They are considered the “holy grail” of battery research: the so-called “solid state batteries“. They no longer have liquid cores like modern batteries, but are made of solid materials. This has many advantages: among other things, these batteries are difficult to charge and can be produced in small quantities.

Scientists at the Max Planck Institute for Polymer Research have now turned their attention to the life cycle of these batteries and targeted processes to reduce it. As a result of their research, permanent solid state batteries may be available in the future.

Whether it’s an electric car, a cell phone or a cordless screwdriver, many of these everyday tools now use batteries that can break. However, the practice also has its drawbacks. For example, some mobile phones have been banned from being carried on airplanes or in electric cars that have caught fire. Modern commercial lithium-ion batteries are sensitive to operating pressure.

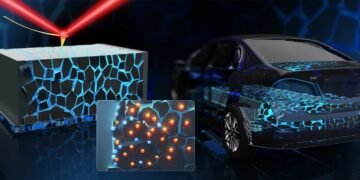

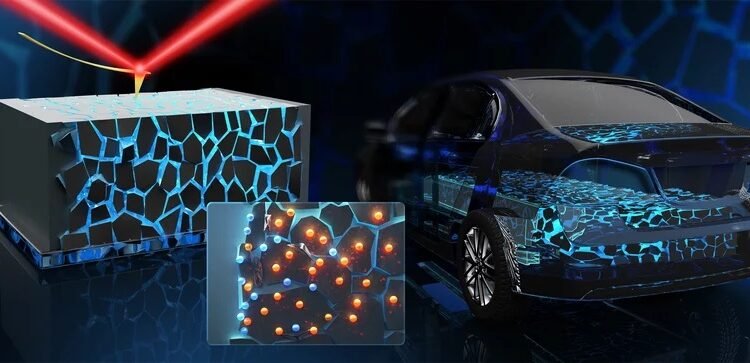

So-called “solid-state batteries” may offer a cure. These no longer contain water – the so-called electrolyte – but instead contain a solid, e.g. ceramic ion lead. As a result, they work hard, do not burn, are easy to cut and are not sensitive to temperature changes.

But solid state batteries show their problems after many charge and discharge cycles: Although the positive and negative poles of the battery are still separated from each other at first, they eventually connect together. Lithium dendrites grow slowly in batteries. These lithium dendrites grow step by step during each charging process until the two poles are connected. Result: The battery is short and “dies”. So far, however, the exact physical processes involved in this process are still poorly understood.

Rüdiger Berger’s team from the department led by Hans-Jürgen Butt has now solved the problem and studied the process in detail using special microscopy techniques. They investigated the question of where lithium dendrites begin to grow. Is it like a cave where stalactites come from the ceiling and stalagmites come from the floor until they meet in the middle and become what is called a “stalagnate”? There are no ups and downs in batteries – but do dendrites grow from negative to positive poles or from positive to negative poles? Or do they grow from these two trees? Or is there a special place in the battery that leads to nucleation and dendritic growth from there?

Rüdiger Berger’s team looked in particular at the so-called “fine grains” in solid electrolyte ceramics. These joints are created during the production of the solid layer: The atoms of the crystal of the ceramic are always fixed. However, due to small random changes in crystal growth, line-like structures form where the atoms are arranged at each point – the so-called “grain boundaries”.

The size of these grains can be seen by means of their research method – “Kelvin Probe Force Microscope” – in which the surface is examined with a sharp tip. Chao Zhu, a PhD student working with Rüdiger Berger, says: “If a solid-state battery is charged, Kelvin probe force microscopy observes that electrons accumulate in the part of the grain, especially on the part of the shaft which is not good. The latter shows that the size of the grain changes not only the arrangement of the atoms of the ceramic, but also their electrical structure.

Due to the combination of electrons – i.e. negative – the positively charged lithium ions passing through the solid electrolyte can be reduced and the lithium falls. The result: lithium deposits and lithium dendrites are formed. If the charging process is repeated, the dendrite will continue to grow until the battery is connected. The organization of such initiation processes for the growth of dendrites is found only in the negative tree – and is found only in this tree. No growth was found on healthy plants against it.

Scientists hope that with a correct understanding of the growth process, they will be able to develop effective methods to prevent or at least limit growth in unhealthy plants, so that in In the future, lithium batteries with small storage conductors can be used, and broadband applications.

Source: Max Planck Institute for Polymer Research.