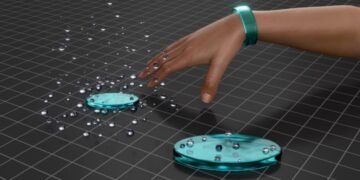

Researchers at the universities of Stuttgart and Tübingen are developing self-modifying polymers that can adapt to changes in environmental conditions. Wearable medical devices with Smart Rubber Materials, such as flexible exoskeletons that provide support to stroke patients or controlled drug delivery patches, must be objects that can be intelligently and independently adapted to movement of the patient and changing environmental conditions.

This is exactly the type of self-modifying polymer (Smart rubber materials) that scientists from the University of Stuttgart and pharmacists at the University of Tübingen have recently developed, the results of which are described in Advanced Materials Technologies, Business Journal.

A collaborative group, led by Prof. Sabine Ludwigs (Institute of Polymer Chemistry); Prof. Holger Steeb (Institute of Mechanics, MIB) and Mahadum Stuttgart; Dominique Lunter (from the Department of Pharmaceutical Technology, University of Tübingen), published a paper entitled “Autonomous Adaptation of Intelligent Humidity-Programmed Hydrogel Patches”, in which they showed how to create intelligent polymer materials, by and that the word “intelligent” refers to the fact that the properties of things can adapt themselves to the environmental conditions in which they are used.

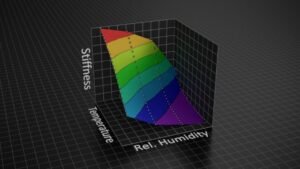

The hardness of the materials in question can change by more than four orders of magnitude with humidity and temperature, and can undergo changes even when dealing with large deformations, allowing the materials to – create something flexible and fast. One of the authors, Sabine Ludwigs, refers to these materials as “Smart Rubber Materials” and explains that: “This high flexibility makes our polymers suitable for robots made from soft materials search and rescue operations – the term here is “soft robotics“.

These polymers are also suitable for use in skin applications, such as exoskeleton and soft, flexible fabrics.” For both applications, the object will allow faster and faster. fast movement, which means it must have viscoelastic properties. “This is exactly what our invention can do”, says Holger Steeb.

A big change

In addition, the material’s water exchange capacity and water absorption capacity make it suitable for use as a barrier for controlled drug release through the skin. The researchers conducted a direct experiment on the release of diclofenac in a skin model.

“The mechanism is that it is the patch itself that controls the release of the active substance that reacts to the different levels of fluid in the wound, i.e. depending on the fluid from the wound body,” says Dominique Lunter, a clinical psychologist Tübingen, Germany.

The important research was carried out in the framework of the recently established Interfaculty Functional Soft Materials Lab (FSM Lab) within the Data-Integrated Simulation Science Cluster of Excellence at the University of Stuttgart (EXC 2075, SimTech). It is the result of an excellent collaboration between the two research groups of Sabine Ludwigs, an expert in polymer chemistry, and Holger Steeb, whose work focuses on the mechanics and functions of smart polymer materials.

Vision: Resource Responsive to Employers

In the future, researchers at the University of Stuttgart plan to study multifunctional material systems, which can adapt to their environment and react to stimuli, such as electricity.

They also plan to use simulations as a basis for designing and predicting complex architectures. For this reason, the results of research on polymeric materials also benefit from the study of the university’s “Data-Integrated Simulation Science” (SimTech)” conducted by the university.

Source: University of Stuttgart