Scientists at the US Department of Energy’s (DOE) Brookhaven National Laboratory have developed a new method to direct the self-assembly of several new nanoscale structures using simple polymers as starting materials. Under an electron microscope, these nanoscale structures look like miniature Lego buildings, including the blocks for ancient castles and Roman aqueducts. But instead of creating extraordinary things, scientists are investigating how this new type can affect the work of materials.

A team from the Center for Functional Nanomaterials (CFN) at Brookhaven Lab describes their new method of controlling self-assembly in a paper published in Nature Communications. The first analysis shows that different species have different electrical conductivity. The project can help guide the design of custom surface coatings with optical, electronic, and mechanical properties for use in sensors, batteries, filters, and more.

“This project opens the doors of various applications and opportunities for scientists from schools and companies to work with CFN experts,” said Kevin Yager, project manager of the CFN electronic nanomaterials team. “Scientists interested in studying eye masks, battery electrodes, or cell designs can tell us what they need, and we can choose the right method from our library of organic materials. different to meet their needs.”

Automatic calculations

In order to produce impressive results, the team relied on long-term expertise in CFN. The first is the self-assembly of the so-called block copolymers, including how different structures affect the structure and composition of these molecules. Second, a process called infiltration synthesis, which replaces the organized polymer molecules with metal or other materials to make the shape work and is easy to see in three dimensions using an electron microscope.

“Self-assembly is a very beautiful way to create architecture,” Yager said. “You create the particles, and the particles arrange themselves simultaneously in the desired order.”

In its simplest form, the process begins by applying thin films of long molecules called block copolymers to the substrate. The two ends of these block copolymers are chemically different and need to be separated from each other, like oil and water. When you heat these films through a process called annealing, the two parts of the copolymer arrange themselves to be as far apart as possible while being bonded. These chains rearrange automatically and thus create a new structure with two different chemical units. Scientists then give one of the sections metal or other material to create its shape and burn the original material completely. The result: a piece of metal or oxide with dimensions measuring only one billionth of a meter that can be useful for semiconductors, transistors or sensors.

“It’s a powerful and portable system. You can use these devices to cover a large area, “Yager said. “But the bottom line is that this system is usually only made of simple shapes – flat, sheets like nanoscale lamellae or cylinders.”

Scientists have tried different methods to overcome these simple steps. Some have experimented with more complex branched polymers. Others have used microfabrication methods to create a substrate with tiny posts or channels that guide where the polymer can go. But designing the complex materials and tools and models that lead to nano-computation can be a difficult and expensive task.

“What we’re trying to show is that there’s another way you can still use simple, cheap starting materials, and get some really interesting and weird stuff,” Yager said.

Stacking and quenching

The CFN process is based on the deposition of a thin layer of copolymer.

“We’re taking two of the things that usually need to be designed differently and layering them on top of each other,” Yager said. By changing the structure and thickness of the layers, their chemical composition, and other variables, including the time of agitation and the temperature, scientists have produced more than a dozen outliers. unprecedented nanoscale.

We found that both items did not need to be replaced. As they anneal, they want to mix,” Yager said. “Mixing allows interesting new structures to form.”

If the sweep is allowed to continue to completion, the levels will eventually begin to form a stable system. But by stopping the stress process at different times and making the equipment cool, turning it off, “you can remove passive structures and get more interesting shapes,” Yager said.

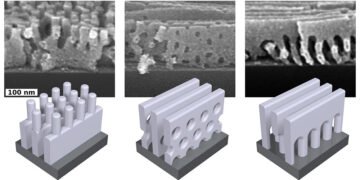

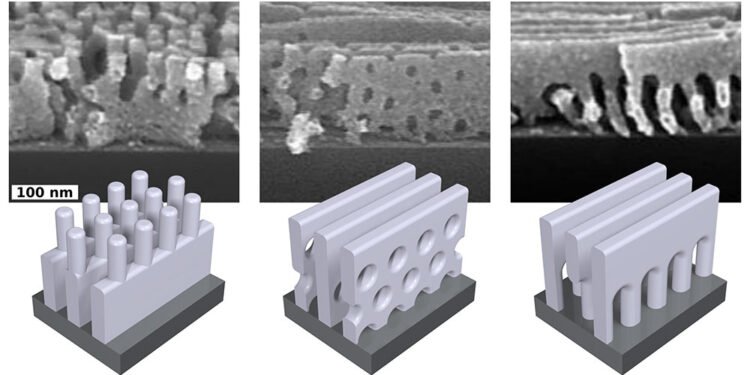

Electron imaging shows that some structures, such as “parapets” and “aqueducts”, have mixed properties resulting from the structure and reorientation of copolymers. Others have criss-cross patterns or slats with holes that don’t resemble the original design or any other self-assembling material.

Through detailed research examining the theoretical combinations of existing materials and studying their “formation history”, CFN scientists have developed a set of structural principles that describe and predict what structures will develop under certain conditions. . They used computer-based molecular dynamics simulations to better understand the behavior of molecules.

“These features allow us to see where individual polymer chains go as they rearrange,” Yager said.

The application is promising

But, of course, scientists wonder how these special things can be useful. A porous material can act as a membrane for filtration or catalysis; someone with a column-like surface could be sensitive because of its high surface area and electrical connections, Yager suggested.

The first experiment, included in the Nature Communications report, was for electrical engineering. After developing the new polymer structure, the team used an infiltration bond to replace the newly formed unit with zinc oxide. When they compared the electrical properties of different zinc oxide nanostructures, they found significant differences.

“These are the same starting molecules, we turn them all into zinc oxide. The only difference between one and the other is how they are combined locally at the nanoscale,” said Yager. “That will be a big difference in the electrical properties of the last thing. In the sensor or electrode for the battery, this will be very important.

Scientists are now investigating the mechanical properties of different species.

“The next area is multifunctionality,” Yager said. “Now that we have access to these beautiful buildings, how do we choose which one maximizes one thing and minimizes the other – or maximizes both or slow down if that’s what we want.”

“With this system, we have a lot of control,” Yager said. “We can control what the design is (due to the newly developed system), and also what it is used for (due to our expertise in design by installation). We look forward to working with the CFN staff. work and what this path can lead to.