Photonics, It’s a matter of knowing. This technology uses light instead of electricity. It’s fast; it is spacious; and it is poised to be the next big advance in human technology.

Until now, photonics research required expensive and sophisticated equipment such as precision lasers and custom circuits. But to realize its full potential, the technology must be small, cheap and easy to manufacture.

Researchers have made progress in these areas, but they are still struggling to make their circuits work with shorter wavelengths of light.

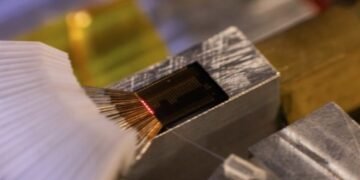

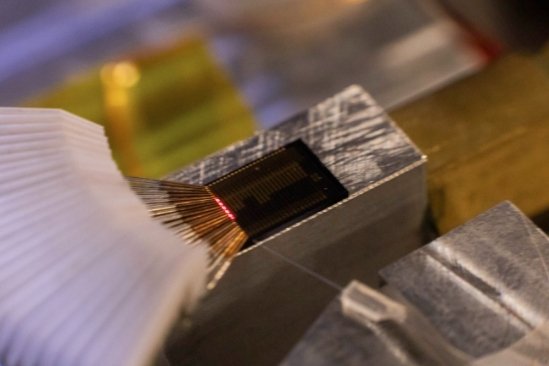

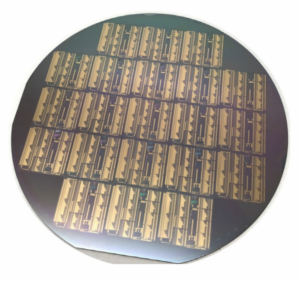

In a discovery (Extend the Spectrum) that promises to make these things smaller and more powerful, a team from Nexus Photonics, UC Santa Barbara and Caltech has developed a process that allows photonic chips to operate near optical -infrared spectrum. The system also uses conventional methods in electronic manufacturing, which allows mass production at low cost.

The results appear in the journal Nature.

“This is the kind of breakthrough that can open up opportunities that no one has ever thought of,” said Ted Morin a graduate student at UC Santa Barbara. The technology will allow advanced photonics with high performance to reach markets and new applications, such as improvements in virtual reality, health, and atomic clocks in the near-infrared wavelengths. In addition, mass production will reduce the price of lasers and photonic circuits. “It would be like getting a boat for the price of a boat,” Morin said.

Human progress over the past half century has been accompanied by advances in electronics, which are becoming smaller and more powerful. “People have put together an amazing feat of making electronic circuits smaller, faster and more reliable,” Morin said. “We are looking for ways to use electronic circuit manufacturing technology to create photonic circuits.”

Light and energy information is transmitted by wave propagation in photonic circuits, just like electricity through wires in electronic circuits. The biggest hurdle in miniaturization has been connecting the laser to the photonic circuit itself. But applying it to any channel is not effective. “Imagine that someone is putting wires, by hand, into a few transistors in your computer setup,” Morin said.

“It would completely defeat the purpose of making things compact,” added lead author Minh Tran, Director of research at Nexus Photonics, who received his Ph.D. from UC Santa Barbara.

Researchers at UC Santa Barbara, led by Professor John Bowers, successfully solved the “laser bonding” problem for silicon circuits in 2005. They overcame this obstacle by bonding a laser on top of the silicon and sending light down the ship wind. Many industrial and research companies developed this technology in its various forms, and Intel sells it for several million dollars a year.

Unfortunately, these solutions have limitations. They only work for light with a wavelength greater than 1,100 nanometers, which is deep in the infrared. Each semiconductor has a so-called “bandgap energy“, and photons with higher energy (ie, shorter wavelength) than the one absorbed. The band gap of silicon is around 1100 nm. “So anything shorter than that doesn’t work with technology right now,” Tran said. Visible light ranges from 380 to 750 nm, which means that UV, visible light and even some infrared are absorbed through silicon waveguides.

So, while silicon is great for electronics, it can’t transmit light at the wavelengths that scientists and engineers need. “If we want to extend our device to a shorter distance, we need to use a different material to direct our light,” explained Tran.

Silicon nitride stands out as the best candidate. The wavelength of the material is about 250 nm, well into the ultraviolet part of the spectrum. And because it is a silicon compound, it easily integrates into the electronic production process. Its components, silicon and nitrogen, are also abundant and cheap. “Really, it’s sand plus air,” Morin said. And the whole process includes regular manufacturing processes and can be easily extended with existing equipment.

And now, the challenge of combining lasers with waveguides must be met, because the original silicon process does not work with silicon nitride due to its optical properties. Light travels at different speeds depending on what it passes through. Scientists describe the speed of light in a material with a number called the refractive index, and silicon nitride has a very different direction than the laser material. This makes it difficult to distort the truth.

To solve this problem, the team added a medium with a refractive index close to silicon nitride in the same plane as the laser. In this way, the laser light can enter the turning point and direct it to the silicon nitride through a parallel optical element. But while the design is a step forward, the real challenge is to adapt the process to the electronics manufacturing process, Tran explained.

This achievement marks a big step forward for the team. “In 2018, many of us at UCSB founded Nexus Photonics to solve the challenge of creating photonic integrated circuits,” said founder and CEO Tin Komljenovic. “Now, we’ve finally advanced the technology to the point where it’s doing the work of a large business process while costing less than a penny.”

“This is a very important step in the field of semiconductors and photonics,” added Chong Zhang, a graduate of UC Santa Barbara and lead author, co-founder and president of engineering at Nexus Photonics. “It provides a feasible and scalable solution, for the first time, for full-scale photonic integration in the optical and near-infrared wavelengths.”

Laser coupling techniques will enable high precision photonics to be more affordable. As a result, they will have access to researchers, engineers to develop better technology, and perhaps even electronics. After all, miniature photonic circuits are precisely the kind of hardware that can be put into commercial applications.

There are all kinds of applications, explain the authors. This technology may find its way into biomedical science through applications such as biosensing and DNA sequencing. It will open new avenues for atomic physics and quantum research. “The use of commercial silicon facilities will mean that any university professor in any school in the world will be able to access equipment and perform experiments that are currently possible in large research facilities,” said Morin. Morin said.

“We are supporting access to quantum physics,” added Tran.

Photonics can also revolutionize virtual and augmented reality. “With integrated photonics, it’s possible to get light from a small chip and send it in a very controlled direction,” Morin said. “By quickly scrolling the direction, you can quickly produce images.

“You can also find out where the fire came from a single explosion,” he continued. “So it’s possible to turn on the light somewhere and see what comes back in a very small package.” It’s the idea behind lidar, the laser equivalent of radar, that is changing our driving experience.

The team has successfully incorporated photonics into the electronics industry and is already considering its next challenge. Finally, they plan to combine photonic and electronic circuits on a single chip, which will achieve even greater cost and energy efficiency.