Discovered in 2004, graphene has revolutionized various scientific fields. It has remarkable properties such as high electron mobility, high tensile strength and thermal conductivity. Much time and effort has been invested in exploring its potential as a next-generation (Laser Induced Monolayer Graphene Nanoprocessing) semiconductor material, leading to the development of graphene-based transistors, transparent electrodes, and sensors.

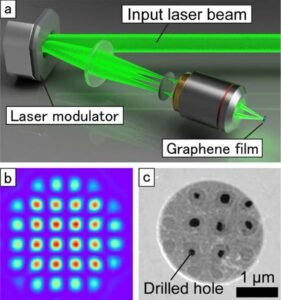

But in order to bring these devices into practical use, it is necessary to have an effective processing method that can organize graphene films at the micrometer and nanometer scale. Typically, micro/nano signal processing and device fabrication use nanolithography and focused ion beam methods. However, these have long posed challenges to laboratory researchers due to their need for large equipment, long manufacturing times and difficult operations.

Last January, researchers at Tohoku University developed a process that can produce small silicon nitride devices with a thickness ranging from 5 to 50 nanometers. The process uses a femtosecond laser, which emits a short and fast light. He turned out to be able to quickly arrange the equipment without the space.

By applying this technique to the thin atomic layers of graphene, the team has now succeeded in extracting various holes without damaging the graphene film.

Details of their breakthrough were reported in the journal Nano Letters on May 16, 2023.

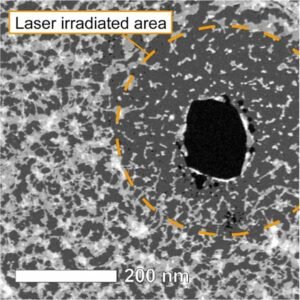

“With proper control of the input energy and the number of laser shots, we were able to execute precise machining and create holes with diameters ranging from 70 nm (much smaller than the laser wavelength of 520 nm) to over 1 millimeter,” said Yuuki Uesugi, assistant professor at the Multidisciplinary Research Institute of Advanced Materials, Tohoku University, and co-author of the paper.

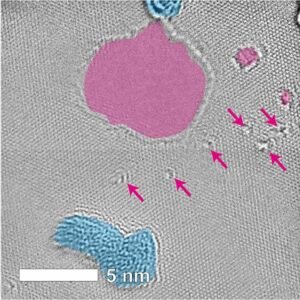

After further examination of the low laser beam area, which did not create a hole, through a high-performance electron microscope, Uesugi and his colleagues found that the contaminants had also been removed from the graphene. Further analysis revealed nanopores less than 10 nanometers in diameter and defects at the atomic level, where most carbon atoms are missing from the graphene crystals.

Dotted atoms in graphene are both destructive and useful, depending on the application. While bugs sometimes degrade certain features, they introduce new features or improve specific features.

“Observations for the density of nanopores and dots increase in proportion to the power and number of laser shots led us to conclude that the structure of nanopores and dots can be manipulated using femtosecond laser irradiation,” Uesugi says to add. “By creating nanopores and atomic dots in graphene, not only electricity can be controlled, but also quantum level properties such as spin and valleys.

In addition, the removal of contamination by femtosecond laser irradiation found in this research can create a new method to clean pure graphene without destruction and efficiently.

For the future, the team aims to establish a cleaning process using lasers to carry out a detailed study of how the formation of atomic defects. Further advances will have a major impact in areas ranging from materials analysis to biosensor development.

Source: Tohoku University