In the search for clean and renewable energy, hydrogen plays an important role. But the biggest challenge in this transformation is that the gas explodes when mixed with air. For this reason, it is important to be able to detect liquid hydrogen as soon as possible. Now researchers from Chalmers University of Technology, Vrije Universiteit Amsterdam and Eindhoven University of Technology have developed an High-sensitivity optical sensors can detect and reduce hydrogen hazards.

Hydrogen is seen as an important part of disrupting the heavy transport sector around the world as hydrogen trains, trucks and airplanes are being developed. Even in heavy industry, hydrogen is considered very important, for example for the production of stainless steel.

The risks associated with the storage or use of hydrogen are well known. Only four percent of hydrogen is required in the air to produce an explosive mixture (knallgas) that can be ignited with a small flame. Therefore, it is important that High-sensitivity optical sensors are in place to monitor leakage and alertness at critical levels.

Safety is paramount in using hydrogen

Together with Dutch colleagues, researchers from the Department of Physics at Chalmers University of Technology, Sweden, have developed an optical hydrogen sensor that detects record levels of hydrogen. So it joins the world’s most sensitive sensors. The results of the new research are presented in the Nature Communications article.

“Safety is paramount in all uses and storage of hydrogen. If the leaks are caught early, they can be repaired so that you don’t have to take the plant or the vehicle out of service at all,” says Chalmers Professor Christoph Langhammer, one of the The leading author of the scientific paper says.

AI technology opens the door

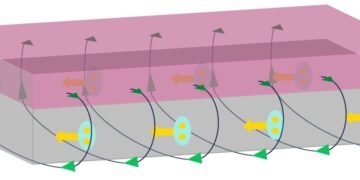

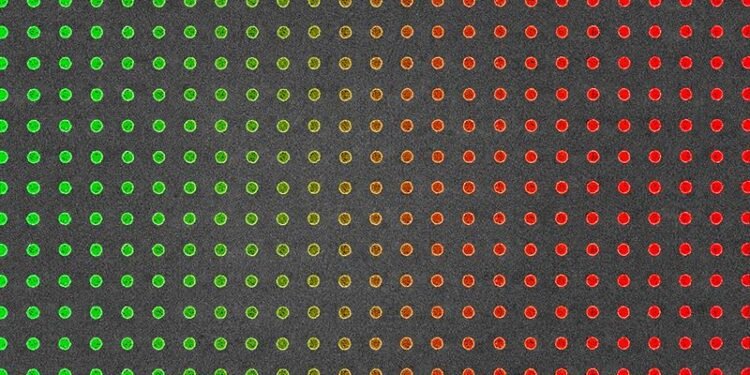

An optical hydrogen sensor consists of several nanoparticles that work together to detect hydrogen in their environment. The design process of the new sensor is different from the previous one. Instead of creating a large number of samples and testing them one by one to find the best one, the researchers used advanced AI technology to make a good relationship between different objects based on their distance, diameter and their thickness. The result is a sensor that detects changes in hydrogen concentration as small as a few hundred thousandths of a percent.

The secret to the low detection limit of the new sensor (High-sensitivity optical sensors) is the combination of the structure of the material that makes it common on the surface and their changing angles. This proved to be better for sensing than the molecular structure used in previous sensors of the same type.

Christoph Langhammer’s research team has developed the world’s fastest hydrogen sensor. Therefore, it is clear that many different types of sensors are needed and that they must be configured for the application.

“Hydrogen technology has come a long way, so modern sensors need to be precise and suitable for different purposes. Sometimes you want a fast sensor, sometimes you want one that works with harsh chemicals or low temperatures. One sensor cannot meet all needs,” says Christoph Langhammer, who is also one of the founders of a new license company: TechForH2.

Industry and education in the new hydrogen partnership

The new Chalmers-led center brings together both academia and industry to develop new hydrogen technologies with a focus on decarbonizing heavy-duty transport systems. TechForH2 is led by Tomas Grönstedt, professor at the Department of Mechanics and Marine Sciences at Chalmers.

When the research community and the industry come together, it can make us go to the next level, so that what we create can be applied and meet the needs and problems in the industry. the development of sensors is affected, as well as research related to it. the propulsion of cars or airplanes that use hydrogen”, explains Tomas Grönstedt, who said that the electric plane with a range of about 500 km has able to increase its altitude of 3,000 kilometers if fueled by hydrogen.

How does a hydrogen water sensor work?

The sensors developed by the researchers are based on optical properties, plasmons, which occur when the nanoparticles fall to pick up the light and give different parts of the body. If the nanoparticles are made of palladium or palladium alloy, their color changes when the amount of hydrogen in the environment changes, the sensor can trigger an alarm if the level is too critical.

To find the best combination of surface structure and particle geometry in the sensor, the researchers used human intelligence to perform a function called optimization of the value of the swarm to achieve the highest effect and exposure to hydrogen. Placing the particles in a well-defined order always proved to be the solution.

Based on AI’s design, an improved optical hydrogen sensor was developed and proved to be the first of its kind to detect hydrogen at “parts per billion” (250 ppb).