in VR headsets and chances are you’re seeing the world through a screen door. Current flat screens use pixels that are visible to the naked eye, and the small dark space between each pixel can appear as a black grid.

Now, researchers at the Georgia Institute of Technology, in collaboration with researchers at the Massachusetts Institute of Technology (MIT), have developed a new method based on 2D materials to create LED screens with smaller pixels. Powered by material-based two-dimensional layer transfer technology, the innovation promises a future of more transparent LED displays.

The team published a paper in the journal Nature in February titled “Full Color Vertical Micro-LEDs via Layer Transfer Based 2D Materials.” The authors also include researchers from Sejong University in Korea and other institutions in the United States and South Korea.

Professor Abdallah Ougazzaden of Georgia Tech-Europe and scientist Suresh Sundaram (who holds a position in Georgia Tech’s School of Electric and Computer Engineering) and MIT researchers are collaborating to disrupt the production process of LEDs – literally .

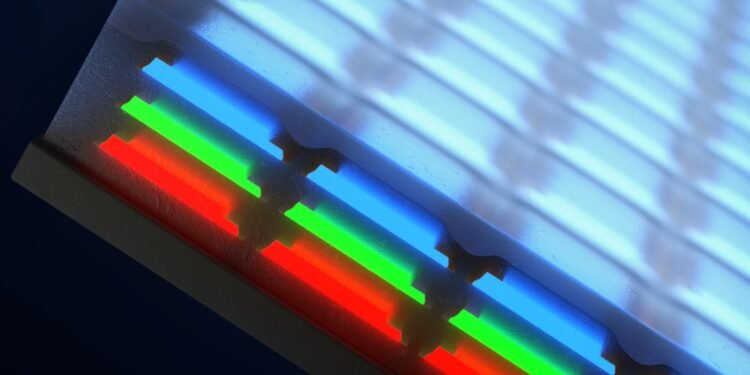

Instead of using the dominant method based on placing red, green, and blue (RGB) lights side by side, which limits pixel density, the team covered the skin RGB LED without point, achieves a matrix density of 5,100 pixels per inch. – the smallest pixel size reported to date (4 micron) and the smallest height, while delivering a full commercial color gamut.

This small vertical stack was achieved by the 2D boron nitride van der Waals epitaxy technology developed at the Georgia Tech-Europe laboratory and the graphene remote epitaxy technology developed at MIT.

The study showed that the thinnest and the smallest pixel displays in the world can work through active layer separation technology and use 2D materials such as graphene and boron to work with high-density micro-LEDs.

A unique feature of the two-dimensional layer transfer (2DLT) technique is that it allows for additional epitaxial slices. Using this expensive substrate can reduce the cost of manufacturing smaller, thinner and more realistic displays.

“We have now demonstrated that advanced 2D technology transfer and technology can outpace growth and technology transfer in specific areas,” said Ougazzaden, the Georgia Tech team’s research director. These advanced processes were developed in metal organochemical vapor deposition (MOCVD) reactors, the main equipment for wafer-scale LED production.

The 2DLT process can be replicated in many high-yield industries. The technology has the potential to take the field of virtual reality and enhancement to the next level, enabling the next generation of immersive and micro-LED displays.

This emerging technology has great potential for flexible electronics and various integrations in optoelectronics, which we believe will open up new possibilities and stimulate the industry to create commercial products from mobile displays to medical devices. “, Ougazzaden said.