Scrap metal, used for its microbial properties, is the basis for solution-based disinfectant materials. A team of scientists from Ames National Laboratory, Iowa State University and the University of Buffalo has developed an antimicrobial spray that applies a layer of copper nanowires to high-touch surfaces in public spaces. The spray contains copper nanowires (CuNW) or copper-zinc nanowires (CuZnNW) and can be an antimicrobial coating on various surfaces.

This research was initiated by the COVID-19 pandemic, but the findings have broader applications.

People have been using the antimicrobial properties of copper since 2400 BC. to treat and prevent infections and diseases. It has been shown to be effective in inactivating viruses, bacteria, molds and yeasts when in direct contact with metal. According to Jun Cui, an Ames Lab scientist and one of the project’s lead researchers, “the copper ion can penetrate the virus membrane and then insert itself into the RNA chain, completely disabling the virus from replicating.” Amid Pandemic, DOE Asks Researchers What Can You Do to Mitigate the COVID Situation? Cui said.

The Ames Lab is known for its work in materials science, not a field that often intersects with disease research. However, Cui’s team has an idea to use copper’s antimicrobial properties to reduce the spread of COVID.

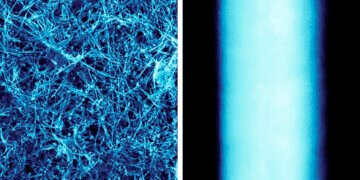

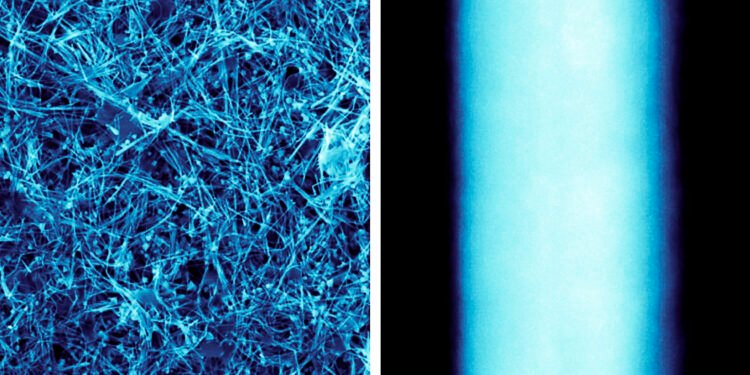

Cui explained that their idea came from a separate project they were working on, which was a copper ink designed to print copper nanowires used in flexible electronic devices. “So the idea is that it’s an ink and I can remove it with water or even ethanol and then spray it. As for the surface, I spray it once and put it on a very thin layer of copper nanowire,” he said. he said.

First, the surface must be cleaned and disinfected, then the modified copper ink solution can be applied. The ideal coating should be thin enough to be transparent. The ink can be diluted with water or alcohol to make it sprayable and can be used on plastic, glass and stainless steel surfaces.

The team tested two types of copper ink, CuNW and CuZnNW. Compared to a simple copper disc, both inks are equally effective in preventing the virus. However, the copper disk took 40 minutes to disable the virus, while the copper inks only took 20 minutes. Nanowires work faster due to their larger surface area. In a comparison between the two ink coatings, CuNW inactivated the virus faster than CuZnNW within the first 10 minutes. However, CuZnNW has a more consistent and long-term release of copper ions compared to CuNW, making the coating effective for a longer period of time.

Ultimately, the team concluded that CuZnNW is the best choice for a sprayable coating of copper nanowires for antimicrobial purposes. Cui said the work is important not only because of the pandemic, but because these nanowires can protect against many different microbes, “there’s a chance we’ll have a lasting impact on human society.”

This research is further discussed in “Sprayable Copper and Copper-Zinc Nanofiber Inks for Antiviral Surface Coatings,” C. Pan, K.S. Phadke, Z. Li, G. Ouyang, T.-h. Kim, L. Zhou, J. Slaughter, B. Bellaire, S. Ren a J. Cui a publikované v RSC Advances.