Analysts Fathom Long-Standing Challenge for Piezoelectric Materials: Heat and weight can break down the properties of piezoelectric materials that make state-of-the-art ultrasound and sonar advances conceivable – and settling that harm has truly required dismantling gadgets and uncovering the materials to indeed higher temperatures.

Presently analysts have created a procedure to reestablish those properties at room temperature, making it simpler to repair these gadgets – and clearing the way for modern ultrasound technologies.

Piezoelectric materials have numerous applications, counting sonar advances and gadgets that create and sense ultrasound waves. But for these gadgets to productively produce sonar or ultrasound waves, the fabric needs to be “poled.”

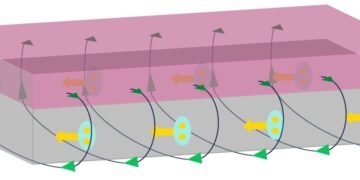

That’s since the piezoelectric materials utilized for sonar and ultrasound applications are for the most part ferroelectric. And like all ferroelectric materials, they show a marvel called unconstrained polarization. That implies they contain sets of emphatically and contrarily charged particles called dipoles. When a ferroelectric fabric is poled, that implies all of its dipoles have been pulled into arrangement with an outside electric field. In other words, the dipoles are all situated in the same course, which makes their piezoelectric properties more pronounced.

“If those dipoles aren’t in arrangement it’s troublesome to create focused on ultrasound waves with the plentifulness required for them to be practical,” says Xiaoning Jiang, comparing creator of a paper on the work and Dignitary F. Duncan Recognized Teacher of Mechanical and Aviation Designing at North Carolina State University.

“Preserving the poling of piezoelectric-ferroelectric materials postures a few critical challenges, since the dipoles can start losing their arrangement when uncovered to lifted temperatures or tall pressures,” Jiang says.

“This is moreover a fabricating issue, since it limits which other materials and forms you can utilize when making ultrasound devices,” Jiang says. “And since the raised temperatures aren’t indeed truly that tall – you can see arrangement issues as moo as 70 degrees Celsius – indeed shipping or putting away these advances can now and then unfavorably influence the poling and the effectiveness of the devices.

“What’s more, expanded utilize of a few innovations can result in the gadget itself creating warm that dangers depoling the piezoelectric-ferroelectric material.”

And once the dipoles in the fabric have come out of arrangement, getting them back into arrangement isn’t simple. The piezoelectric-ferroelectric fabric needs to be expelled from the gadget and uncovered to tall warm – 300 degrees Celsius or more – in arrange to totally depole the fabric some time recently “repoling” it and pulling the dipoles back into alignment.

“It’s critical to re-use these piezoelectric-ferroelectric materials since they are as a rule costly – you don’t need to fair toss them away,” Jiang says. “But regularly the fabric is recovered and the rest of the ultrasound gadget is discarded.

“We have created a strategy that permits us to depole and repole piezoelectric-ferroelectric materials at room temperature. That implies we can drag the dipoles back into arrangement without evacuating the fabric from the gadget – and this can be done more than once, as needed.”

To get it the unused procedure, you require to get it that there are two ways to drag the dipoles in a piezoelectric-ferroelectric fabric into arrangement. The most broadly utilized strategy includes applying a coordinate current (DC) electric field to the fabric, which pulls all of the dipoles in the same direction.

“This way works well for making arrangement, but it is essentially inconceivable to depole the fabric utilizing as it were a DC field,” Jiang said.

The other strategy includes applying an substituting current (AC) electric field to the fabric, which causes the dipoles to waver in reaction to the waves in the field, until the field is expelled, at which point the dipoles bolt into put in alignment.

“We found that we can too depole the fabric utilizing an AC field, indeed at room temperature. If the fabric was initially poled utilizing a DC field, we might expel much of the poling with an AC field – but not all of it,” Jiang said. “However, if the fabric was initially poled with an AC field, we found that seem moreover totally depole the fabric utilizing an AC field.”

The finding has at slightest two noteworthy consequences for ultrasound technologies.

“If we can shaft piezoelectric-ferroelectric materials at room temperature, it implies we can modify the other materials and fabricating forms we utilize when making ultrasound gadgets to optimize their performance,” Jiang says. “We are no longer restricted to materials and forms that won’t influence the polarization in the piezoelectric-ferroelectric components, since we can shaft the fabric utilizing an AC field after the gadget has been assembled.

“What’s more, it implies that we can effectively repole the materials in existing gadgets, ideally giving us a long lifetime of crest execution for these technologies.”

Courtesy: North Carolina State University.